Flame-retardant modified silicone oil, and preparation method and application thereof

A modified silicon and flame-retardant technology, which is applied in the preparation of silicone oil, the application in textile production, and the field of flame-retardant modified silicone oil. It can solve the problems of flame retardancy and achieve excellent softness and flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

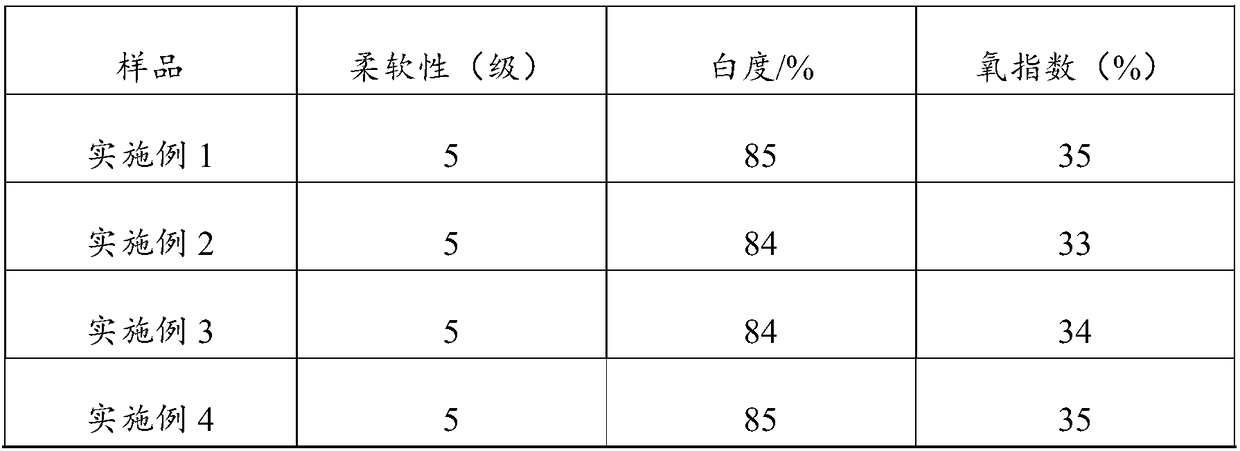

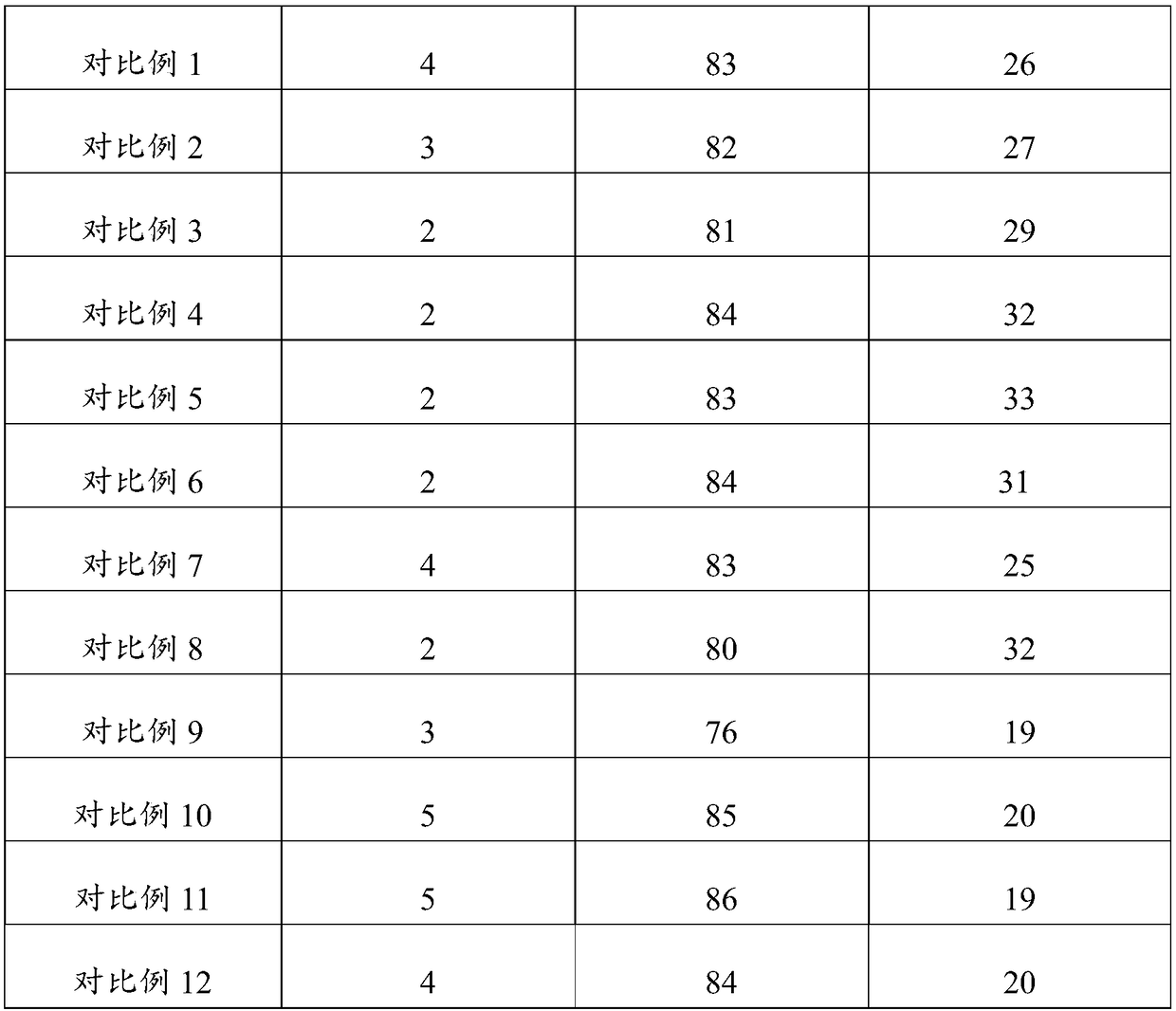

Examples

Embodiment 1

[0048] A flame-retardant modified silicone oil, prepared by the following method:

[0049] (1) prepare each raw material, the molar proportion of each raw material is:

[0050] Tetrabromophthalic anhydride diol 10mol%

[0051] Trimethylolmelamine resin 16mol%

[0052] 1,4-dibromo-2,3-butanediol 15mol%

[0053] Hexaethylcyclotrisiloxane 8mol%

[0054] Methyldichlorosilane 16mol%

[0055] 3-Aminopropylsilanetriol 15mol%

[0056] Ethylenediaminetetramethylenephosphonic acid 10mol%

[0057] Hexamethyldisiloxane 10mol%

[0058] The catalyst is phosphotungstic acid, and the dosage is 1% of the total molar weight of raw materials

[0059] Antioxidant is three (nonylphenol) phosphites, and consumption is 0.3% of material total molar weight

[0060] (2) Tetrabromophthalic anhydride diol, trimethylol melamine resin, 1,4-dibromo-2,3-butanediol, hexaethylcyclotrisiloxane, methyl dichlorosilane , 3-aminopropylsilanetriol and the catalyst were added to the reaction kettle, and the ...

Embodiment 2

[0065] A flame-retardant modified silicone oil, prepared by the following method:

[0066] (1) prepare each raw material, the molar proportion of each raw material is:

[0067] Tetrabromophthalic anhydride diol 18mol%

[0068] Trimethylolmelamine resin 15mol%

