Patents

Literature

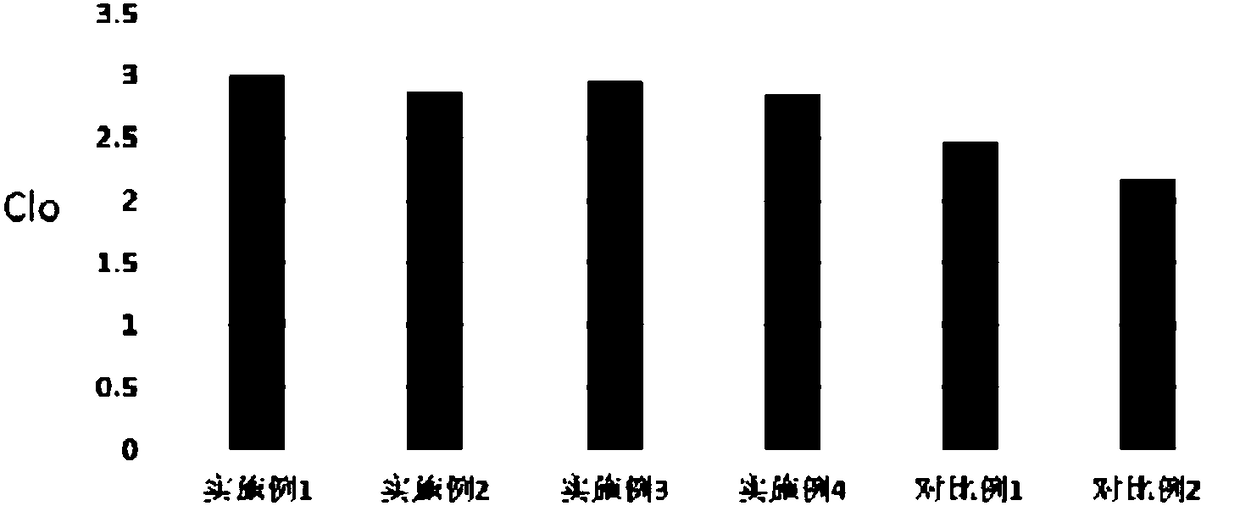

50results about How to "Fluffiness is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing technology for far-infrared polyester short fibers

InactiveCN102560732ALow costPromote environmental protectionHollow filament manufactureArtificial filament heat treatmentPolyesterManufacturing technology

The invention discloses a manufacturing technology for far-infrared polyester short fibers, which takes recycled PET (Polyethylene Terephthalate) as a raw material, and the recycled PET is processed sequentially through pretreatment, rotating drum drying, melt spinning, cooling formation, winding, drawing, curling, oil application, cutting and heat setting, so as to obtain finished products, wherein in the rotating drum drying step, the recycled PET is dried for 5.5 to 6.5 hours firstly, then far-infrared master batches are added, the final mass fraction of the far-infrared master batches ranges from 5 to 7 percent, the total drying time ranges from 9.5 to 10.5 hours, and far-infrared ceramic powders account for 19 to 21 percent in the far-infrared master batches; in the melt spinning step, the temperatures of a screw bolt and a spinning box body of a screw bolt extruder range from 268 to 278 DEG C, and cooling formation is carried out through circular air blow; in addition, the total drawing ratio is 3.0 to 3.5, the heat setting temperature ranges from 162 to 168 DEG C, and the heat setting time ranges from 8 to 12 minutes. The manufacturing technology can save cost and is beneficial to environmental protection, and the prepared finished products achieve good warmth retention and health protection properties.

Owner:HANGZHOU BEST CHEM FIBER

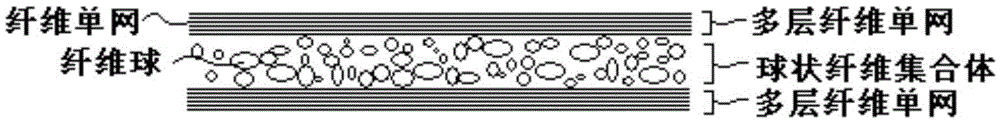

Heat preservation flocculus material, preparing method of heat preservation flocculus material and heat preservation product

InactiveCN105463697AFluffiness is goodGood compression resiliencePillowsSleeping rugSingle fiberMaterials science

The invention provides a heat preservation flocculus material, a preparing method of the heat preservation flocculus material and a heat preservation product, and belongs to the technical field of heat preservation flocculus materials. The heat preservation flocculus material comprises a plurality of stacked single fiber nets and spherical fiber assemblies at least distributed between part of the adjacent single fiber nets. The heat preservation flocculus material has the excellent comprehensive performance such as filling power, compression rebound resilience, heat preservation performance and washing resistance.

Owner:3M INNOVATIVE PROPERTIES CO

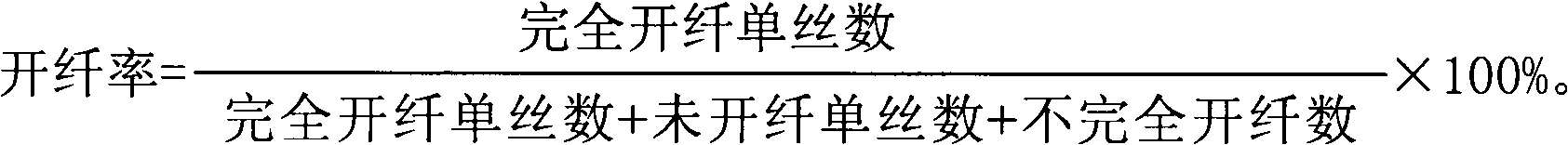

High-density microfiber wiping cloth and processing method thereof

InactiveCN103126625AHigh liquid absorption and retention rateFluffiness is goodCarpet cleanersFibre typesPolyesterMicrofiber

The invention discloses a high-density microfiber wiping cloth and a processing method thereof. The wiping cloth contains polyester and nylon composite filament, the splitting rate of which is more than 80% and filament number of which is from 0.01 dtex to 0.6 dtex, and the polyester and nylon composite filament is 20%-100% of the wiping cloth in weight. According to JIS1096826IA, the ventilation capacity of the wiping cloth is less than 50cm3 / cm2 / sec. The wiping cloth has the advantages of comfortable feeling, density, high fluid suction and fluid keeping, no harm to surface and high wiping performance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

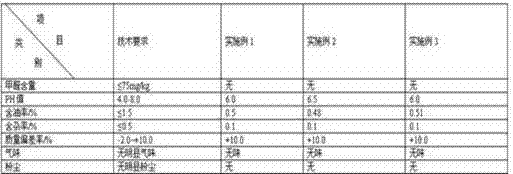

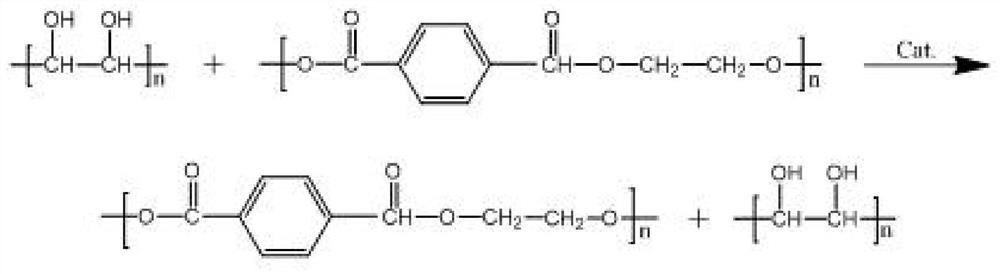

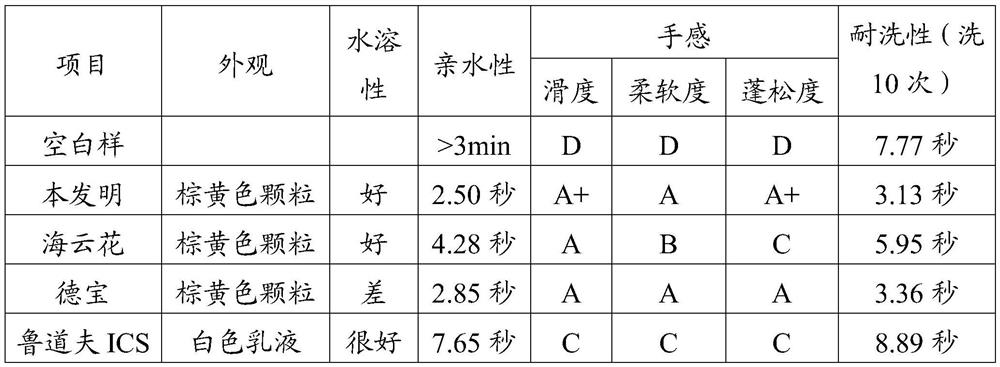

Hydrophilic fabric softener

The invention discloses a hydrophilic fabric softener, which is prepared from the following components by weight: 20-30 parts of hydrophilic amino silicone oil, 12-20 parts of dodecylbenzene sulfonic acid, 15-36 parts of fatty alcohol-polyoxyethylene ether, 14-25 parts of amino modified polysiloxane, 21-32 parts of sodium tripolyphosphate, 5-18 parts of hydroxy methyl cellulose, 3-9 parts of acrylamide, and 100-150 parts of water. By the way, the hydrophilic fabric softener provided by the invention has smooth handfeel and good filling power, provides fabrics with good re-wettability and antistatic properties, provides textile fiber with good lubricating properties, and improves the tear and friction properties.

Owner:无锡市华誉日用品厂

Preparation method of fine dry silk product

InactiveCN106894099AFluffiness is goodEliminate chemical residuesAnimal materialSilk filament obtainingMoistureImpurity

The invention discloses a method for preparing silk fine dried product, which comprises the following steps: primary soaking, primary dehydration, foaming, secondary soaking, second and third dehydration, bleaching, fourth dehydration, reduction, tank washing and five dehydration, wetting, After six times of dehydration, fluffing, drying, awakening, and multiple rinsing, the dry product has a lower impurity rate and improves the quality of the entire product.

