High-carbon steel wire rod low in network cementite precipitation and used for fine wire drawing and production method of high-carbon steel wire rod

A cementite and high-carbon steel technology, applied in the field of low-reticular cementite precipitation of high-carbon steel wire rod, can solve the problems of undefined control method of wire rod structure

Inactive Publication Date: 2018-08-14

ANGANG STEEL CO LTD

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The above-mentioned patent only introduces the control process of the steelmaking process, focusing on the control of the Al content of the inclusions in the steel 2 o 3 content, the control method of wire rod structure is not specified

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

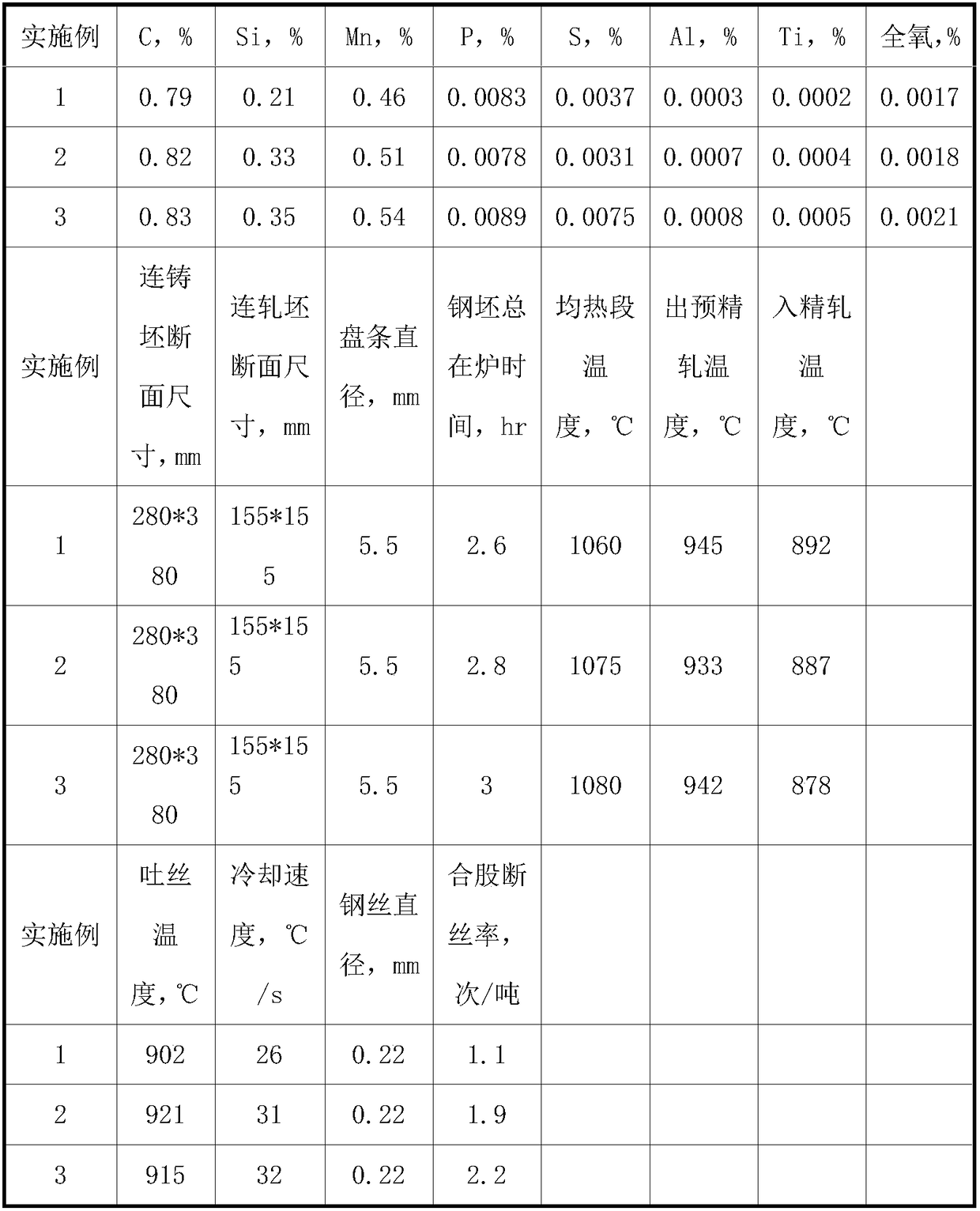

[0024] Below in conjunction with embodiment the present invention is described in detail.

[0025] From figure 1 It can be seen that the structure of the wire rod in Example 3 is mainly sorbite, and there is no precipitation of reticular cementite.

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-carbon steel wire rod low in network cementite precipitation and used for fine wire drawing and a production method of the high-carbon steel wire rod. The high-carbon steel wire rod comprises 0.79%-0.84% of C, 0.20%-0.40% of Si, 0.45%-0.55% of Mn, smaller than or equal to 0.010% of P, 0.0020%-0.010% of S, 0.0005%-0.00010% of Al, 0.0002%-0.0006% of Ti, 0.0015%-0.0025%of total oxygen and the balance Fe and inevitable impurities. The high-carbon steel wire rod is used for producing a fine steel wire with the diameter being 0.22 mm, the breaking rate of a produced steel wire cord thread is not larger than 3 times / ton, and the using requirement of a user is met.

Description

technical field [0001] The invention belongs to the technical field of iron and steel products, and in particular relates to a high-carbon steel wire rod with low mesh cementite precipitation and a production method thereof for filament drawing. Background technique [0002] As the market competition in the field of domestic metal products continues to intensify, manufacturers have continuously increased their requirements for the quality of raw materials for metal products. Especially for high-carbon steel wire rods used for filament drawing, the wire rod rolling process has a great influence on the structure of the wire rod and the properties of the drawn and processed products, so strict control is required. The reticular cementite in the wire rod structure is a brittle structure, which has an adverse effect on the wire breakage rate of the wire rod during the filament drawing process, and will deteriorate the fatigue life of the steel wire products such as thin steel rop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/14C21D8/06

CPCC22C38/02C21D8/065C22C38/002C22C38/04C22C38/06C22C38/14

Inventor 郭大勇高航赵学博王秉喜张博马立国常宏伟

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com