[0069] 1,4-dibromo-2,3-butanediol 14mol%

[0070] Hexaethylcyclotrisiloxane 9mol%

[0071] Methyldichlorosilane 14mol%

[0072] 3-Aminopropylsilanetriol 12mol%

[0073] Ethylenediaminetetramethylenephosphonic acid 9mol%

[0074] Hexamethyldisilazide 9mol%

[0075] The catalyst is phosphotungstic acid and the dosage is 1.5% of the total molar weight of raw materials

[0076] Antioxidant is three (nonylphenol) phosphites, and consumption is 0.3% of material total molar weight

[0077] (2) Tetrabromophthalic anhydride diol, trimethylolmelamine resin, 1,4-dibromo-2,3-butanediol, hexaethylcyclotrisiloxane, methyldichlorosilane, Add 3-aminopropylsilanetriol and catalyst into the reactor, and carry out polymerization ...

Embodiment 3

[0082] A flame-retardant modified silicone oil, prepared by the following method:

[0083] (1) prepare each raw material, the molar proportion of each raw material is:

[0084] Tetrabromophthalic anhydride diol 15mol%

[0085] Trimethylolmelamine resin 12mol%

[0086] 1,4-dibromo-2,3-butanediol 18mol%

[0087] Hexaethylcyclotrisiloxane 6mol%

[0088] Methyldichlorosilane 18mol%

[0089] 3-Aminopropylsilanetriol 13mol%

[0090] Ethylenediaminetetramethylenephosphonic acid 8mol%

[0091] Hexamethyldisiloxane 10mol%

[0092] The catalyst is phosphotungstic acid and the dosage is 0.5% of the total molar weight of raw materials

[0093] Antioxidant is three (nonylphenol) phosphites, and consumption is 0.2% of material total molar weight

[0094] (2) Tetrabromophthalic anhydride diol, trimethylolmelamine resin, 1,4-dibromo-2,3-butanediol, hexaethylcyclotrisiloxane, methyldichlorosilane, Add 3-aminopropylsilanetriol and catalyst into the reactor, and carry out polymerization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com