Owner:JIANGSU SPCC SILK

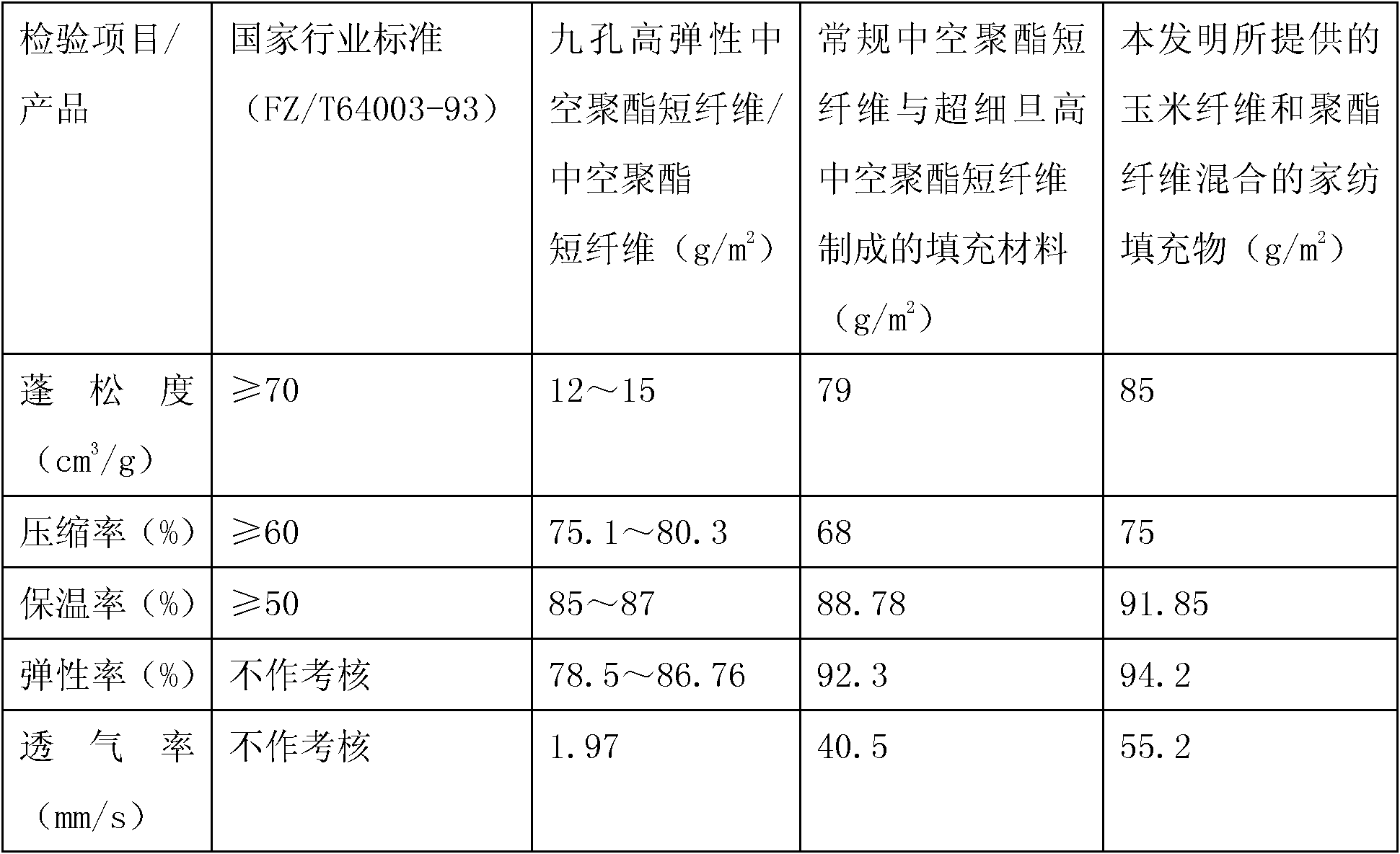

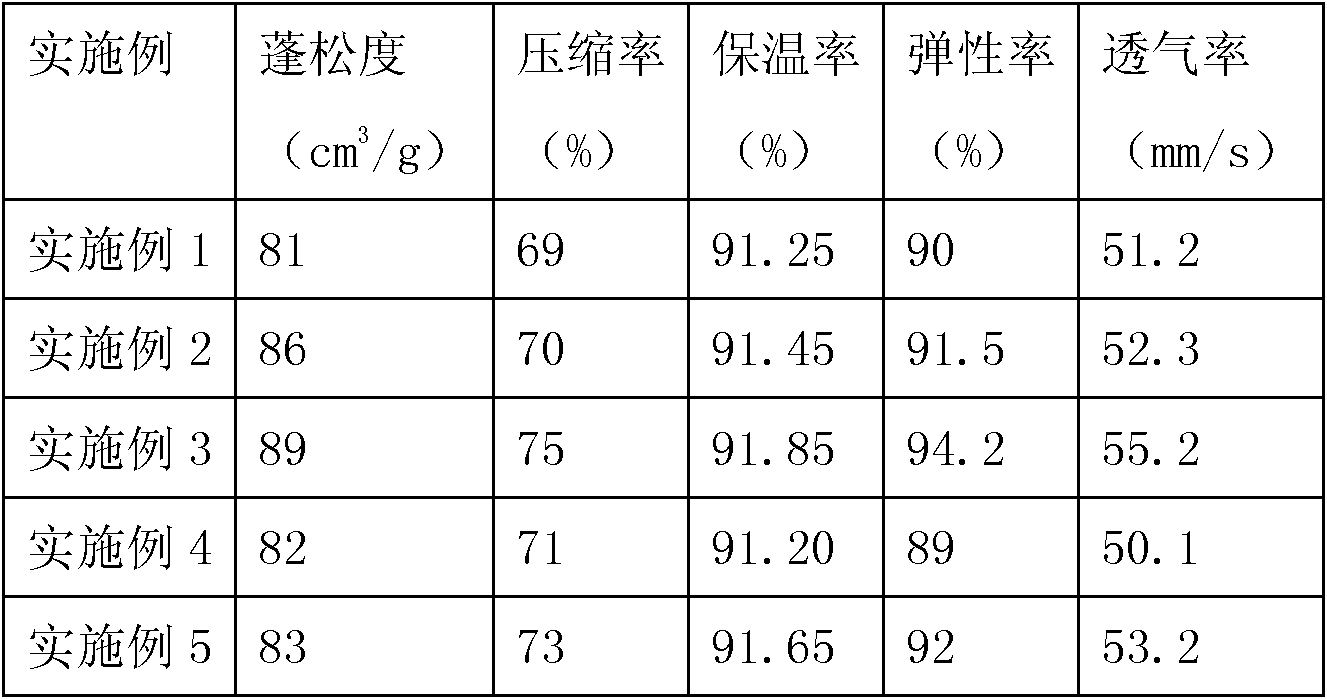

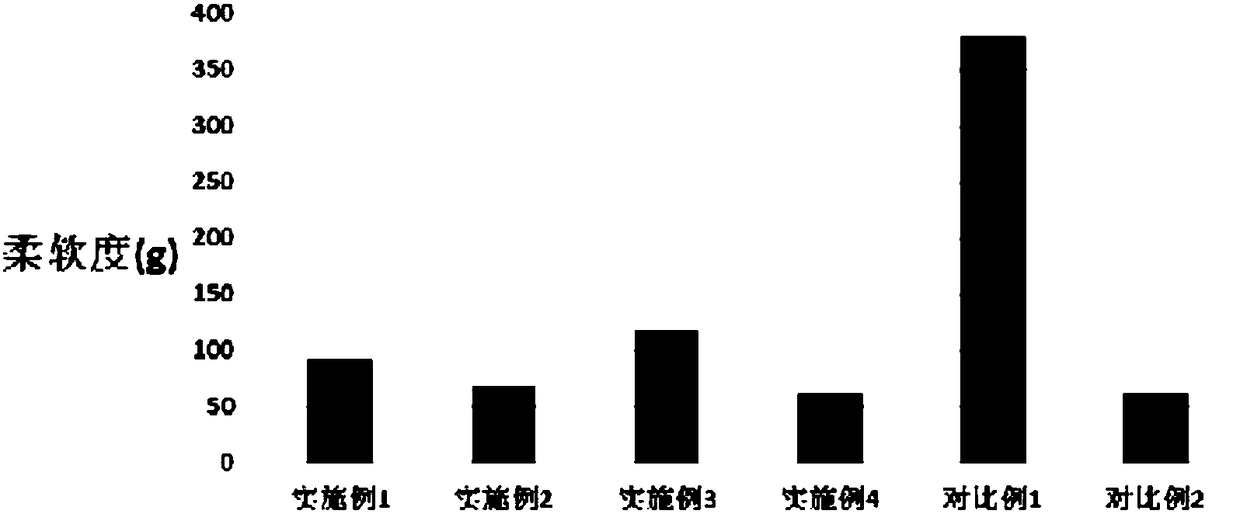

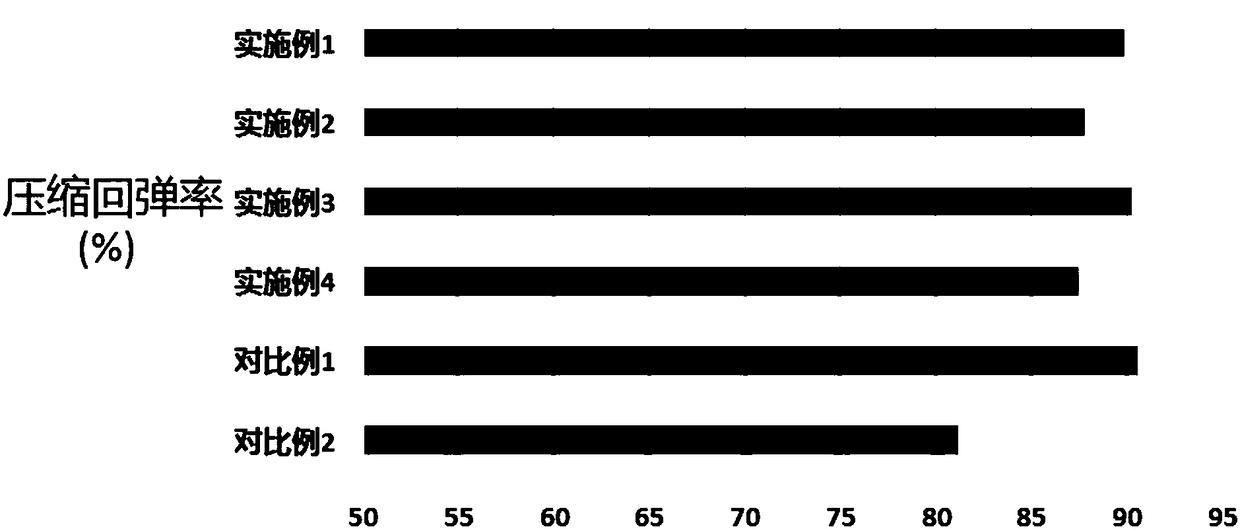

Textile filler formed by mixing corn fibers and polyester fibers and preparation method thereof

InactiveCN103030091ASolve the problem that it is difficult to form a cotton webWell mixedUpholstery manufactureUpholstery fillingPolyesterQuality of life

The invention discloses a textile filler formed by mixing corn fibers and polyester fibers, which is characterized in that the textile filler is formed by mixing conventional hollow polyester staple fibers and corn fibers, and the hollow polyester staple fiber has a fineness of 6. 67DTEX, a hollow degree of 10%, and a length of 38mm; the corn fiber has a fineness of 1.5 to 3.0 dtex, and is a crimped fiber with a length of 50 to 90mm, and the weight percentage of the hollow polyester staple fibers is 25% to 75%; and the weight percentage of the corn fiber is 25% to 75%. The invention also provides a preparation method of the textile filler formed by mixing the corn fibers and the polyester fibers. Various filler products prepared by the textile filler formed by mixing corn fibers and polyester fibers have the advantages of uniform and smooth appearance, lightweight sense, higher filling power, lasting elastic restoring force, excellent warmth and soft hand feel, and makes people feel comfortable, thereby improving sleep and quality of life.

