High-density microfiber wiping cloth and processing method thereof

A technology of superfine fiber and processing method, applied in the direction of fiber treatment, application, cleaning machinery, etc., can solve the problems of difficult to take away dirt, secondary pollution, low fiber opening rate, etc., to achieve wiping performance and dirt storage Superior scale performance, high liquid absorption and retention rate, and good bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

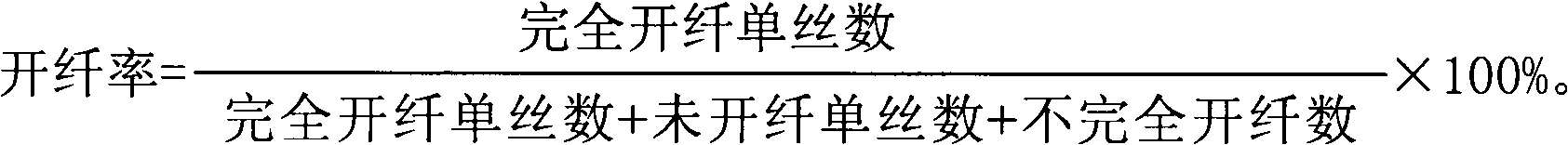

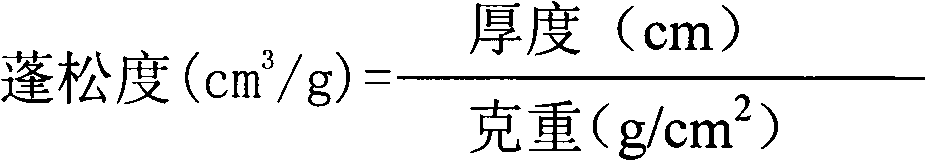

Embodiment 1

[0022] Use 75D-36f polyester / nylon composite false twisted stretched yarn (completely split type), weave the double-ribbed fabric on the E28 or E36 double-sided large circular machine to obtain the knitted gray fabric, and then use 0.9%, 95 ℃ caustic soda solution for 30 minutes, Make the reduction rate reach 5%, then soak in 100g / L, 98 ℃ benzyl alcohol solution for 10 minutes, obtain the product. The fiber opening rate of the polyester-nylon composite filament in the final product reaches 100%, and the bulkiness is 3.0cm 3 / g; According to the JIS 1096 8.26.1A method, the ventilation volume is 18cm 3 / cm 2 / sec.

[0023] Use this product at 670g / cm 2 Wipe the glass surface coated with wiping solvent once under pressure. It is observed that there is basically no white mist, wiping marks or scratches on the surface. The wiping effect is excellent.

Embodiment 2

[0025] Use 75D-36f polyester / nylon composite false twisted stretched yarn (8+1 type, polyester as petals, nylon as core) to make 2 / 2 twill weave or crepe weave with tissue cycle of 118*120 to obtain woven gray fabric, and then Soak in 1.2% caustic soda solution at 95°C for 30 minutes, so that the weight reduction rate reaches 10%, and then soak in 50 g / L benzyl alcohol solution at 98°C for 20 minutes to obtain the product. The fiber opening rate of the polyester / nylon composite filament in the final product reaches 100%, and the bulkiness is 1.5cm 3 / g; According to the JIS 10968.26.1A method, the ventilation volume is 10cm 3 / cm 2 / sec.

[0026] Use this product at 670g / cm 2 Wipe the glass surface coated with wiping solvent once under pressure. It is observed that there is basically no white mist, wiping marks or scratches on the surface. The wiping effect is excellent.

Embodiment 3

[0028] Use 100D-48f polyester / nylon composite false twisted stretched yarn (8+1 type, polyester as valve, nylon as core) as weft yarn, 50D-24f or 50D-36f polyester fully drawn yarn to make 5 pieces and 2 fly The satin weave is used to obtain woven gray fabric, and then soaked in 1.2% caustic soda solution at 95°C for 20 minutes to make the weight loss rate reach 5%, and then soaked in 100g / L benzyl alcohol solution at 98°C for 10 minutes to obtain the product. The fiber opening rate of the polyester / nylon composite filament in the final product reaches 100%, and the bulkiness is 2.5cm 3 / g; According to the JIS1096 8.26.1A method, the ventilation volume is 15cm 3 / cm 2 / sec.

[0029] Use this product at 670g / cm 2 Wipe the glass surface coated with wiping solvent once under pressure. It is observed that there is basically no white mist, wiping marks or scratches on the surface. The wiping effect is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Loft | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com