Multifunctional moisture absorption and sweat releasing finishing agent and preparation method therefor

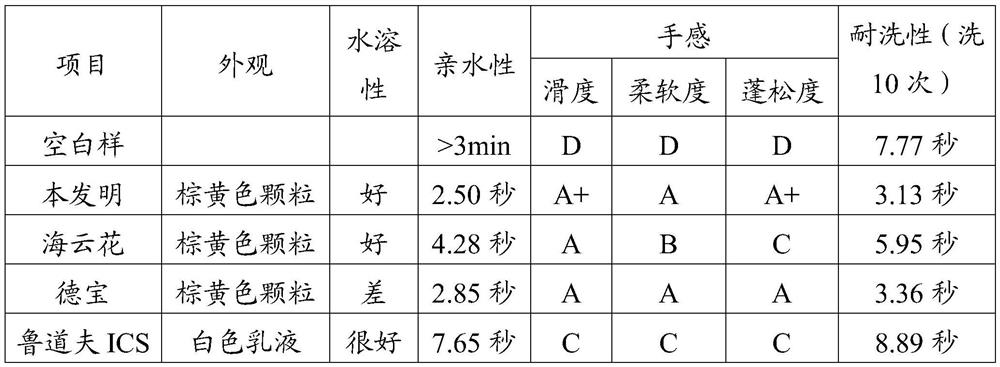

A technology of moisture absorption and perspiration, finishing agent, applied in the direction of fiber treatment, improved hand fiber, textile and paper making, etc., can solve the problems of poor washing resistance, poor hand feeling of the fabric after, and achieve excellent water absorption, hydrophilicity and stability. The effect of improved washfastness and excellent bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

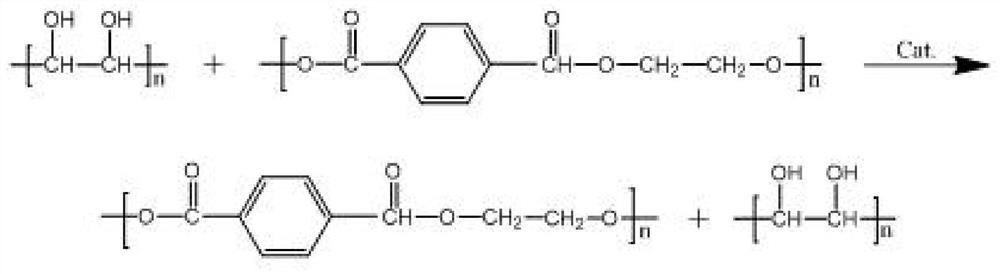

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a multifunctional moisture wicking finishing agent, comprising the following steps:

[0024] Step 1: drying polyethylene terephthalate at 103°C for 2h;

[0025] Step 2: add polyethylene terephthalate, polyethylene glycol and catalyst dried in step 1 into the reactor, fill with nitrogen to 0.1Mpa, and heat in an oil bath;

[0026] Among them, the mass ratio of polyethylene terephthalate: polyethylene glycol is 40~45:140~150

[0027] The catalyst is zinc acetate. The catalyst accounts for 0.04-0.08% of the total mass of polyethylene glycol and polyethylene terephthalate.

[0028] Step 3: When the temperature of the material in the reaction kettle reaches 150°C, turn on the mixer for stirring, continue heating, and when the temperature of the material reaches 275°C, vacuumize to -0.1Mpa, and then react at a constant temperature for 5h;

[0029] Step 4: after the reaction is completed, cool down to reduce the temperature to 220-230°C, then add hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com