Owner:SOUTH BEDDING TECH

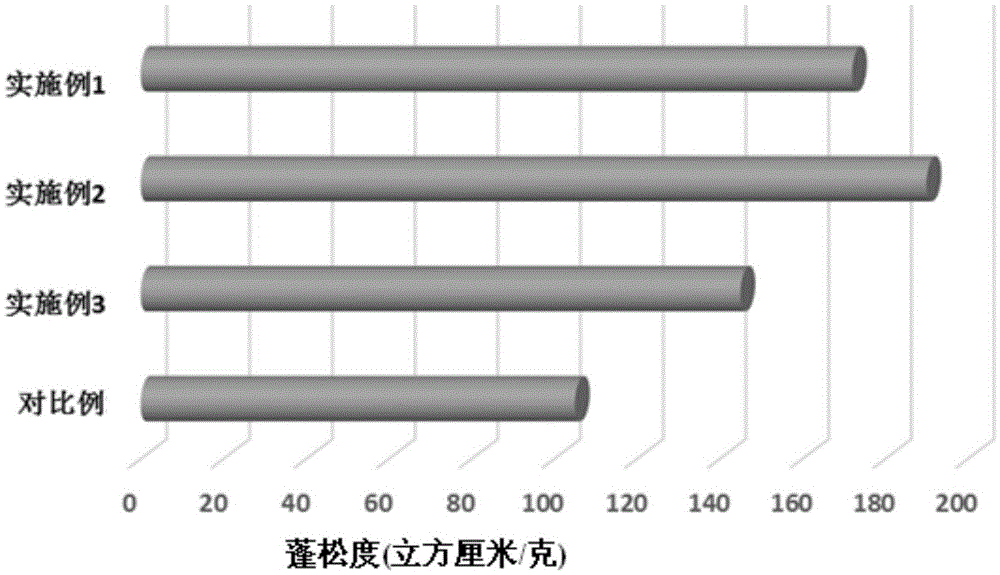

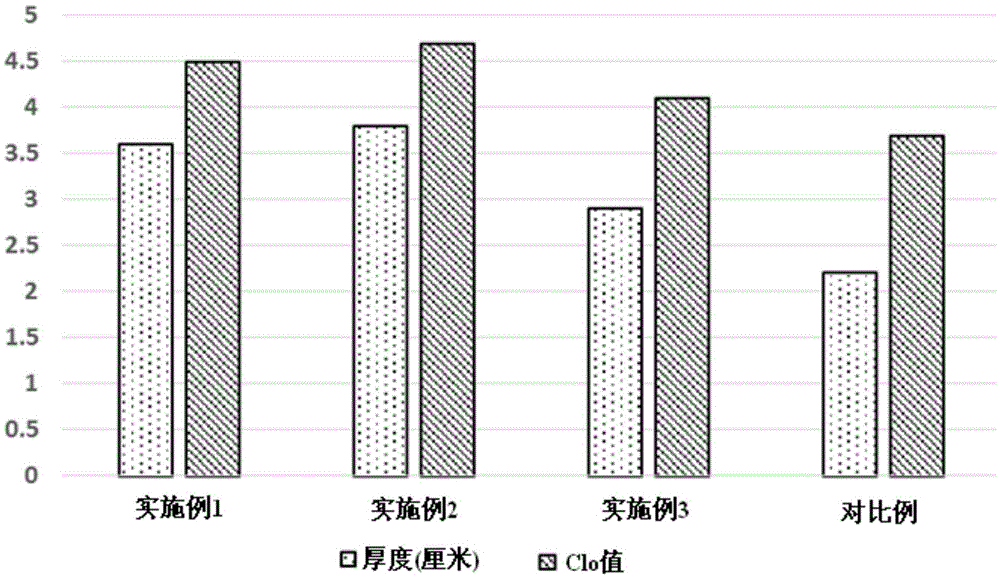

Insulation flaked material and preparation method and insulation product thereof

InactiveCN108085869AGood flexibilityIncrease elasticityNon-woven fabricsAdhesivesCellulose fiberElastic fiber

The invention provides an insulation flaked material and a preparation method and an insulation product thereof, and belongs to the technical field of insulation flaked materials, the problem at leastcan be partially solved that the existing insulation flaked material is difficult to obtain good softness, resilience, filling power and heat retaining property simultaneously. The insulation flakedmaterial comprises a multilayered and heat-set fiber single-net, wherein each layer of fiber single-net is prepared from, by weight, 10-50% of cellulose fiber, 5-25% of low-melting elastic fiber, and25-85% first class fiber, wherein the cellulose fiber which does not belong to the low-melting elastic fiber, the low-melting elastic fiber which does not belong to the cellulose fiber, and the firstclass fiber which does not belong to the cellulose fiber and also does not belong to the low-melting elastic fiber.

Owner:3M CHINA

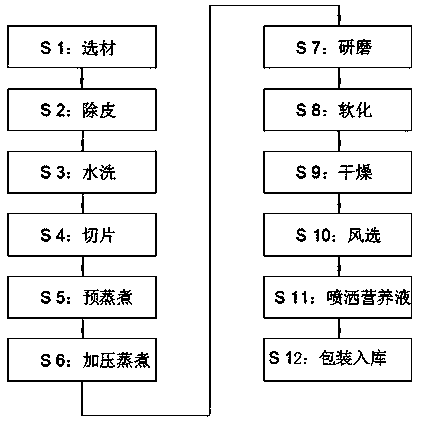

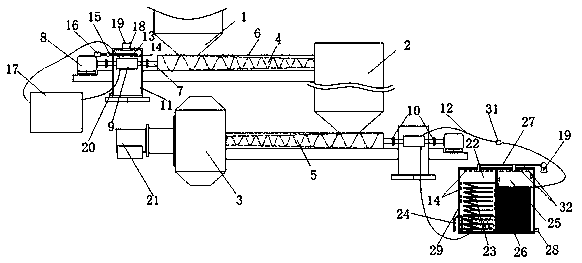

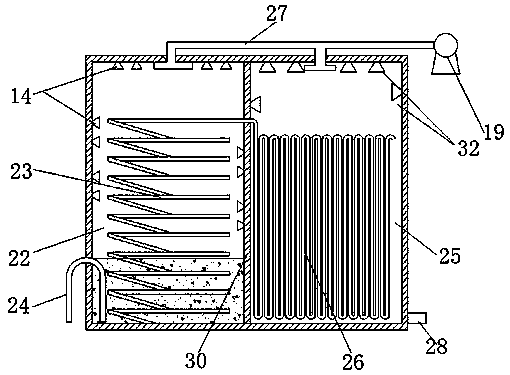

Wood fiber production method

ActiveCN110195372AImprove water absorptionImprove water retentionPretreatment with water/steamImpregnation spraying apparatusWood fibreNutrient solution

The invention discloses a wood fiber production method, which comprises: S1, material selection; S2, skin removal; S3, water washing; S4, slicing; S5, pre-cooking; S6, pressurizing cooking; S7, grinding; S8, softening; S9, drying; S10, air selection; S11, nutrient solution spraying; and S12, packaging warehousing. According to the present invention, the wood fiber produced through material selection, skin removal, water washing, slicing, pre-cooking, pressurizing cooking, grinding, softening, drying, air selection, nutrient solution spraying, packaging warehousing and other steps can be well used in spray seeding technologies; the wood fiber produced by the method has good softness; and during the spray seeding, when the wood fiber, the water and the binder are mixed, the wood fiber has good water absorption, such that each wood fiber can absorb a large amount of water so as to achieve good water content.

Owner:东南生态修复有限公司

Fabric containing hollow fiber and production method thereof

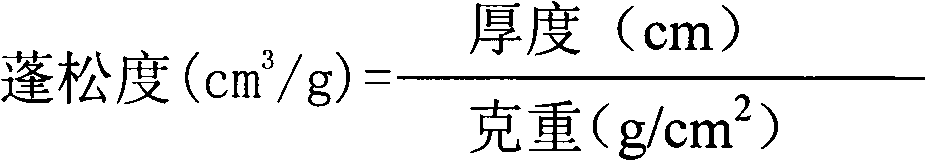

ActiveCN104233604AOvercoming false twist processing or twisting destroys hollownessSuperior LoftWeft knittingYarnEngineering

The invention discloses a fabric containing hollow fiber and a production method thereof. The fabric containing hollow fiber is a knitted fabric formed by at least hollow cation dyeable false twisted yarn or staple fiber yarn and spandex fiber. Tested according to the JISL1096:2010 standard, the fabric obtains a filling power more than 4.0 cm3 / g and a gram weight higher than 150-250 g / m2; the hollow area of more than 80% of the filaments of the hollow cation dyeable false twisted yarn or staple fiber yarn is 50-150 mm2. Knitted from the hollow cation dyeable false twisted yarn or staple fiber yarn with restorable degree of hollowness, the fabric containing the hollow fiber ensures the elasticity, light weight and soft hand feeling.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Compound forming method of multi-layered knitted fabric made of multi-component raw materials

InactiveCN102719980ASolution to short lifeIncrease elasticityWeft knittingLayered productsChemical compositionEngineering

The invention discloses a compound forming method of a multi-layered knitted fabric made of multi-component raw materials, wherein multiple raw materials are adopted to knit on a two-layered weft-knitting circular knitting machine, by changing the arrangement method of upper disc knitting needles and lower drum needles, the triangles knitted by the upper disc and the triangles knitted by the lower drum are arranged to form different upper and lower structures, and the upper and the lower layers can be compounded through the tucking knitting of the upper and the lower knitting needles. By adopting the same or different raw materials and the knitting method, the upper and the lower layers, namely front and back sides of the fabric and the lining materials are compounded, as a result, the fabric has the advantages that the production procedure is simple, no chemical component exists within, the elasticity is excellent, and the fill power is very high; furthermore, the two layers of the compound fabric can adopt different raw materials and different structures, so as to form different appearances and possess different styles and functions.

