Fabric containing hollow fiber and production method thereof

A fabric and hollow technology, which is applied in the field of fabrics containing hollow fibers, can solve the problems of insufficient elasticity, yarn hollowness damage, hard hand feeling, etc., achieve soft hand feeling, overcome false twist processing or twisting damage hollowness, and have superior bulkiness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

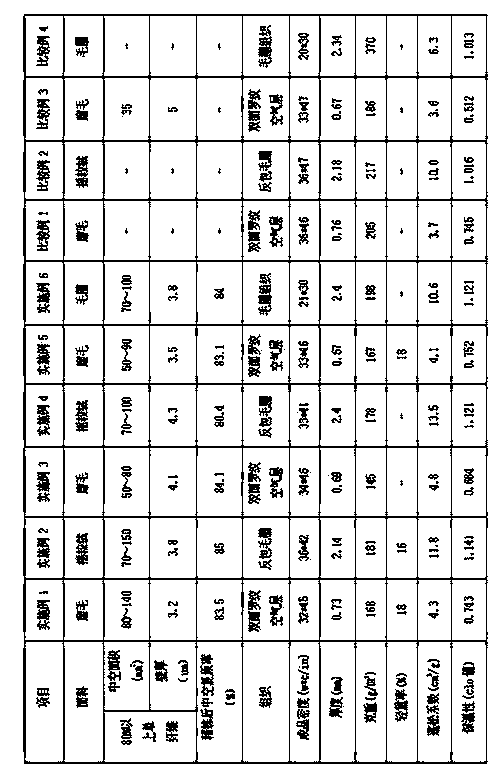

Embodiment 1

[0037] Select 90dtex-36f-flat cross-section hollow cationic dyeable polyester false twist yarn and 33dtex spandex to weave on a 24G 33-inch double-sided circular knitting machine. 2 1. Gray cloth with a door width of 186m, and then through pre-setting-scouring-overflow dyeing-finishing processing (including sanding processing), the weight is 168g / m 2 Knitted brushed fabric, the performance parameters of the obtained fabric are shown in Table 1, and the light weight rate=(grammage of fabric in Comparative Example 1-grammage of fabric in Example 1) / grammage of fabric in Example 1*100%.

[0038] Presetting conditions: 190°C*90 seconds, scouring conditions: scouring agent 2g / l, 95°C*20min, overflow dyeing conditions: cationic dye 6%owf, 120°C*60min, finishing conditions: soft resin 2g / l l. Water-absorbing resin 4g / l, 130°C for 90 seconds.

Embodiment 2

[0040]Select 90dtex-36f-flat cross-section hollow cationic dyeable polyester false twist yarn, 84dtex-72f-common cationic dyeable polyester false twist yarn and 33dtex spandex to weave on a 24G 30-inch turn-up machine, and the organization is turned-up terry weave , the obtained grammage is 258g / m 2 1. Gray cloth with a width of 184m, and then through pre-setting-scouring-overflow dyeing-finishing processing (including napping, carding, shearing, shaker processing), the weight is 181g / m 2 Knitted fleece fabric, the performance parameters of the obtained fabric are shown in Table 1, and the light weight rate=(gram weight of the fabric of Comparative Example 2-gram weight of the fabric of Example 2) / gram weight of the fabric of Example 2*100%.

[0041] Presetting conditions: 190°C*90 seconds, scouring conditions: scouring agent 2g / l, 95°C*20min, overflow dyeing conditions: cationic dye 5%owf, 120°C*60min, finishing conditions: soft resin 2g / l l. Water-absorbing resin 4g / l, 130°...

Embodiment 3

[0043] 70dtex-36f-flat cross-section hollow cationic dyeable polyester false twist yarn and 33dtex spandex are used for weaving on a 24G 30-inch double-sided circular knitting machine. 2 1. Gray cloth with a door width of 170m, and then through pre-setting-scouring-overflow dyeing-finishing processing (including sanding processing), the weight is 145g / m 2 The various performance parameters of the obtained fabric are shown in Table 1.

[0044] Presetting conditions: 180°C*50 seconds, scouring conditions: scouring agent 1g / l, 75°C*20min, overflow dyeing conditions: cationic dye 5%owf, 120°C*40min, finishing conditions: soft absorbent resin 12g / l, 130°C*60 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com