Soft nonwoven master batch and preparation method thereof

A technology of soft masterbatch and non-woven fabric, which is applied in the direction of rayon manufacturing, textile and paper making, single-component polyolefin artificial filament, etc. It can solve the problem of uncontrollable effect, low softness of soft masterbatch, and non-woven fabric Long time and other problems, to achieve a good soft effect, excellent softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

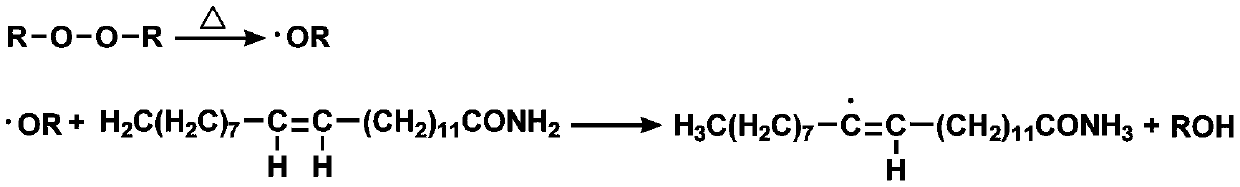

Method used

Image

Examples

Embodiment 1

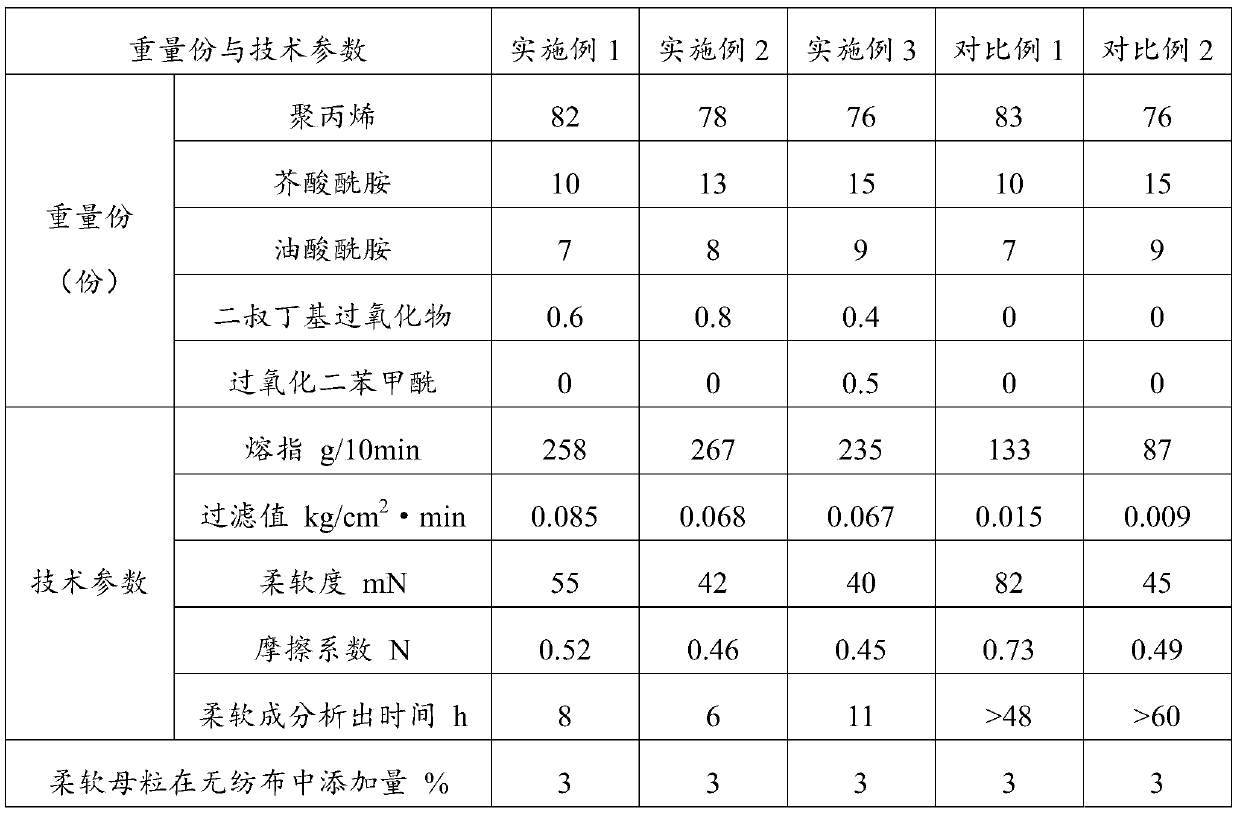

[0025] The soft non-woven masterbatch of the present embodiment has the following components by weight: 82 parts of polypropylene resin, 10 parts of erucamide, 7 parts of oleic acid amide, and 0.6 part of di-tert-butyl peroxide.

[0026] The preparation method of the soft non-woven masterbatch of this embodiment is as follows: firstly, heat and mix erucamide powder and di-tert-butyl peroxide in a high-speed mixer at a speed of 1000 revolutions / min at a temperature of 70°C for a period of time for 5min. Then, the activated erucamide, oleic acid amide, and polypropylene resin were melt-extruded in a co-rotating twin-screw extruder, wherein the rotational speed of the host machine was 380 Hz, and the rotational speed of the feeder was 410 Hz. Finally, water-cooled pelletizing is carried out.

[0027] The soft masterbatch prepared in this embodiment has a filtration value of 0.085kg / cm 2 ·min, melt index 258g / 10min, the softness of the non-woven fabric prepared by using this sof...

Embodiment 2

[0029] The soft non-woven masterbatch of the present embodiment has the following components by weight: 78 parts of polypropylene resin, 13 parts of erucamide, 8 parts of oleic acid amide, and 0.8 part of di-tert-butyl peroxide.

[0030] The preparation method of the soft non-woven masterbatch of this embodiment is as follows: firstly, heat and mix erucamide powder and di-tert-butyl peroxide in a high-speed mixer at a speed of 1100 revolutions / min at a temperature of 75°C for a period of time for 5min. Then, the activated erucamide, oleic acid amide, and polypropylene resin were melt-extruded in a co-rotating twin-screw extruder, wherein the rotational speed of the host machine was 360 Hz, and the rotational speed of the feeder was 420 Hz. Finally, water-cooled pelletizing is carried out.

[0031] The soft masterbatch prepared in this embodiment has a filtration value of 0.068kg / cm 2 ·min, melt index 267g / 10min The softness of the non-woven fabric prepared by using this soft...

Embodiment 3

[0033] The non-woven soft masterbatch of this embodiment, its components are calculated by weight: 76 parts of polypropylene resin, 15 parts of erucamide, 9 parts of oleic acid amide, 0.4 part of di-tert-butyl peroxide, peroxide 0.5 parts of dibenzoyl.

[0034] The preparation method of the soft non-woven masterbatch of this embodiment is as follows: first, heat and mix erucamide powder, di-tert-butyl peroxide and dibenzoyl peroxide in a high-speed mixer at a speed of 1100 rpm , the temperature is 75°C, and the time is 5min. Then, the activated erucamide, oleic acid amide, and polypropylene resin were melt-extruded in a co-rotating twin-screw extruder, wherein the rotational speed of the host machine was 420 Hz, and the rotational speed of the feeder was 410 Hz. Finally, water-cooled pelletizing is carried out.

[0035] The soft masterbatch prepared in this embodiment has a filtration value of 0.067kg / cm 2 ·min, melt index 235g / 10min, the softness of the non-woven fabric pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softness | aaaaa | aaaaa |

| Friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com