Concrete bridge deck crack repairing method for bridge

A technology for repairing cracks and concrete, which is applied in bridge maintenance, bridges, bridge parts, etc. It can solve problems such as small crack space, low repair strength, and concrete swelling, so as to promote filling compaction, improve repair strength, and improve positioning and reinforcement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

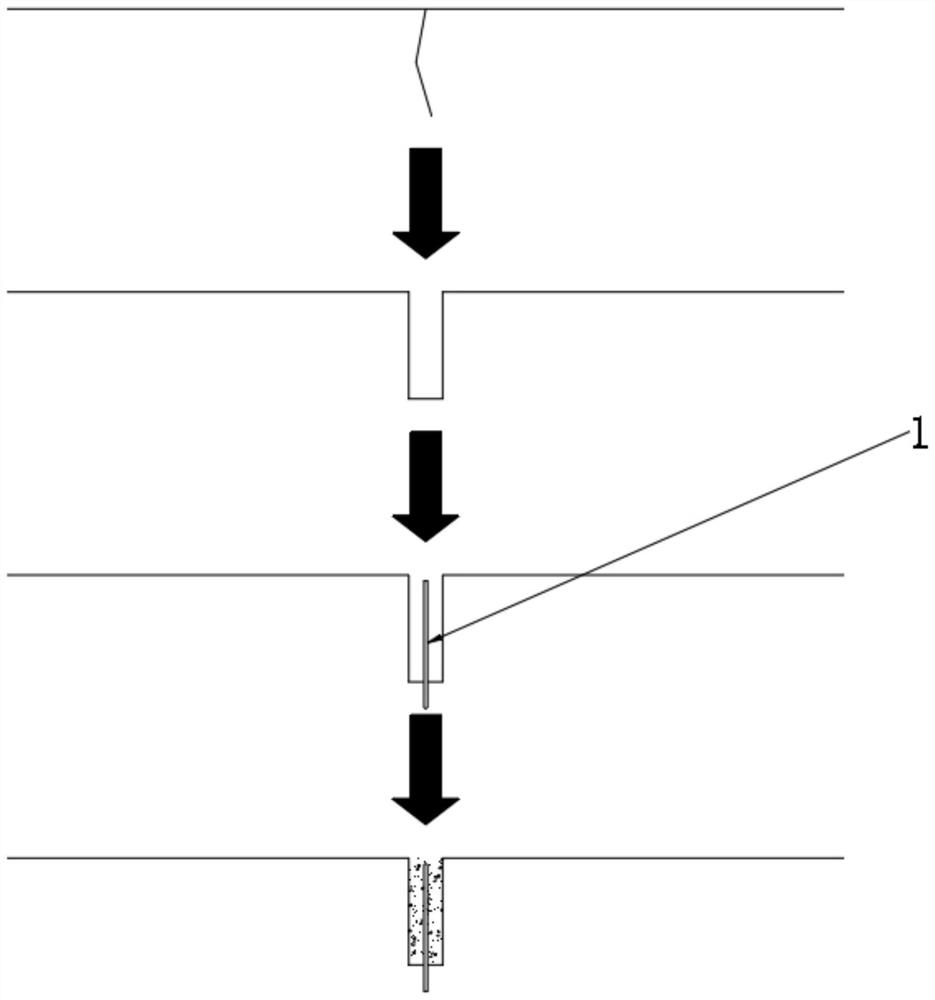

[0044] see figure 1 , a bridge concrete deck crack repair method, comprising the following steps:

[0045] S1. Determine the size of the slot according to the size of the crack, and expand the slot through the slotting machine. The crack width is controlled between 1.5-2cm;

[0046] S2. Drill pre-buried holes evenly on the bottom wall of the crack, and then use a high-power blower or hot air gun to purge for 1-2 times, and then purge a small amount of debris and sundries in the groove. If it is, use a special hook to clean it manually, and then blow it again after cleaning to ensure that the seam is absolutely dry and clean;

