Tungsten carbide-titanium carbide-tantalum carbide solid solution powder

A solid solution and titanium carbide technology, applied in the field of metal materials, can solve the problems of high price, influence and limitation of industrial modernization process, and achieve the effect of reducing product particle size, increasing reaction speed and conversion rate, and reducing activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

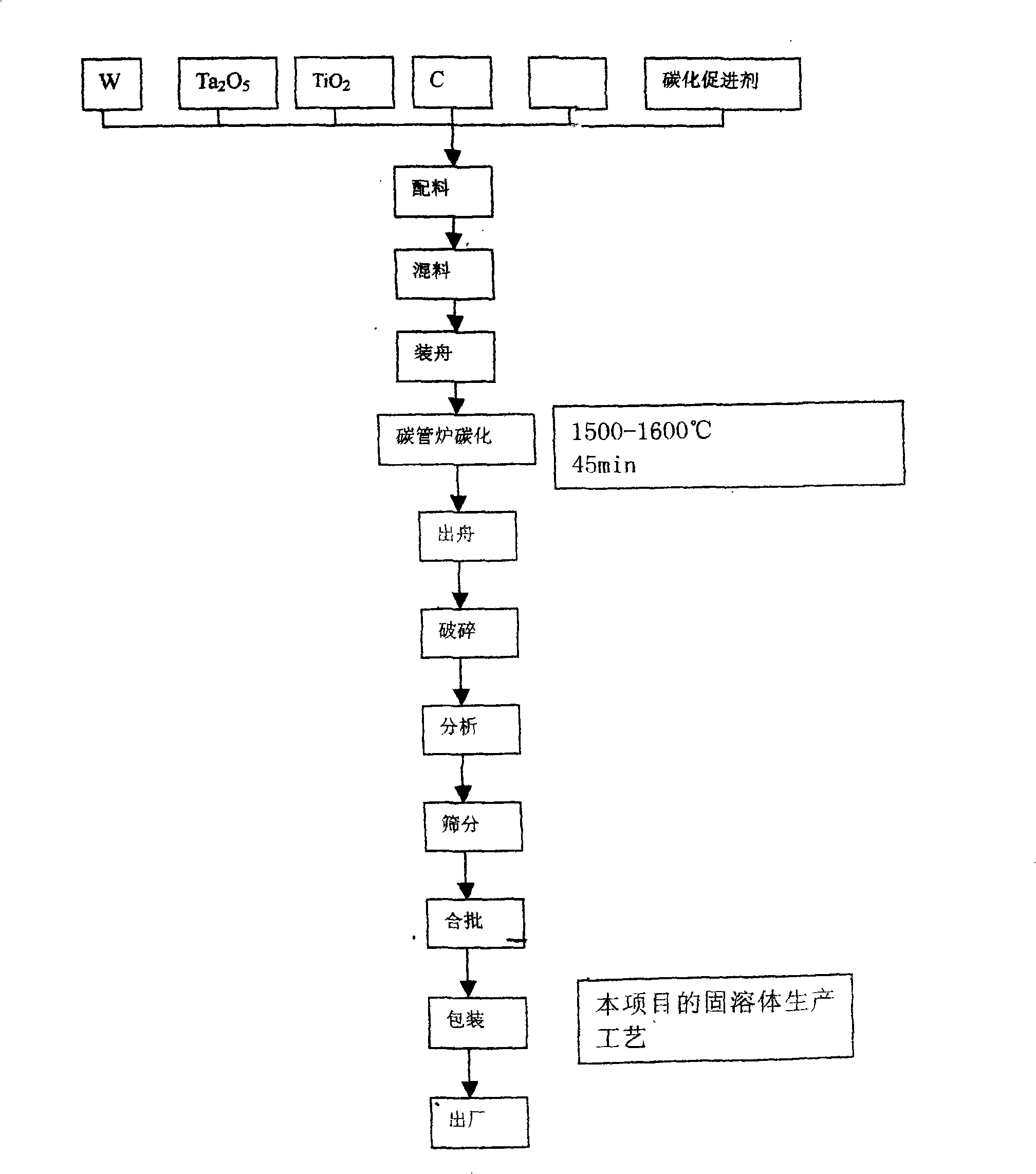

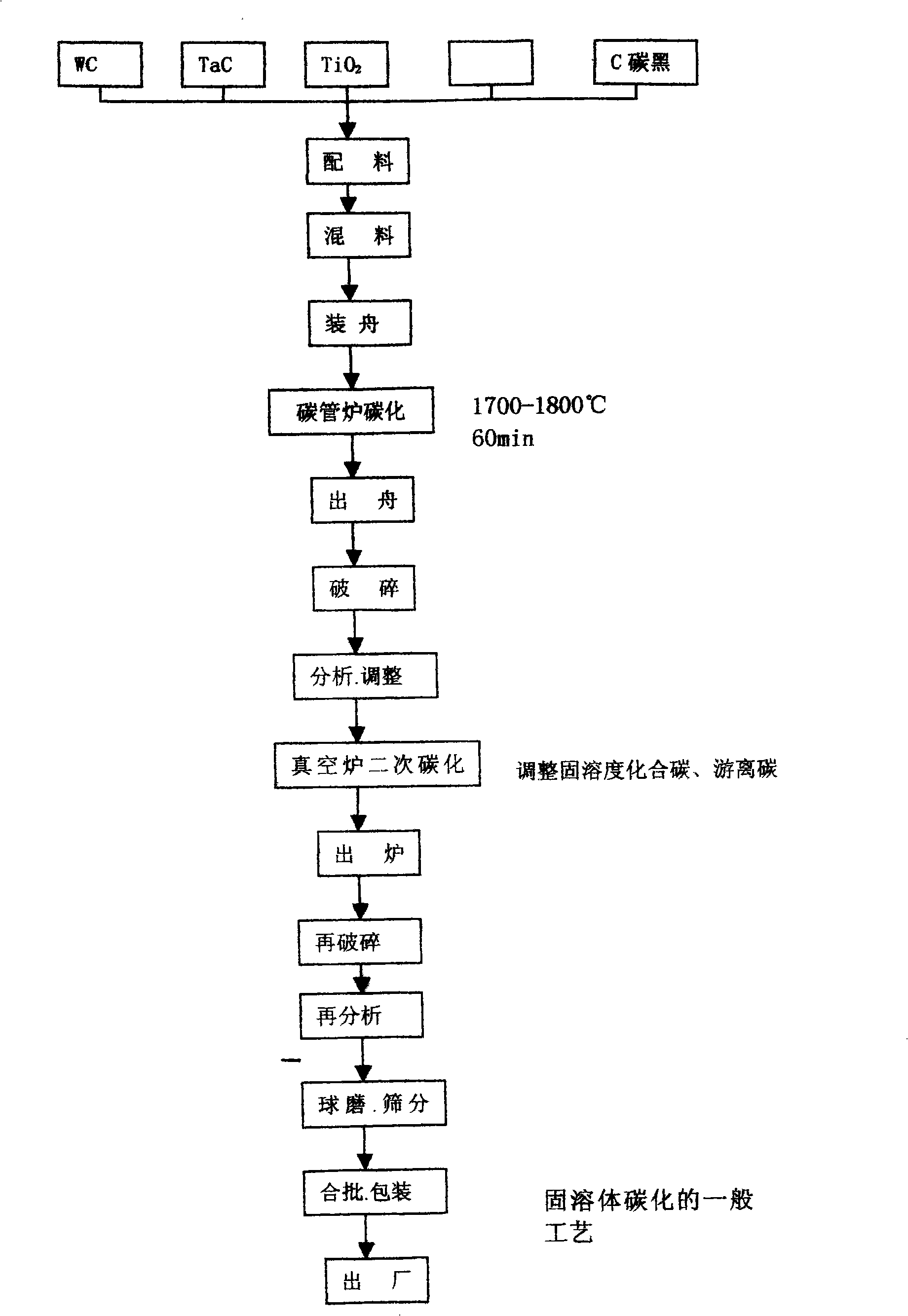

Method used

Image

Examples

Embodiment 1

[0029] Example 1: In a domestic joint-stock company, the self-made WC-TiC-TaC solid solution has been used to produce a foreign turning tool (CL26417) on the eve of 2005. Due to the increase of the cutting speed of the user, the steel grade of the processed material Changes, the life of the tool cannot meet the requirements. Users have to use imported tools to meet production needs. When the company's scientific research personnel switched to our company's solid solution TRC-33, the life of the tool was greatly improved, and it could completely replace imported tools to meet the production requirements of users, and was well received by users. At present, the product has been mass-produced for more than three years, creating more than 10 million yuan in revenue for the enterprise.

Embodiment 2

[0030] Embodiment 2: Application of TRC-33 in threaded comb cutter base blank:

[0031] High-strength oil pipes are difficult-to-machine materials, and the requirements for the blade matrix material are very high. Due to the user's substantial increase in cutting speed, the comb base material that has been used for many years can no longer meet the user's production requirements, so it is urgent to develop a new material to replace the old basic material. After repeated screening by scientific researchers, the alloy-based material with TRC-33 solid solution was finally selected to meet the needs of users. After adding TRC-33 solid solution, the overall material performance of WC-TiC-TaC-Co alloy is superior, and the product quality is stable. Many times of cutting tests show that the service life of the blade produced by TRC-33 solid solution is longer than that of similar products produced by a famous brand factory purchased by the company, and the independent production of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com