Owner:SICHUAN TEXTILE SCI RES INST

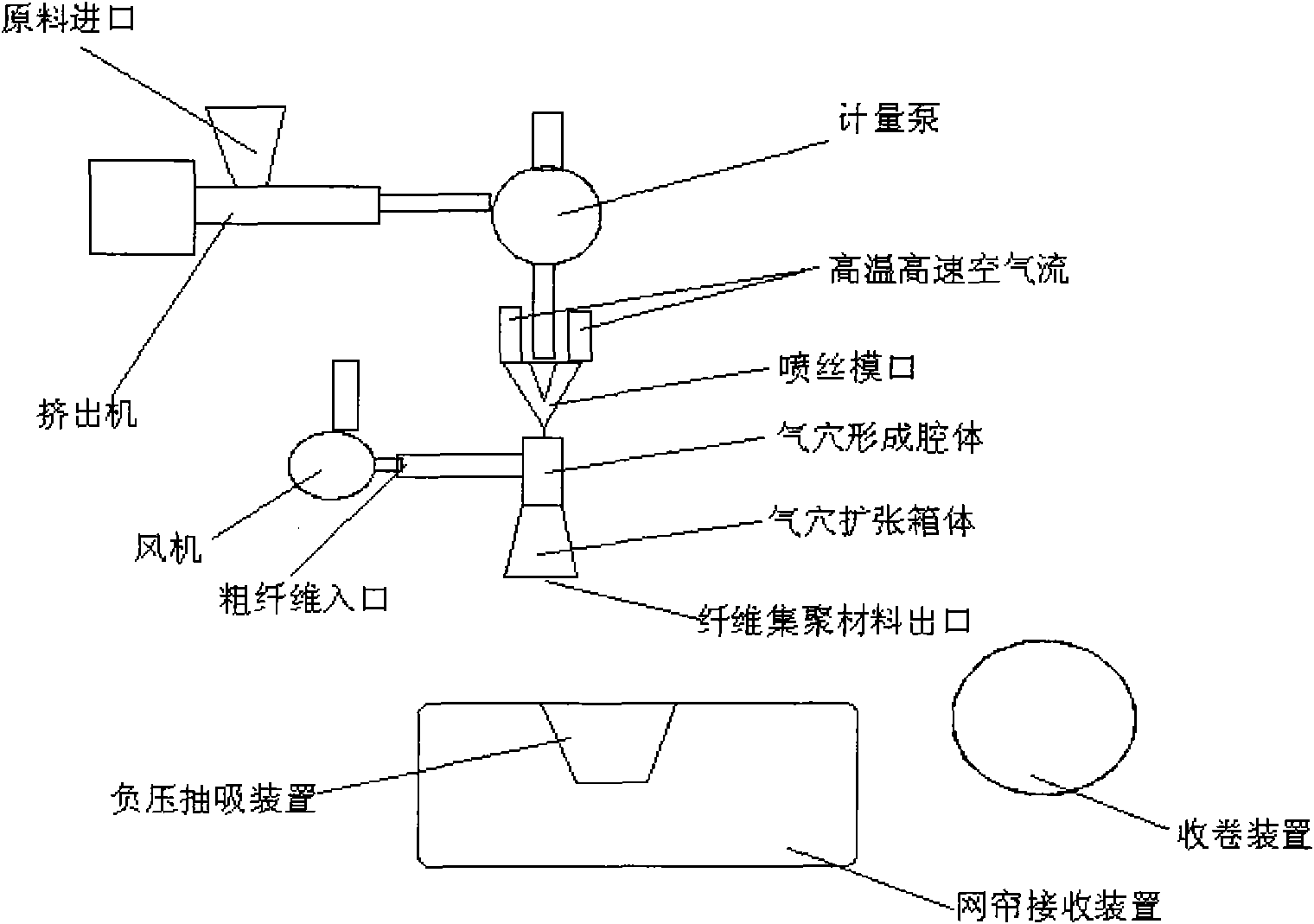

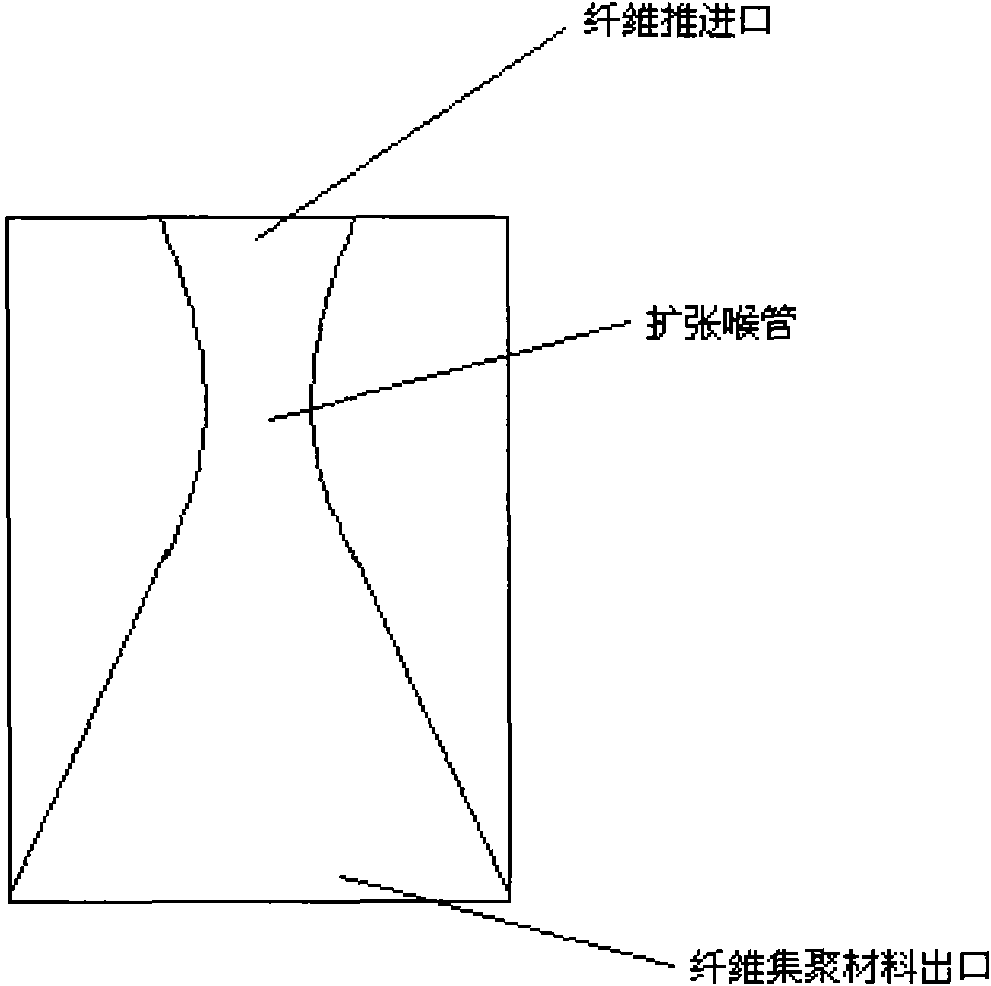

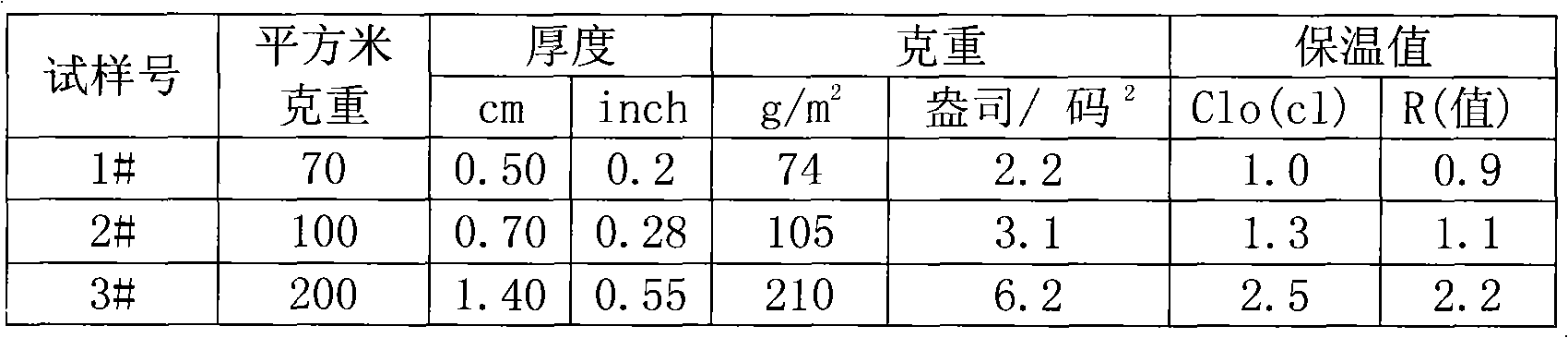

Fiber aggregate material formed by coating fine air pockets by microfibers and production process thereof

ActiveCN101892527AGood compressibilityFluffiness is goodFilament manufactureTextile/flexible product manufactureThermal insulationMicrofiber

The invention discloses a fiber aggregate material formed by coating fine air pockets by microfibers, which is a novel fibrous material that two components microfibers and coarse fibers are symbiotic. The invention also discloses a production process for the fiber aggregate material, which comprises the following steps of: making a raw material pass through a spinning die orifice for direct melting spinning, and coating the molten polyolefine microfibers on the peripheries of polyester coarse fibers with the shape memory function, wherein the shape memory coarse fibers are used as a carrier for forming the air pockets; quickly cooling to normal temperature and curing; and finally, forming the microfiber aggregate material with irregular air pockets. The material can be used for making thermal materials of ski shirts, field tents, military battle-dress uniforms, thermal equipment for field camping of soldiers, sleeping bags, climbing clothes, thermal underwear, gloves and shoes, and is also used for making various sound-absorbing thermal insulation automobile interior materials and the like.

Owner:JIANGSU LIYANG NEW MATERIALS CO LTD

Fluffy and soft skin-friendly medical non-woven fabric and preparation method thereof

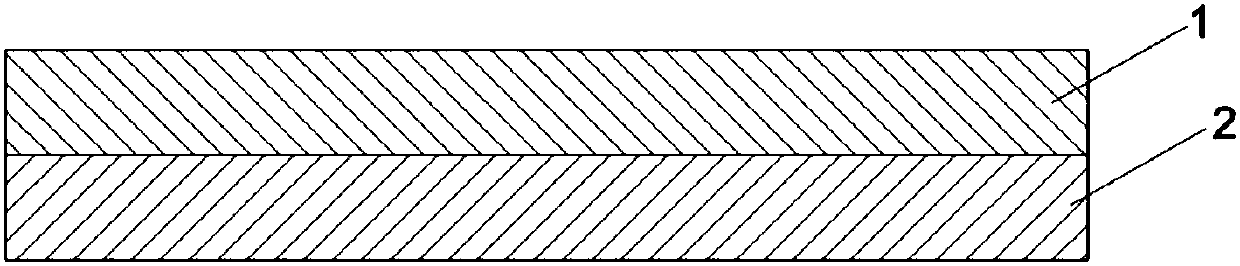

InactiveCN111321521ALarge distributionImprove bulkFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a fluffy and soft skin-friendly medical non-woven fabric and a preparation method thereof. PP and PE are used as spinning raw materials and an elastic copolymer is mixed in theraw materials. The preparation method specifically comprises the following steps that two-component spunbond equipment is adopted for production, and fiber-grade spinning PP slices and spinning PE slices are taken as the spinning raw materials, wherein the PP is taken as a core layer and the PE is taken as a skin layer, the elastic copolymer is uniformly mixed, the PE layer with a lower melting point is melted to generate bonding in a hot rolled reinforcement process, and a melt passing through a spinning box body is distributed to form a double-component filament of a skin-core structure, and is cooled and stretched to form a net on a receiving device; the generated net is subjected to a hot rolling process, a specially designed hot roller is adopted, so that the PE on the surface layerof the net is melted, a bonding point is formed between fibers on the net, and then the net is consolidated to form the non-woven fabric; and the prepared non-woven fabric is subjected to a solvent after-finishing process, and the non-woven fabric is subjected to single-sided coating by adopting an antistatic agent.

