Method for producing water-grinding glutinous rice flour

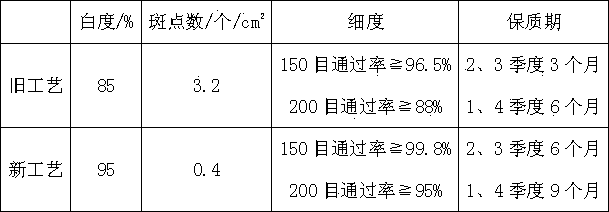

A technology for water-milling glutinous rice flour and a production method, which is applied in the fields of application, food preparation, food science, etc., can solve the problems that the product quality cannot be fully and reliably guaranteed, the water-grinding glutinous rice flour product is stubborn, and the service life is shortened, and the fineness is achieved. High, low cost, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

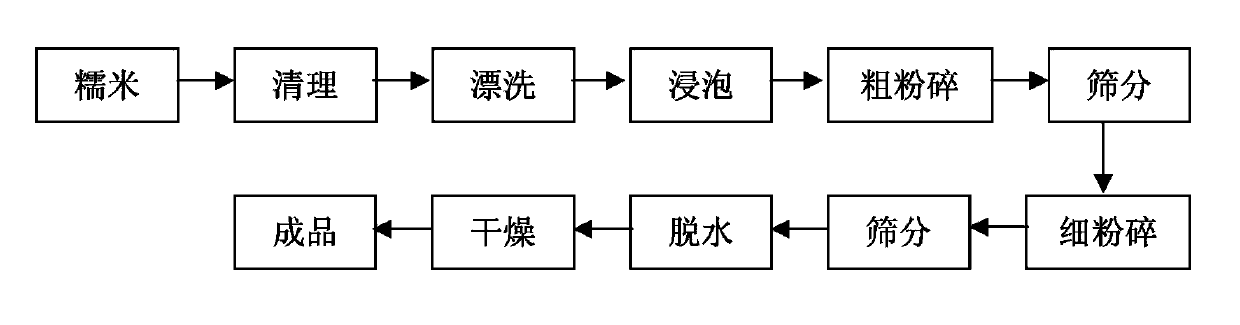

[0021] see figure 1 , the method for producing water-milled glutinous rice flour of the present invention realizes the production of water-milled glutinous rice flour and can make higher-quality water-milled glutinous rice flour through the improvement of the crushing process in the water-milled glutinous rice flour production process.

[0022] First, the ash and impurities in the rice are removed in the pre-treatment process, so that the rice can fully absorb water and swell to reduce the crushing resistance. Then, for the soaked glutinous rice, first use a pulverizer for coarse crushing, and use a vibrating sieving machine for the first screening , remove the glutinous rice bran in the rice milk to obtain a 50-80 mesh slurry; then use an ultra-fine pulverizer to carry out fine grinding, and use a vibrating screen to carry out a second screening, so that the ground rice milk particles are all within 100 Mesh or above; finally, the rice milk is dehydrated and dried to obtain t...

Embodiment 2

[0026] see figure 1 , the production method of water-milled glutinous rice flour of this embodiment is different from Embodiment 1 in that: in the pretreatment process (including cleaning, rinsing and soaking processes), the rinsing process adopts an automatic rinsing device, and the number of washings is 1 to 3 times. The temperature is controlled at 35-45°C, the soaking time is 1-2 hours, and the ratio of solid to liquid is 1:0.6-1.2.

Embodiment 3

[0028] see figure 1 , the production method of water-milled glutinous rice flour in this embodiment is different from that in Embodiment 1: in the pretreatment process, an automatic rinsing device is used for rinsing, and the number of washings is 2 times; the soaking temperature control parameter of the soaking process is set to 40-45 ° C , The soaking time is controlled at 1.5-2 hours, and the ratio of solid to liquid is controlled at 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com