A kind of high strength, high thermal stability poly-4-methyl-1-pentene microporous membrane and preparation method thereof

A high thermal stability, microporous film technology, applied in flat products, other household appliances, structural parts, etc., can solve problems such as explosion, lithium battery short circuit, poor thermal shrinkage performance, etc., to achieve simple process operation, high liquid absorption Effect of liquid retention rate and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

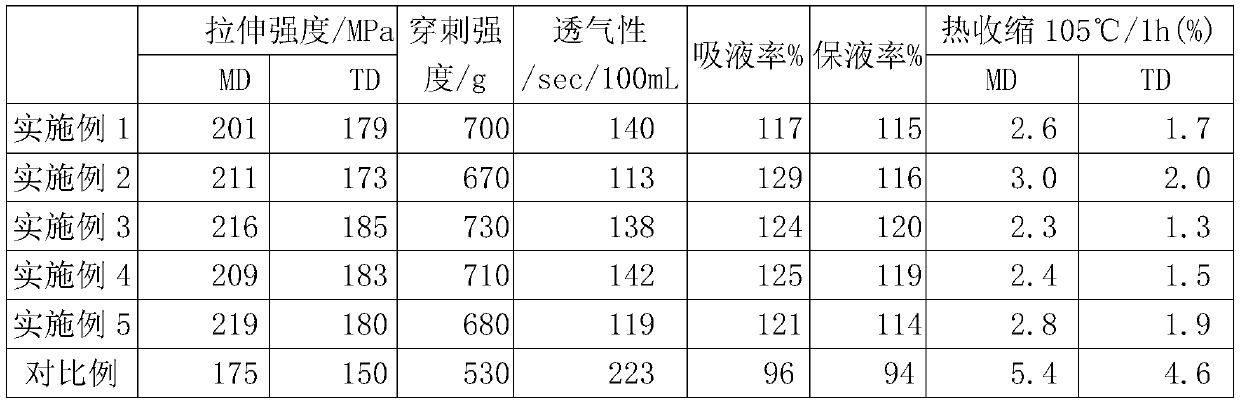

[0025] Weigh 50 parts of TPX (molecular weight is 1×10 5 , crystallinity is 30%), 0.05 part of antioxidant (antioxidant 1010), 50 parts of paraffin oil, TPX and antioxidant are delivered to the extruder in proportion, and then the paraffin oil is delivered to the extruder by the auxiliary machine Out of the machine, the TPX mixed melt is formed by plasticizing and miscible with the extruder, and cast into sheets by cooling rolls, and the TPX microporous membrane is obtained after biaxial stretching, extraction and drying, and heat treatment and setting. The working temperature of the extruder is 240 ℃, die head temperature 280 ℃, screw speed 50rpm / min, output pressure 15Mpa, cooling roll temperature 60 ℃, biaxial stretching ratio 8×10 times, setting temperature 120 ℃, setting time 1min, the product performance is shown in Table 1.

Embodiment 2

[0027] Weigh 25 parts of TPX (molecular weight is 5×10 6 , crystallinity is 60%), 1 part of antioxidant (antioxidant 168), 75 parts of paraffin oil, TPX and antioxidant are delivered to the extruder in proportion, and then the paraffin oil is delivered to the extruder by the auxiliary machine Out of the machine, the TPX mixed melt is formed by plasticizing and miscible by the extruder, and cast into sheets by cooling rollers, and the TPX microporous membrane is obtained after biaxial stretching, extraction and drying, and heat treatment and setting. The working temperature of the extruder is 280 ℃, die head temperature 300 ℃, screw speed 150rpm / min, output pressure 45Mpa, cooling roll temperature 60 ℃, biaxial stretching ratio 8×10 times, setting temperature 120 ℃, setting time 1min, the product performance is shown in Table 1.

Embodiment 3

[0029] Weigh 30 parts of TPX (molecular weight is 2×10 5 , crystallinity is 35%), 0.1 part of antioxidant (antioxidant 1010), 69.5 parts of paraffin oil, transport TPX and antioxidant to extruder in proportion, then paraffin oil is transported to extruder by auxiliary machine Out of the machine, the TPX mixed melt is formed by plasticizing and miscible with the extruder, and cast into sheets by cooling rolls, and the TPX microporous membrane is obtained after biaxial stretching, extraction and drying, and heat treatment and setting. The working temperature of the extruder is 240 ℃, die head temperature 280 ℃, screw speed 50rpm / min, output pressure 25Mpa, cooling roll temperature 60 ℃, biaxial stretching ratio 8×10 times, setting temperature 120 ℃, setting time 1min, the product performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com