Owner:浙江冠诚科技有限公司

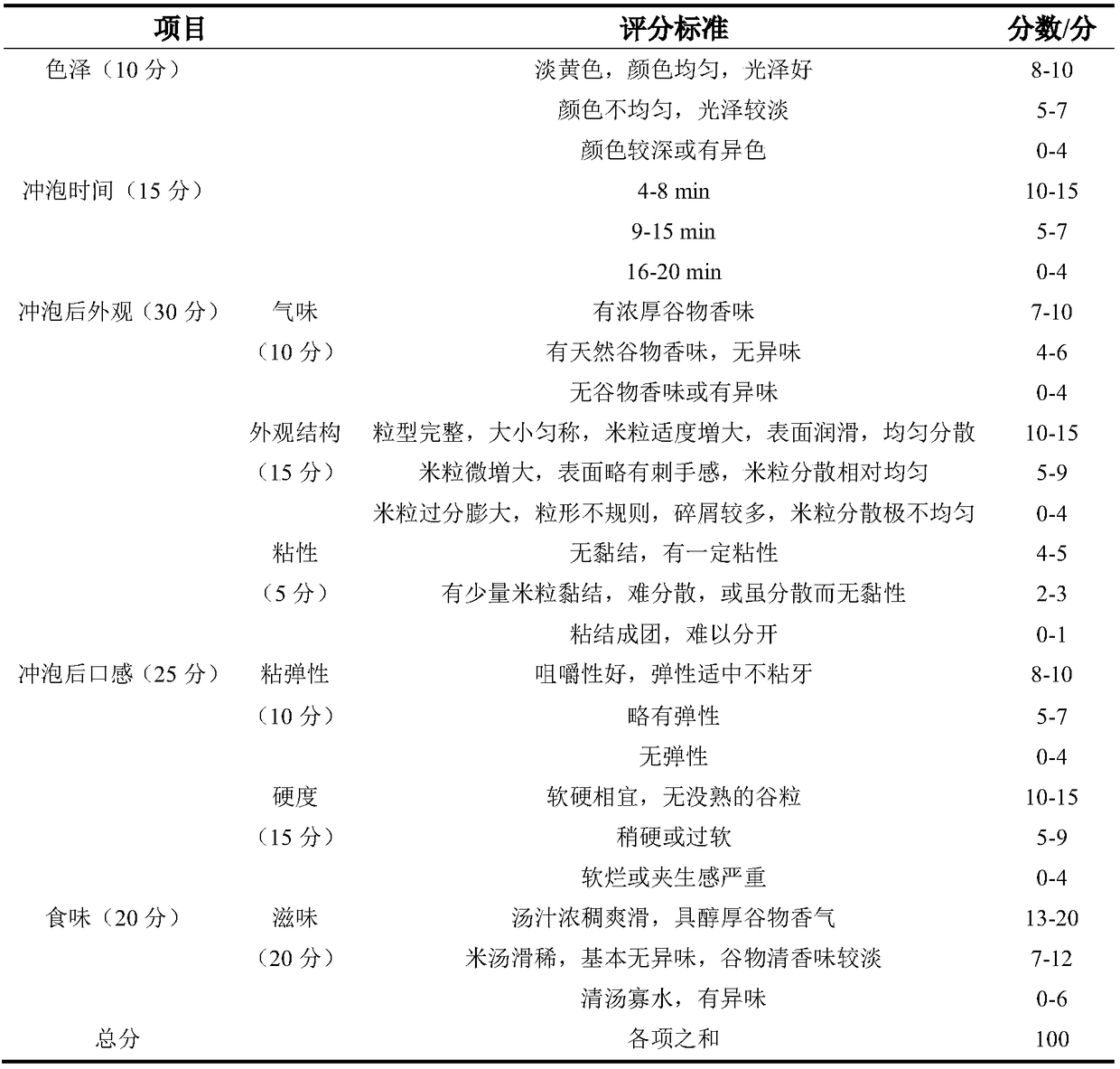

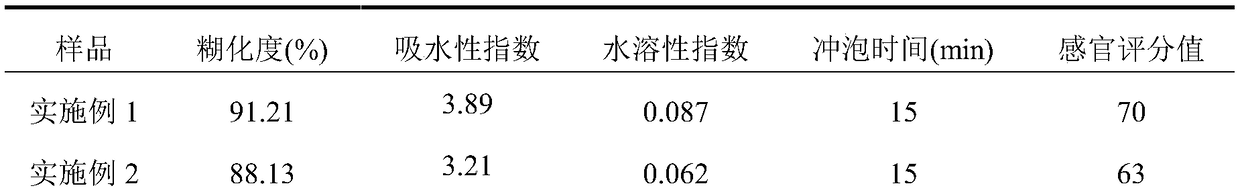

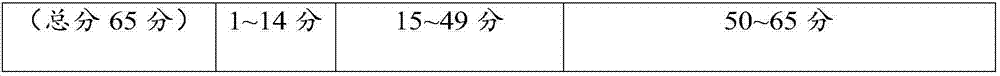

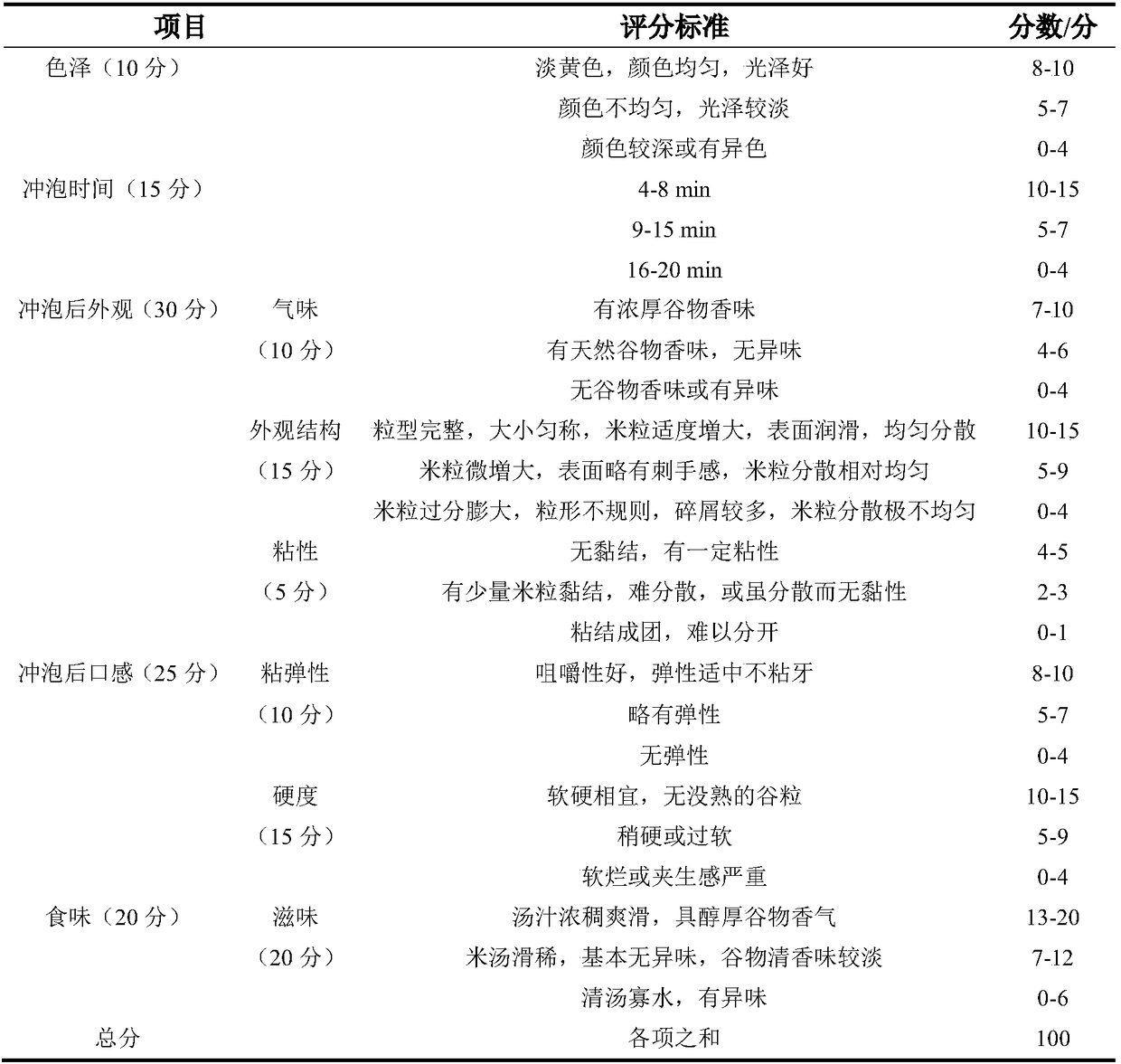

Ready-to-eat coarse food grain porridge made by light fermentation method

InactiveCN108719805AAvoid uneven ripeningFluffiness is goodYeast food ingredientsFood thermal treatmentReady to eatYeast

The invention relates to ready-to-eat coarse food grain porridge made by a light fermentation method, and belongs to the field of food processing. Through synergistic reaction of superheated steam puffing treatment, a yeast light fermentation technique, an extruding and curing technique and a microwave-hot blast tunnel type drying technique, the ready-to-eat coarse food grain porridge is made. Theready-to-eat coarse food grain porridge is mainly made through the main steps of pretreating raw materials, performing raw material pre-puffing, performing crushing, adding yeast, performing conditioning, performing extruding, performing cutting for shaping, performing drying and performing packing. Superheated steam is adopted to be used for prepuffing grains, the yeast light fermentation technique is used for achieving ideal looseness, the extruding technique is used for curing and shaping materials, the microwave-hot blast tunnel type drying technique is used for delaying product ageing, and through combined action of four techniques, the made coarse cereal rice grains can be eaten after being soaked for 4-5min with boiling water. Original strong fragrance and granule integrity of thegrains are basically reserved. The ready-to-eat coarse food grain porridge has good chewiness, and is free from addition of essence and pigment, and the sense organ and the mouth feel of the ready-to-eat coarse food grain porridge are similar to those of coarse food grain porridge boiled in families.

