Bionic fiber and bionic fiber manufacturing device

A fiber and bionic technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of long production cycle, hollowness cannot be effectively preserved for a long time, and products cannot achieve warmth retention, etc., to achieve excellent bulkiness, high Warmth retention and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

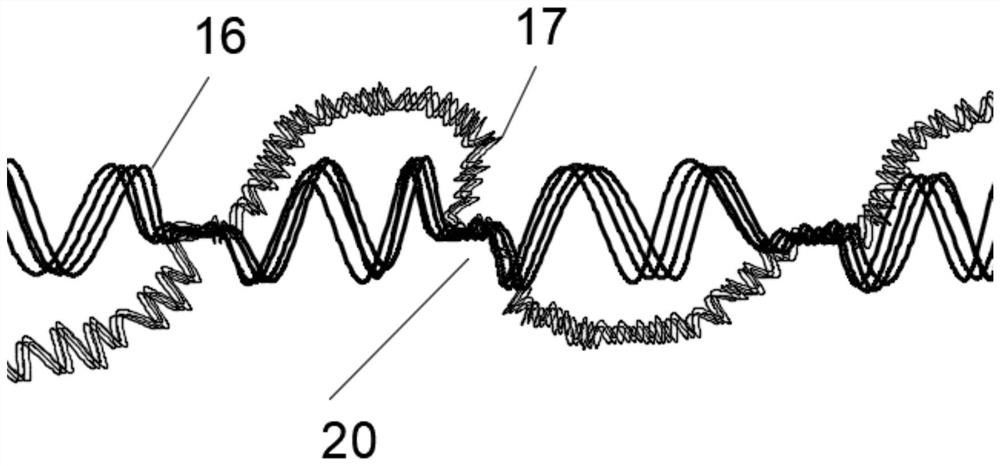

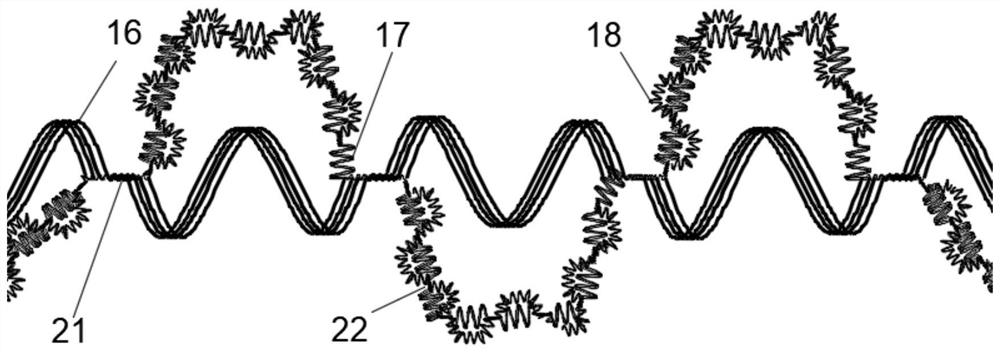

[0028] Such as figure 1 The illustrated biomimetic fibers include a first type of filament 16 and a second type of filament 17 . The second type of filament 17 is entangled on the surface of the first type of filament 16 to form a bionic fiber similar to velvet. The second type of filaments 17 and the first type of filaments 16 form network points 20 under the action of the network nozzles, making them entangled. Under different overfeeding conditions, the lengths of the filaments 16 and 17 between the two network points are different, thus forming a better three-dimensional structure. The first type of silk 16 is a bionic fiber main body, that is, the imitation velvet core structure, and the second type of silk 17 is attached to the surface of the first type of silk 16 by entanglement to form a velvet-like structure, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com