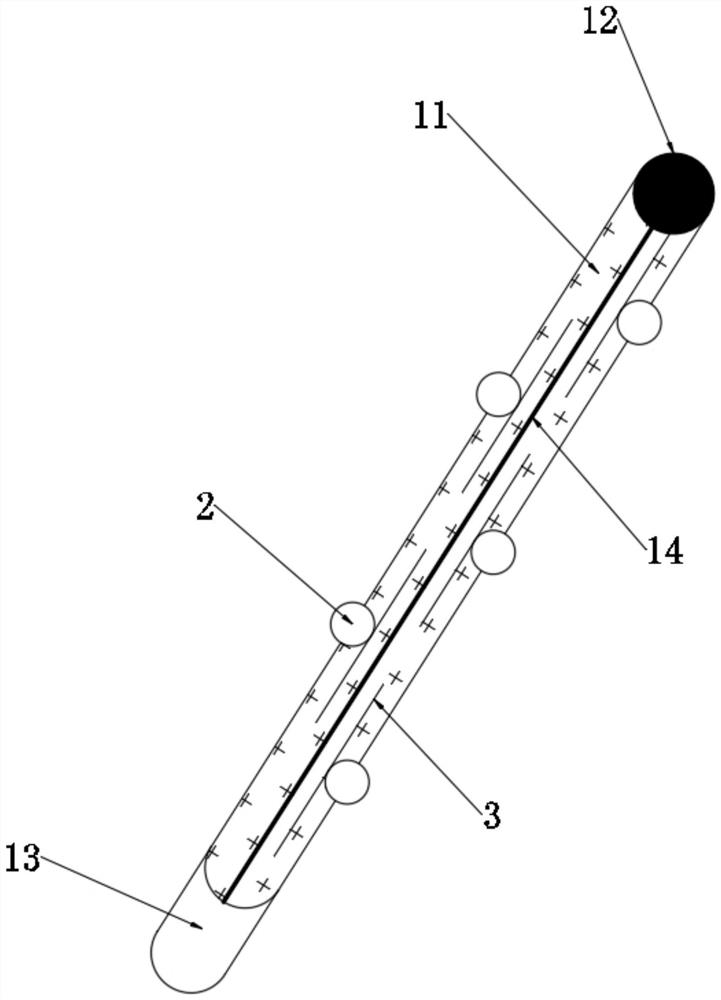

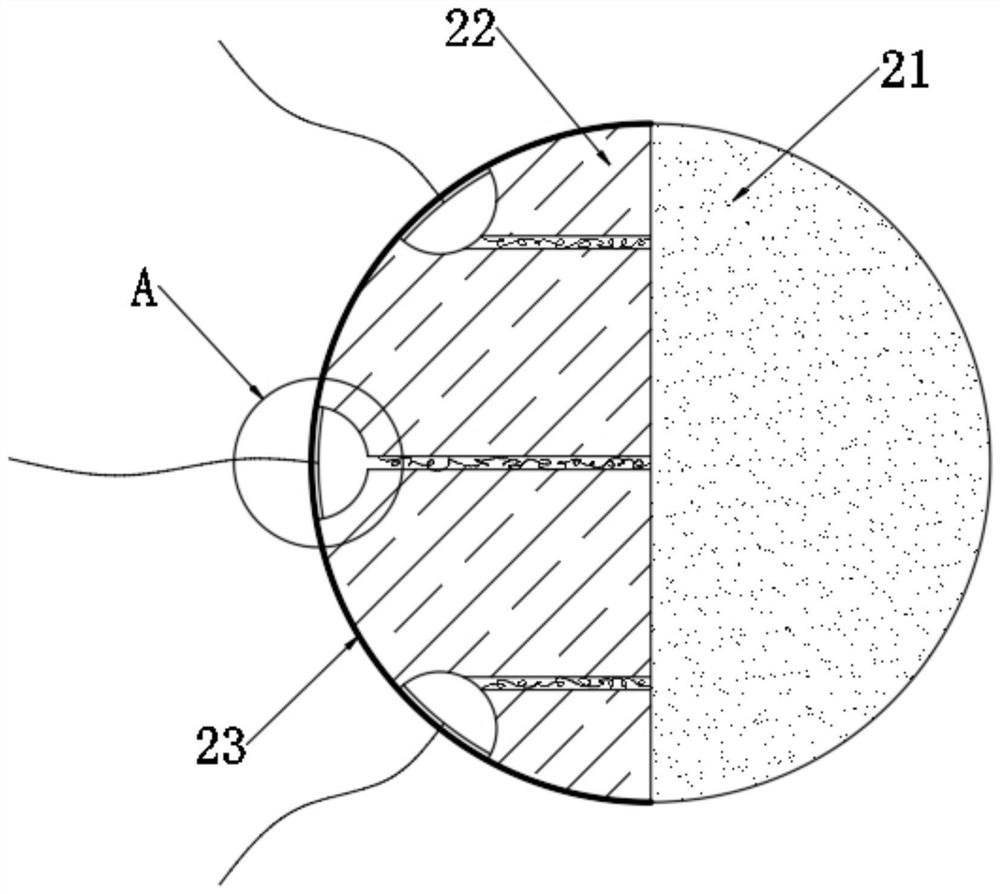

[0047] S3. Insert the defoaming rod 1 into the pre-embedded hole and temporarily fix it, and then pour the repairing concrete into the crack until the crack is full;

[0048] S4. Insert multiple air ducts deep into the concrete, then fill the air ducts with oxygen, discharge the air in the concrete, and then seal the cracks;

[0049] S5. Applying a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com