Owner:NANCHANG UNIV

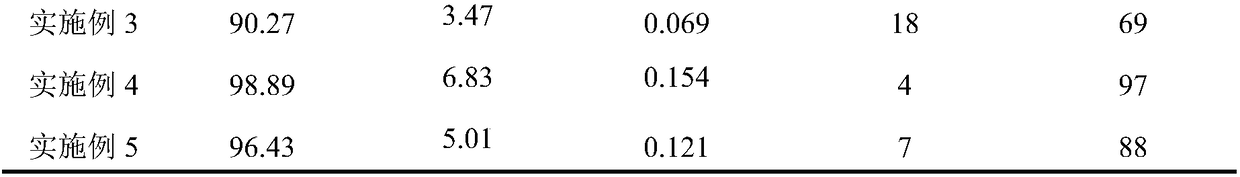

Multifunctional moisture absorption and sweat releasing finishing agent and preparation method therefor

ActiveCN111705511AStrong water absorptionGood moisture permeabilityGrip property fibresPolymer sciencePolyethylene terephthalate glycol

Owner:湖南金全立生物科技股份有限公司

Fabric as well as preparation processes and applications thereof

ActiveCN109594198AFluffiness is goodImprove loftNon-woven fabricsNonwoven fabricAgricultural machinery

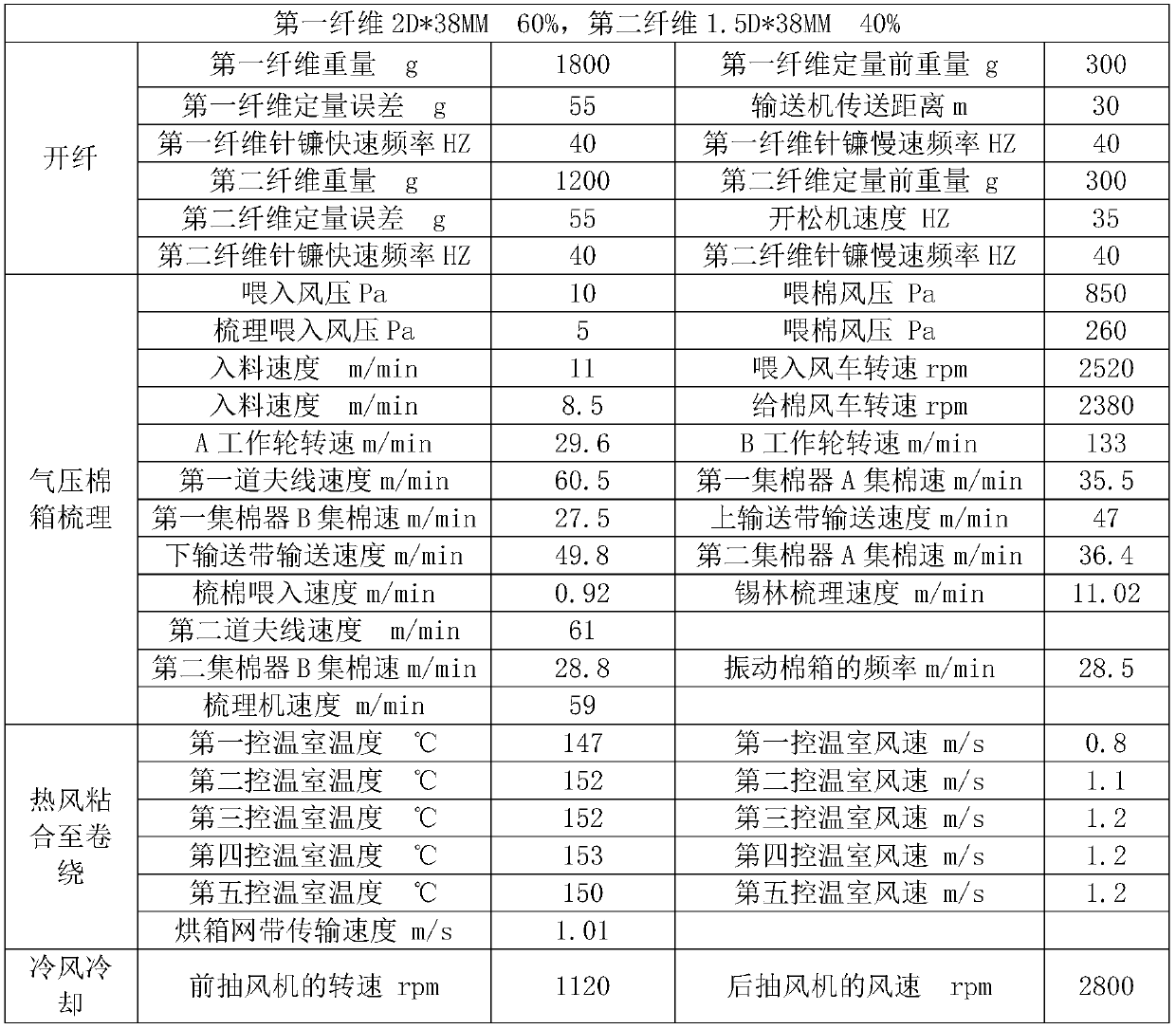

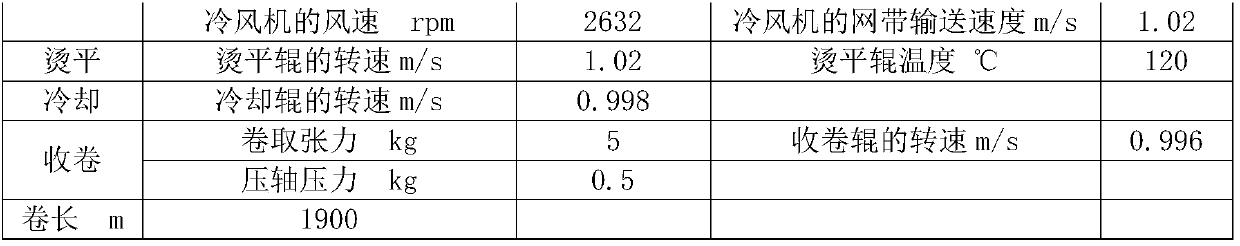

The invention provides fabric as well as preparation processes and applications thereof, and relates to the field of production of non-woven fabric. The fabric comprises first fibers with fiber fineness of 1.8-2 D and second fibers with fiber fineness of 1.5-1.8 D, and the weight ratio of the first fibers to the second fibers is 60%-70%:30%-40%. Fluffy fabric has excellent fluffiness and thicknesswithout pile, the preparation process of the fluffy fabric is also provided, and the fluffy fabric with excellent fluffiness can be prepared with the process. Water-repellent fabric and the preparation process of the water-repellent fabric are also provided, and the water-repellent fabric with excellent fluffiness can be prepared with the preparation process of the water-repellent fabric and is applied to damp-proofing of agricultural machinery and air-drying of crops.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Fragrant sterilizing-type pea-hull composite cat litter and preparation method thereof

InactiveCN106386525AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateLiving environment

The invention belongs to the technical field of a process for a cat litter, and specifically relates to a fragrant sterilizing-type pea-hull composite cat litter and a preparation method thereof. According to the invention, pea hulls are capable of emitting slightly sweet and fragrant smells in the process of processing, so the prepared cat litter by the invention has pea-hull fragrance, low density and good water absorptivity, bulkiness, antibacterial properties and adsorption properties, is biodegradable, green and environmentally friendly, and effectively improves the living environment of a cat; meanwhile, regularly-cleaned cat litter is poured into soil and can play the role of improving soil, and the regularly-cleaned cat litter contains animal manure, thereby being able to be used as an organic fertilizer, so resources are saved. The preparation method provided by the invention has the following advantages: through mutual compounding effects of the pea hulls with filled-type wood, an antibacterial agent, sodium bicarbonate and a binder, and by adopting a vertical-type ring die granulating machine, the prepared cat litter has uniform particle size, small pore size and good bulkiness; strong adsorption of the cat litter to manure odor is guaranteed; meanwhile, the yield is large; and production efficiency is improved.

Owner:YANTAI CHINA PET FOODS GRP

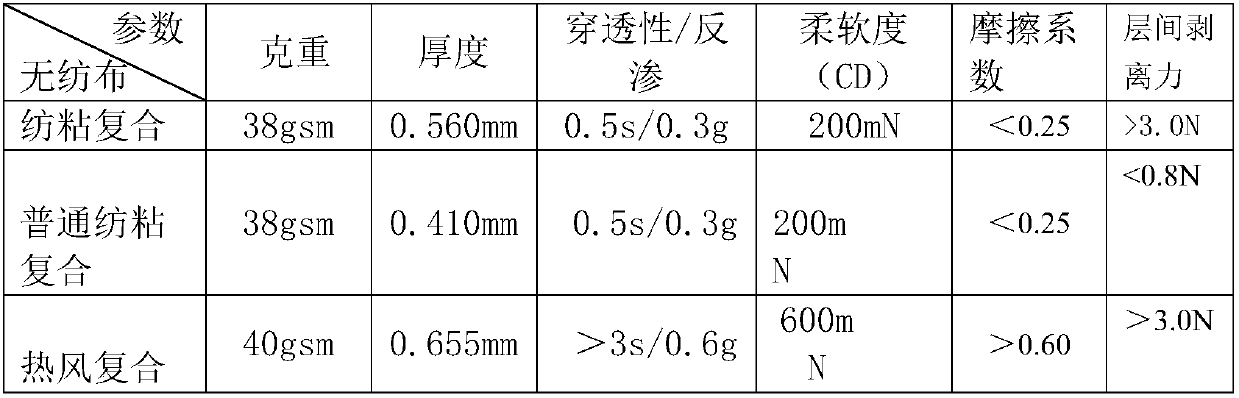

Spunbond two-component fiber non-woven fabric and processing equipment and technology thereof

InactiveCN107761253AFluffiness is goodGood softnessAbsorbent padsNon-woven fabricsWoven fabricSurface layer

The invention discloses a spun-bonded two-component fiber non-woven fabric, which comprises an upper layer and a lower layer, and the upper layer is composed of 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles passing through a screw extruder After extruding the two component products respectively, the surface layer structure of the surface layer PE with the "skin-core" structure is sprayed out through the two-component spinneret hole. The lower layer is composed of 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles are extruded through the screw extruder to extrude the two component products, and then sprayed out through the two-component spinneret. The surface layer structure and the bottom layer structure are embossed and heat-sealed by "bump-type" hot rolls. The invention has excellent bulkiness and softness, especially the interlayer peeling force, which can achieve the same effect as that of hot-air composite non-woven fabrics, and the spun-bonded penetrability and reverse osmosis performance are obviously better than hot-air products.

Owner:浙江欣富无纺布科技有限公司

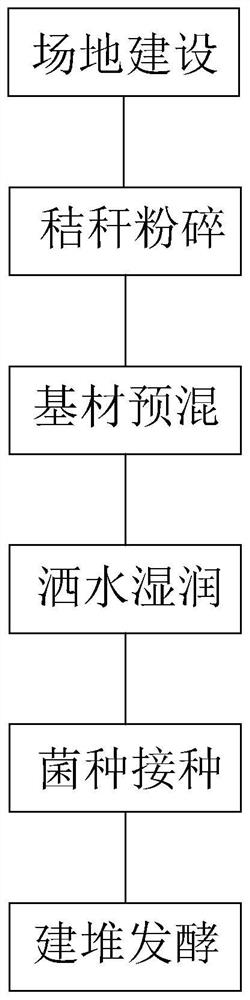

Agricultural solid waste composting method, fertilizer product and application of fertilizer product

PendingCN113307706AEffective fermentationUniform fermentationBio-organic fraction processingBioloigcal waste fertilisersAgricultural engineeringEnvironmental engineering

The invention relates to the technical field of agricultural solid waste recycling, in particular to an agricultural solid waste composting method, a fertilizer product and application of the fertilizer product. The composting method comprises the steps of site construction, straw smashing, base material premixing, watering and wetting, strain inoculation and pile construction and fermentation, composting can be completed in a short time to obtain a corresponding fertilizer product, and the composting product can effectively improve the soil aggregate structure and increase the soil fertility and has high application value.

