Reinforced composite board and production technology thereof

A composite board and reinforced technology, which is applied in the fields of refrigeration, board, freezer, temporary building, and road sound insulation wall, can solve the problems of core material fracture, adhesion deviation, etc., achieve low cost, improve stretchability, The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0020] Use professional equipment to directly foam and compound galvanized color steel plates to form roof panels and sandwich wall panels. The process steps include:

[0021] 1) First, the steel plate is made into a color steel plate through baking paint treatment;

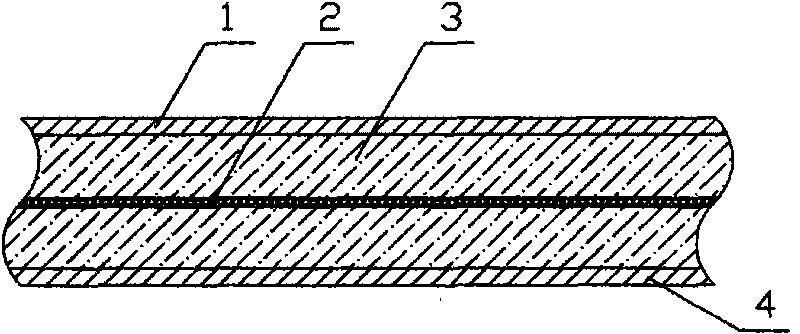

[0022] 2) Spread more than one reinforcement layer between the upper and lower color steel layers or between the color steel layer and the decorative material layer, and then evenly spray on the reinforcement layer based on phenolic resin, with a curing agent, emulsified Additives such as additives are directly foamed to form a fireproof material layer;

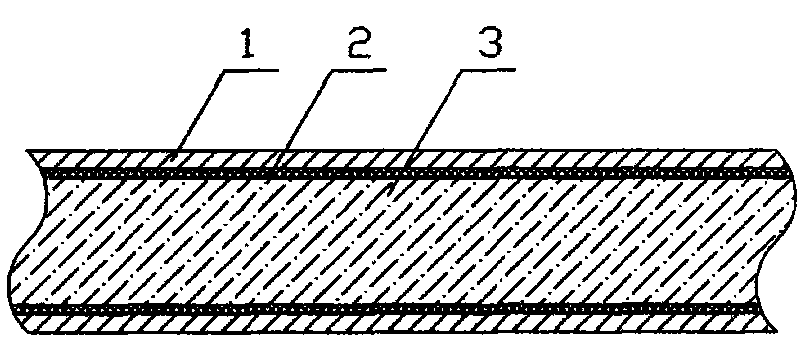

[0023] 3) In the process of phenolic foaming, the reinforcement layer is distributed in the middle of the phenolic foam or on both sides of the phenolic foam;

[0024] 4), baking;

[0025] 5), the final product.

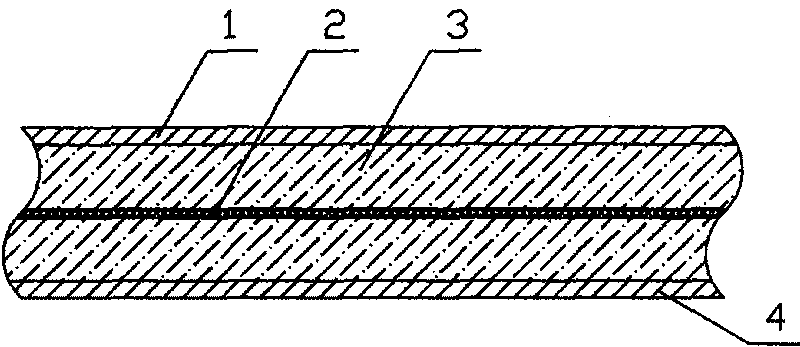

[0026] see figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com