A wire drawing process and application of starch degradable plastic

A technology for degrading plastics and starches, applied in filament forming treatment, textile and papermaking, melt spinning, etc., can solve the problems of poor processing performance, short life, difficult to popularize and apply on a large scale, improve processing performance, strengthen mechanical performance, the effect of improving the pulling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

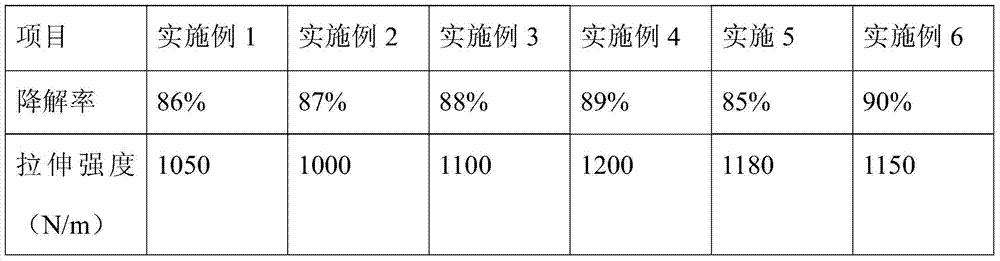

Examples

Embodiment 1

[0016] A wire drawing process of starch degradable plastics, comprising the following steps:

[0017] 1) First, weigh the starch-degradable plastic with a weight percentage of 90%, the isocyanate compatibilizer with a weight percentage of 0.5%, and the acrylic acid additive with a weight percentage of 9.5%, and mix the above-mentioned starch-degradable plastic and isocyanate compatibilizer and acrylic acid additives were stirred evenly at 40°C;

[0018] 2) Heating the uniformly stirred material in step 1 in a single-screw extruder, extruding monofilament or flat filament at 120°C.

[0019] Among them, compatibilizers and additives make the chemical bonds of starch degradable plastics form double bonds, and the intermolecular double bonds polymerize to strengthen the connection between molecular chains, which is beneficial to the longitudinal arrangement between molecular chains, thereby improving the degradability of starch. The tensile properties, strength and flexibility of...

Embodiment 2

[0021] A wire drawing process of starch degradable plastics, comprising the following steps:

[0022] 1) First, weigh the starch-degradable plastic with a weight percentage of 99%, the titanate compatibilizer with a weight percentage of 0.5%, and the acetoacrylic acid additive with a weight percentage of 0.5%, and mix the above-mentioned starch-degradable plastic, titanium Stir the ester compatibilizer and acetoacrylic acid additives evenly at 70°C;

[0023] 2) Heating the uniformly stirred material in step 1 in a single-screw extruder, extruding monofilament or flat filament at 220°C.

Embodiment 3

[0025] A wire drawing process of starch degradable plastics, comprising the following steps:

[0026] 1) First, weigh the starch-degradable plastic with a weight percentage of 80%, the methyl acrylate compatibilizer with a weight percentage of 10%, and the polyester acrylic acid additive with a weight percentage of 10%, and mix the above-mentioned starch-degradable plastic, Methyl acrylate compatibilizer and polyester acrylic additive are stirred evenly at 50°C;

[0027] 2) Heating the uniformly stirred material in step 1 in a single-screw extruder, extruding monofilament or flat filament at 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com