Owner:上海为绿景观建设有限公司

Moisture-absorbing and quick-drying finishing agent for textiles and preparation method of finishing agent

ActiveCN113235301AGood sweat absorptionImprove quick-drying performanceGrip property fibresEpoxyPolymer science

The invention discloses a preparation method of a moisture-absorbing and quick-drying finishing agent for textiles. The preparation method comprises the following steps of (1) reacting allyl alcohol polyether with hydrogen-containing silicone oil to prepare an intermediate A; (2) reacting allyl epoxy polyether with hydrogen-containing silicone oil to prepare an intermediate B; (3) reacting the intermediate B with polyether amine ED2003 to obtain an intermediate C; and (4) mixing and uniformly stirring ethylene oxide-propylene oxide copolyether, an octadecyl tertiary amine aqueous solution, a polyurethane aqueous solution, water, the intermediate A and the intermediate C to obtain the moisture-absorbing and quick-drying finishing agent for the textiles. The finishing agent prepared by the method is used for after-finishing of the textiles, so that the textiles have excellent sweat-absorbing and quick-drying effects, are good in hand feeling and have excellent bulkiness, softness and rebound resilience. The invention also provides the moisture-absorbing and quick-drying finishing agent for the textiles prepared by the method.

Owner:广东宏昊化工有限公司

Aromatic sterilization type birch compound cat litter and preparation method thereof

InactiveCN106332791AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateFeces

The invention belongs to the technical field of cat litter process, and in particular relates to aromatic sterilization type birch compound cat litter and a preparation method thereof. In a processing process, birch emits a slight fragrant and sweet smell; the cat litter prepared by the method has the fragrance of the birch, is low in density, has good water absorption, bulkiness, antibacterial property and adsorption property, is biodegradable, green and environmental-friendly, and can effectively improve the living environment of cats; the regularly cleaned cat litter can play a role in improving the soil after being put into the soil, and can be used as organic fertilizer so as to save resources due to containing animal feces. According to the preparation method provided by the invention, the birch is compounded with filling type wood, an antibacterial agent, sodium hydrogen carbonate and a binding agent for realizing a synergistic effect; a vertical ring die granulator is adopted, so that the prepared cat litter is uniform in particle size, tiny in aperture and good in bulkiness, and the strong absorption of the cat litter for the odor of the feces is guaranteed; furthermore, the yield is high, and the production efficiency is increased.

Owner:YANTAI CHINA PET FOODS GRP

Untwisted yarn and twisted yarn combination fabric

The invention discloses a mixing fabric of untwisted yarn and twisted yarn, comprising warp and weft. The warp and the weft are twisted yarn or untwisted yarn, and the twisted yarn and the untwisted yarn are crossly arranged; the fibers of the untwisted yarn are arranged in parallel and are straight line shape. The fabric surface formed by cross arrangement of the twisted yarn and the untwisted yarn is provided with blocks, and the fabric density is 600 to 800 yarn / 10 cm. The invention has the advantages of good fabric three-dimension effect, comparatively higher tensile resistance strength, fine molding ability, and softness, bulkiness, permeability and moisture absorption that are all superior to all existing fabrics, light weight, smooth surface, good thermal preservation, comparatively stronger skin affinity and lower manufacturing cost, furthermore, the invention has better three-dimension, better impressions and good comfort characteristic, and the invention can be applied to the production of clothes or bedding, etc.

Owner:马玉成

Method for making freeze-dried okra and freeze-dried okra

InactiveCN107334105AExtended shelf lifeCrispy tasteFood freezingFood dryingFreeze-dryingExpiration date

The invention discloses a method for making freeze-dried okra, and belongs to the field of healthcare food. The method comprises the following steps: performing freeze-drying on a first okra by using a vacuum freeze-drying method so as to obtain a first freeze-dried okra; crushing and squeezing a second okra so as to obtain okra juice and a crushed okra material; performing freeze-drying and crushing on the crushed okra material by using the vacuum freeze-drying method so as to obtain a second freeze-dried okra; uniformly mixing the second freeze-dried okra with the okra juice, coating the surface of the first freeze-dried okra, and drying at a temperature of 0-5 DEG C, so as to obtain the freeze-dried okra, wherein the mass ratio of the first freeze-dried okra to the second freeze-dried okra is 10 to 20-30. The method is simple and applicable to industrial production, the expiration date of the okra can be delayed, nutrient components of okra are maintained, and original colors and taste of the okra are maintained. The freeze-dried okra made by using the method is long in preservation time, complete in nutrition maintenance, original in color and taste, good in healthcare function, soft in outer layer, crispy in inner layer and good in taste.

Owner:贵州蚩尤文化传承有限公司

Making method of convenient coarse cereal porridge

The invention relates to a making method of convenient coarse cereal porridge, and belongs to the field of food processing. Based on synergistic reaction of a superheated steam puffing treatment technique, a yeast light fermentation technique, an extrusion ageing technique and a microwave-hot wind tunnel type drying technique, the convenient coarse cereal porridge is made. The making method comprises main steps of pretreating raw materials, pre-puffing the pretreated materials, performing crushing, adding yeast, performing conditioning, performing extrusion, performing cutting for shaping, performing drying and performing packaging. According to the making method disclosed by the invention, superheated steam is used for pre-puffing cereals, ideal fluffy degree is achieved through the yeastlight fermentation technique, materials are cured and shaped through the extrusion technique, product ageing is delayed through the microwave-hot wind tunnel type drying technique, through the combined action of the superheated steam puffing treatment technique, the yeast light fermentation technique, the extrusion ageing technique and the microwave-hot wind tunnel type drying technique, the madecoarse cereal rice granules can be eaten after being brewed with boiling water for 4-5min, original strong fragrance and granule integrity of the cereals are basically reserved, the convenient coarsecereal porridge has better chewiness and is free from essence and pigment, and the sense organ and the mouth feel of the convenient coarse cereal porridge are similar to those of coarse cereal porridge cooked at home.

Owner:NANCHANG UNIV

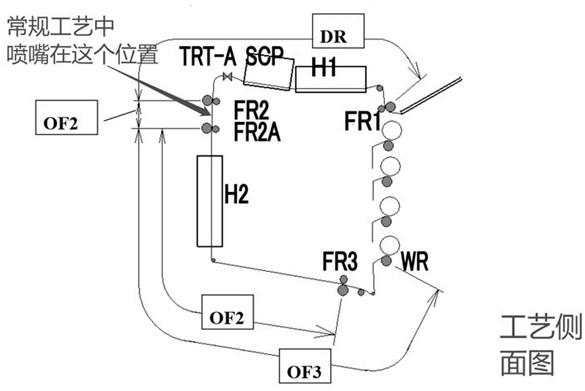

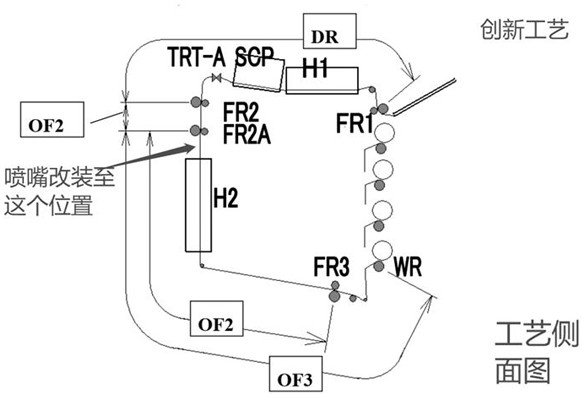

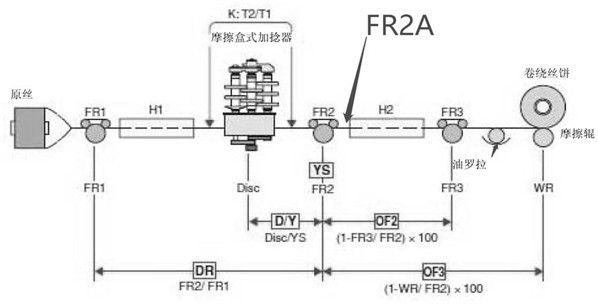

Preparation method of high-bulkiness high-strength DTY (Draw Textured Yarn)

The invention discloses a preparation method of high-bulkiness and high-strength DTY (Draw Textured Yarn), which is characterized in that after a network nozzle is transformed to an FR2A shaft, the speed of the FR2A shaft is greater than that of the FR2 shaft, that is, false-twisted DTY tows are pulled open (cold-drawn) through a speed difference, and after the pulled-open DTY tows are loosened, single fibers are not mutually twisted, so that the high bulkiness of the yarns is kept. And then heat setting is carried out in a second hot box H2, so that the fluffiness stability of the DTY tows is improved. And different network styles of the yarns can be realized by adjusting the speed difference between the FR2A shaft and the FR3 shaft. And the DTY with high strength and high bulkiness is produced.

Owner:CHANGLE HENGSHEN SYNTHETIC FIBER

Preparation method of silk cotton

PendingCN113605086AAvoid damageHigh strengthBiochemical treatment with enzymes/microorganismsDe-gumming silkPolymer scienceActive enzyme

The invention relates to a preparation method of silk cotton. The method comprises the following steps of putting silkworm cocoons into a neutral solution for degumming, and fermenting and rotting the degummed silkworm cocoons under the action of active enzyme and sodium silicate. Through the design of the degumming process and the fermenting and rotting process, the damage to the silk cotton is reduced, degumming can be efficiently carried out, and the peculiar smell of silk fibers can be effectively removed, so that the prepared silk cotton has the advantages of being good in strength, good in filling power, good in glossiness and free of peculiar smell.

Owner:SUZHOU JIAHE SERICULTURE BIOTECHNOLOGY CO LTD

Fragrant degerming pea wood composite cat litter and preparation method for same

InactiveCN106376471AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateFeces

The invention belongs to the technical field of cat litter technology and in particular relates to a fragrant degerming pea wood composite cat litter and a preparation method for the same. Pea wood can give out weak fragrant smell during the processing, so the cat litter made of the pea wood is fragrant and has low density, great water absorbing capacity, filling power, bacteria resistance and absorbing ability; and the cat litter can be biodegraded, thereby being green and environment-protective, so lift environment of cats can be effectively improved; cat litters can be regularly cast into soil, so soil can be improved; containing animal waste, the cat litter can work as organic fertilizer, so resource can be saved. In the preparation method, pea wood is matched with filling wood material, antibacterial agent, sodium bicarbonate and binders; a vertical circular mold granulator is applied, so particle size of cat litter particles is even and fine; great fluffiness can be achieved, so the cat litter has great absorbing capacity for excrement odor; and great yield can be provided, and production efficiency can be improved.

