Spunbond two-component fiber non-woven fabric and processing equipment and technology thereof

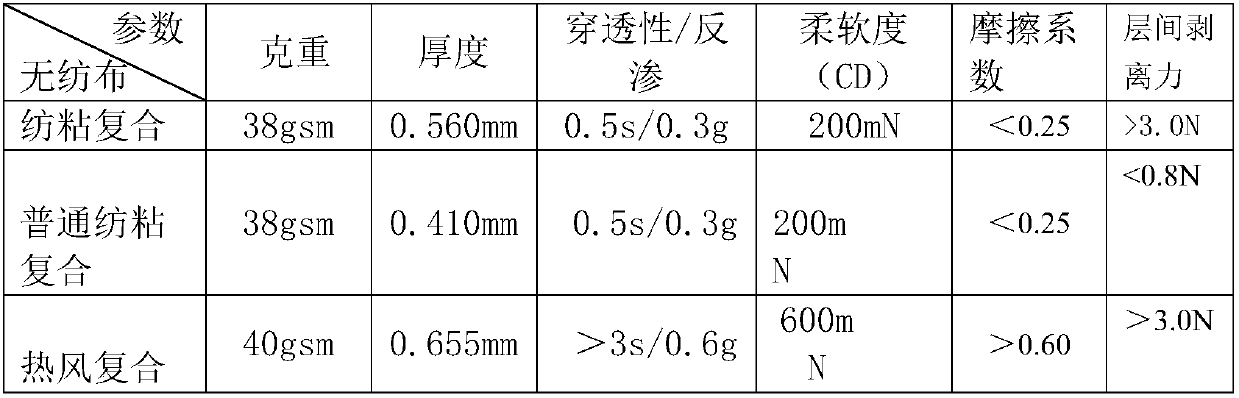

A two-component fiber and processing technology, applied in the field of raw materials for hygiene products, can solve the problems of high weight, low bulkiness, hard hand feeling, etc., and achieve the effects of good softness, excellent bulkiness, and extensive social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

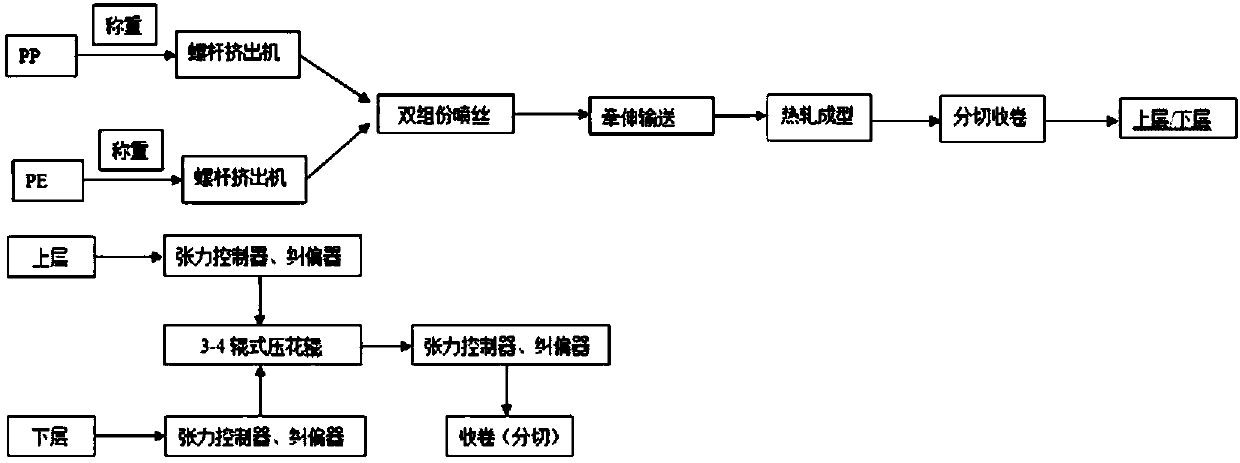

[0024] Such as figure 1 As shown, a spun-bonded bicomponent fiber nonwoven fabric includes an upper layer 1 and a lower layer 2 that are composited together. The upper layer 1 is composed of 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles through the screw extruder to extrude the two-component products respectively, and then spray them out through the two-component spinneret hole to form a "skin-core The surface layer of the structure is a surface layer structure formed by bonding PE to each other, and the lower layer 2 is a two-component product extruded by a screw extruder with 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles. Afterwards, through the two-component spinneret hole, the surface layer PE with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com