Insulation flaked material and preparation method and insulation product thereof

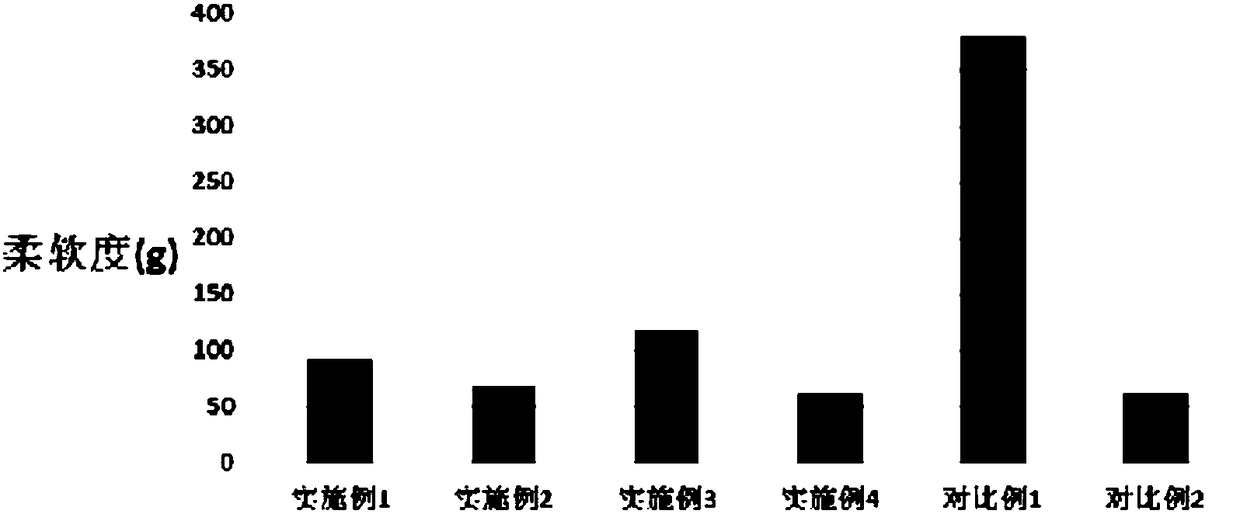

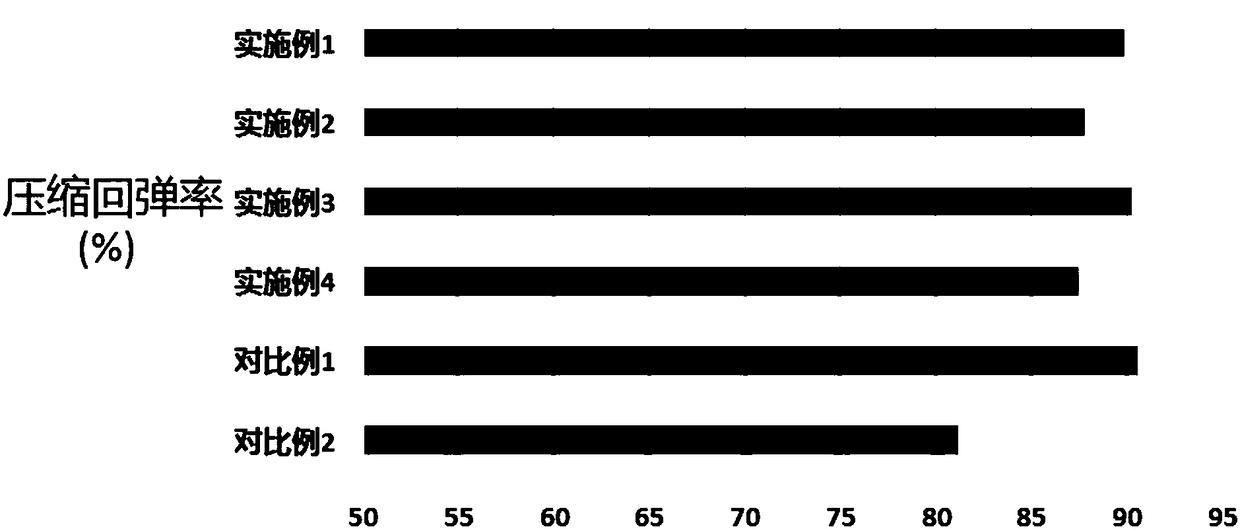

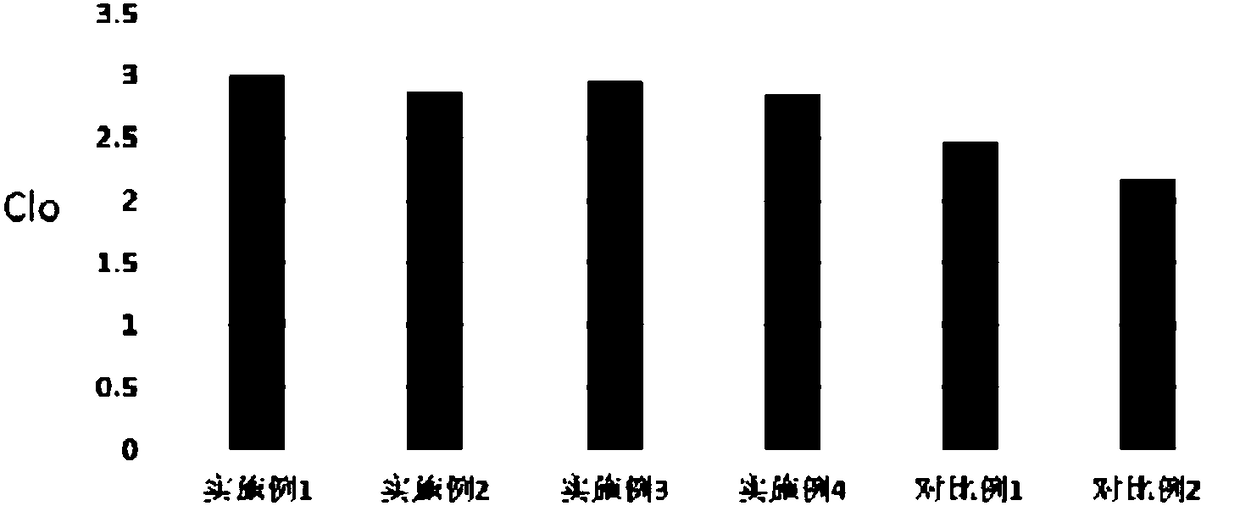

A technology for thermal insulation products and flakes, which is used in textiles and papermaking, non-woven fabrics, adhesives, etc., and can solve the problems that thermal insulation flakes are difficult to obtain at the same time, such as softness, resilience, bulkiness, thermal insulation, etc. Elasticity, the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] Preparation method of thermal insulation flake material

[0089] The present invention also provides a method for preparing the above-mentioned thermal insulation flake material, which includes:

[0090] Stacking multi-layer fiber single nets;

[0091] Heat setting treatment is performed on the stacked multi-layer fiber monowebs.

[0092] That is to say, fiber single nets can be formed by carding first, and then layers of multi-layer fiber single nets are laid together by laying (such as cross-laying), and then these stacked fiber single nets are heat-set. (For example, treat at a temperature of 120-180°C for 5-15 minutes), so that it can form a thermal insulation flake material.

[0093] Insulation products

[0094] The invention provides a thermal insulation product, which comprises:

[0095] an enclosure defining an enclosed interior space;

[0096] The above-mentioned thermal insulation flake material arranged in the closed inner space defined by the coveri...

Embodiment 1

[0130] Using 3kg of cellulose fiber 1, 3kg of first-type fiber 1, 2kg of first-type fiber 2, and 2kg of low-melting point elastic fiber 1 as raw materials, use Jiangsu Yingyang Nonwoven Machinery scx26 type spray-bonded cotton production line, by mixing -The process of opening-carding-cross-lapping forms a multi-layer network structure with a grammage of 100gsm, and then heat-setting at 145°C for 6-9 minutes to keep the wadding material.

Embodiment 2

[0132] Using 4kg of cellulose fiber 1, 2kg of first-type fiber 3, 1.5kg of first-type fiber 4, and 2.5kg of low-melting point elastic fiber 2 as raw materials, Jiangsu Yingyang Nonwoven Machinery scx26 spray-bonded cotton production line was used. Through the process of mixing-opening-carding-cross-lapping, a multi-layer network structure with a grammage of 100gsm is formed, and then heat-set at 145°C for 6-9 minutes to keep the flake material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com