Owner:YANTAI CHINA PET FOODS GRP

Manufacturing technology for far-infrared polyester short fibers

InactiveCN102560732BLow costPromote environmental protectionHollow filament manufactureArtificial filament heat treatmentEnvironmental resistancePolyester

The invention discloses a manufacturing technology for far-infrared polyester short fibers, which takes recycled PET (Polyethylene Terephthalate) as a raw material, and the recycled PET is processed sequentially through pretreatment, rotating drum drying, melt spinning, cooling formation, winding, drawing, curling, oil application, cutting and heat setting, so as to obtain finished products, wherein in the rotating drum drying step, the recycled PET is dried for 5.5 to 6.5 hours firstly, then far-infrared master batches are added, the final mass fraction of the far-infrared master batches ranges from 5 to 7 percent, the total drying time ranges from 9.5 to 10.5 hours, and far-infrared ceramic powders account for 19 to 21 percent in the far-infrared master batches; in the melt spinning step, the temperatures of a screw bolt and a spinning box body of a screw bolt extruder range from 268 to 278 DEG C, and cooling formation is carried out through circular air blow; in addition, the total drawing ratio is 3.0 to 3.5, the heat setting temperature ranges from 162 to 168 DEG C, and the heat setting time ranges from 8 to 12 minutes. The manufacturing technology can save cost and is beneficial to environmental protection, and the prepared finished products achieve good warmth retention and health protection properties.

Owner:HANGZHOU BEST CHEM FIBER

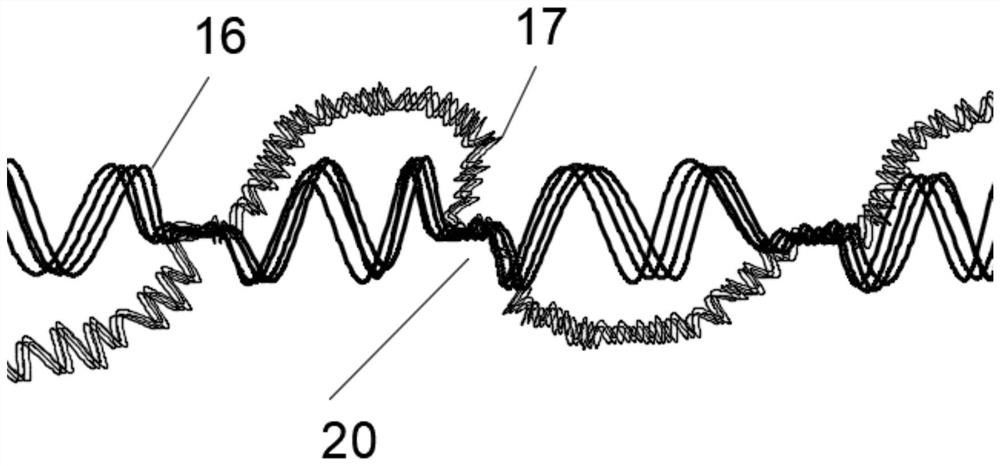

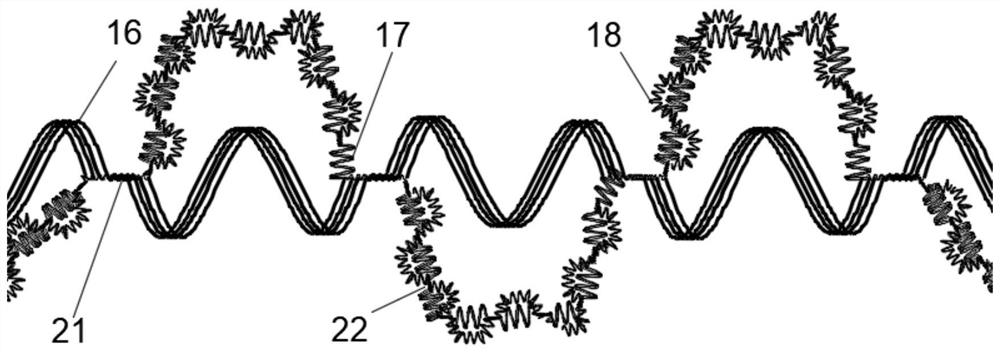

Bionic fiber and bionic fiber manufacturing device

ActiveCN114108148AGood hollownessRealize the effect of biomimetic structureHollow filament manufactureFilament/thread formingPolymer scienceEngineering

The invention discloses a bionic fiber and a manufacturing device of the bionic fiber, the bionic fiber comprises a bionic structure formed by sequentially entangling a plurality of silk threads, the entangled fiber is a three-dimensional fiber structure formed around a main fiber in any direction in the radial direction, the plurality of silk threads comprise a first type of silk and a second type of silk, closed or semi-closed cavities are formed in the first type of silk and the second type of silk, the first type of silk and the second type of silk are entangled to generate first network points, the first type of silk is a bionic fiber main body, namely a velvet core-imitating structure, and the second type of silk is attached to the surface of the first type of silk in an entangled manner to form a velvet silk-imitating structure. Monofilaments of the second type of filaments form a secondary velvet filament imitating structure. By adopting the bionic fiber disclosed by the invention, extremely high heat retention property and service life can be ensured, and excellent bulkiness can also be ensured.

Owner:DONGHUA UNIV

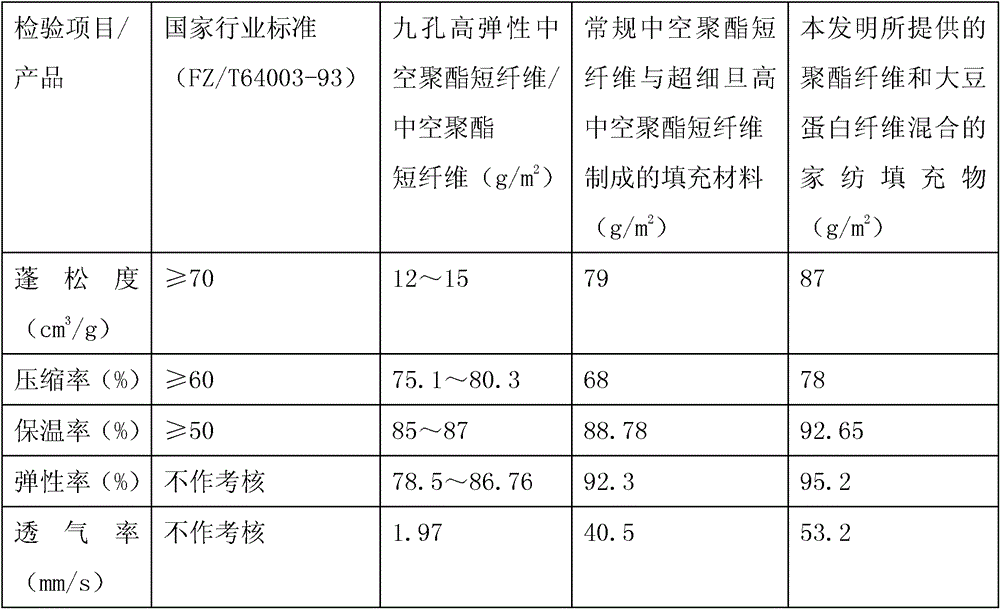

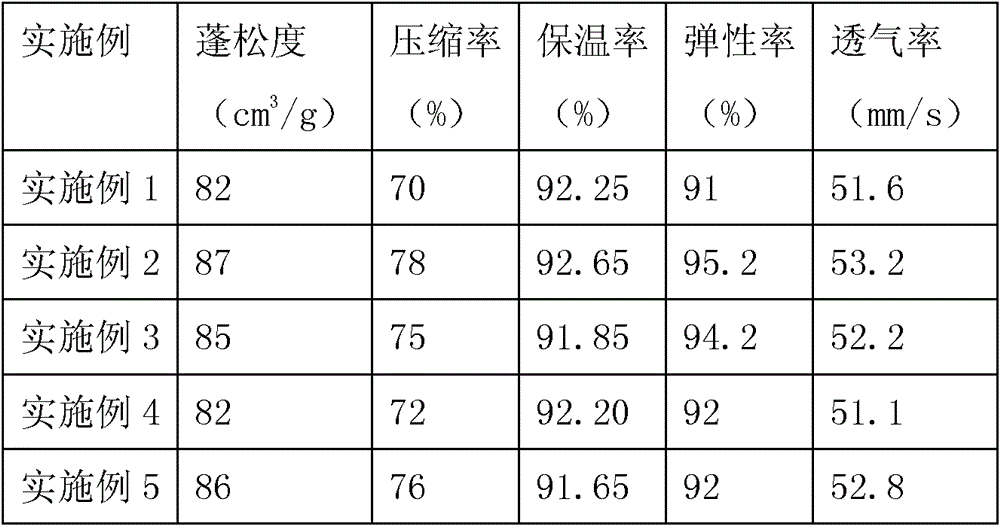

Home textile filler mixed with polyester fiber and soybean protein fiber and preparation method thereof

The invention discloses home textile filler mixing with polyester fibers and soybean protein fibers. The home textile filler is characterized in that the home textile filler is formed by mixing with common hollow polyester short fibers and soybean protein fibers, wherein the fiber number of the used hollow polyester short fibers is 6.67DTEX, the hollow degree is 10 percent, and the length is 38mm; the fiber number of the used soybean protein fibers is 1.5-3.0DTEX, the length is 38mm, and curl fibers are used for the soybean protein fibers; and the weight percentage of the hollow polyester short fibers and the soybean protein fibers is that the hollow polyester short fibers take up by 25-75 percent, and the soybean protein fibers take up by 25-75 percent. The invention further provides a preparation method for the home textile filler mixing with the polyester fibers and the soybean protein fibers. Various stuffing products prepared by the home textile filler mixing with polyester fibers and soybean protein fibers have the advantages that the appearance is uniform and smooth, lightness, a high fluffy degree, continuous elastic restoration, excellent heat preservation, and soft feel, thus people feel comfortable, and the quality of sleep and life can be improved.

Owner:SOUTH BEDDING TECH

Aroma degerming apricot-wood composite litter box and preparing method thereof

InactiveCN106342705AImprove antibacterial propertiesImprove adsorption capacityAnimal housingSodium bicarbonateAnimal science

The invention belongs to technical field of litter box, especially relates to an aroma degerming apricot-wood composite litter box and a preparing method thereof. Apricot-wood can emit slight fragrant and sweet smell in processing. The litter boxis featured in small density, good water-absorbing quality, filling power, antibacterial property and absorptive property. The litter box is capable of biodegradation and environmental protection, to effectively improve living environment of cat. The regularly removed litter box can improve soil and animal waste can act as organic fertilizer, which saves resources. The preparing methodis to make apricot-wood, filling wood, antibacterial agent, sodium bicarbonate and binder react, and adopt vertical circular mould granulator to make litter box particles have uniform size, tiny aperture, and good filling power, which guarantees strong absorption of abnormal taste of excrement and has big output and production efficiency.

Owner:YANTAI CHINA PET FOODS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com