Melting repair method for repairing cracks of stainless steel workpiece

A stainless steel and workpiece technology, applied in the field of fusion repair for stainless steel workpiece crack repair, can solve the problems of easy deformation, falling off, cracking and other problems at the welding point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

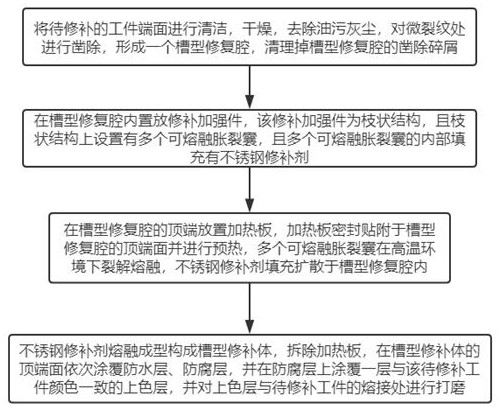

[0041] see figure 1 , a stainless steel workpiece crack repair method for fusion repair, the specific method steps are as follows:

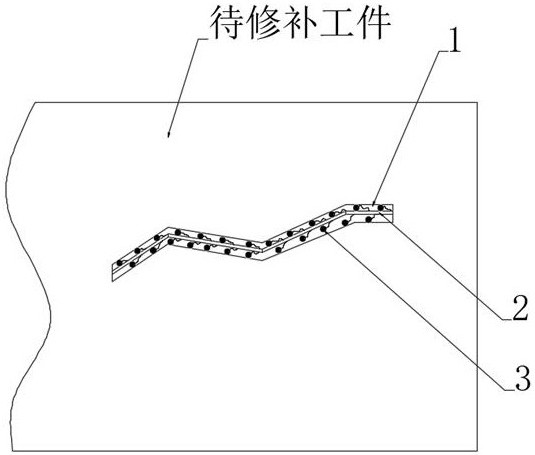

[0042] S1. Clean and dry the end face of the workpiece to be repaired, remove oil and dust, chisel away the micro-cracks to form a groove repair cavity 1, and clean up the chiseled debris in the groove repair cavity 1;

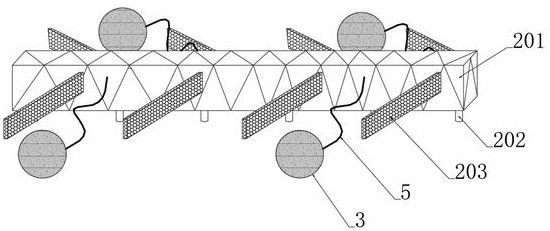

[0043] S2. Put a repair reinforcement 2 in the groove repair cavity, the repair reinforcement 2 is a dendritic structure, and a plurality of meltable and burstable capsules 3 are arranged on the dendritic structure, and the plurality of meltable and burstable capsules 3 The interior is filled with stainless steel repair agent 4;

[0044] S3. A heating plate is placed on the top of the groove repair cavity 1, and the heating plate is sealed and attached to the top surface of the groove repair cavity 1 and preheated. A plurality of meltable and burstable capsules 3 are cracked and melted in a high temperature environment, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com