Multiple-hollow-fiber spinneret plate

A spinneret and fiber technology, which is applied in the manufacture of hollow filaments, fiber chemical characteristics, rayon manufacture, etc., can solve the problems of low hollowness and achieve the effect of good hollowness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

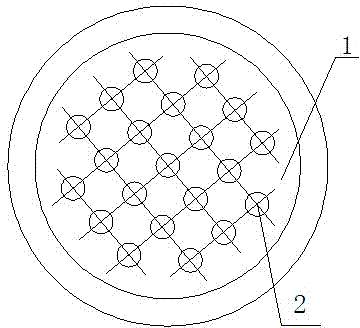

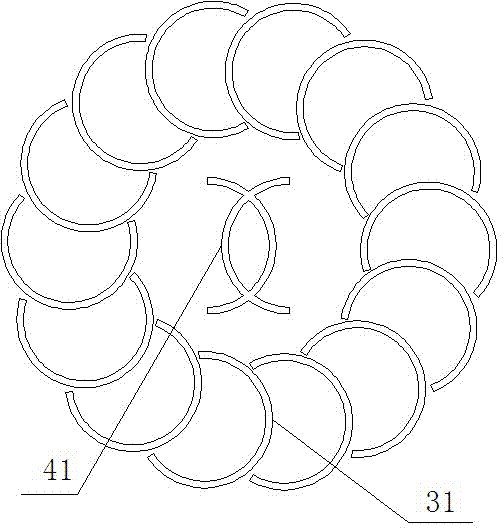

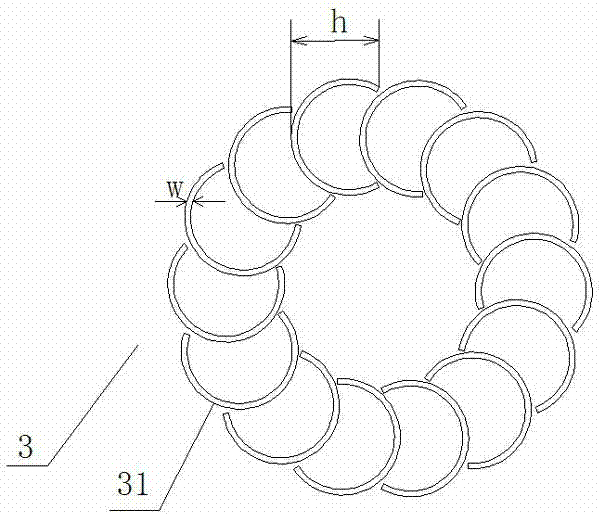

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of multi-hollow fiber spinneret comprises circular spinneret 1, is provided with several spinneret holes 2 on spinneret 1, and spinneret hole 2 of the present invention is in the shape of a spinneret 1 on spinneret 1. Font arrangement. The microholes of spinneret hole 2 are composed of two layers of coaxial ring holes spliced together, such as figure 2 As shown, the cross-sectional shape of the first layer of annular holes 3 includes fourteen C-shaped slits 31, and the C-shaped slits 31 are arranged in a circular ring in the same direction, as image 3 As shown; the cross-sectional shape of the second layer ring hole 4 is composed of two semicircular slits 41 reversely cross-connected, as Figure 4 Shown; Two semicircular slits 41 on the second layer of ring hole 4 are facing the middle position of the first layer of ring hole 3, as figure 2 shown.

[0022] Further, the opening depth (h) of t...

Embodiment 2

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of multi-hollow fiber spinneret comprises circular spinneret 1, is provided with several spinneret holes 2 on spinneret 1, and spinneret hole 2 of the present invention is in the shape of a spinneret 1 on spinneret 1. Font arrangement. The microholes of spinneret hole 2 are composed of two layers of coaxial ring holes spliced together, such as figure 2 As shown, the cross-sectional shape of the first layer of annular holes 3 includes fourteen C-shaped slits 31, and the C-shaped slits 31 are arranged in a circular ring in the same direction, as image 3 As shown; the cross-sectional shape of the second layer ring hole 4 is composed of two semicircular slits 41 reversely cross-connected, as Figure 4 Shown; Two semicircular slits 41 on the second layer of ring hole 4 are facing the middle position of the first layer of ring hole 3, as figure 2 shown.

[0025] Further, the opening depth (h) of t...

Embodiment 3

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of multi-hollow fiber spinneret comprises circular spinneret 1, is provided with several spinneret holes 2 on spinneret 1, and spinneret hole 2 of the present invention is in the shape of a spinneret 1 on spinneret 1. Font arrangement. The microholes of spinneret hole 2 are composed of two layers of coaxial ring holes spliced together, such as figure 2 As shown, the cross-sectional shape of the first layer of annular holes 3 includes fourteen C-shaped slits 31, and the C-shaped slits 31 are arranged in a circular ring in the same direction, as image 3 As shown; the cross-sectional shape of the second layer ring hole 4 is composed of two semicircular slits 41 reversely cross-connected, as Figure 4 Shown; Two semicircular slits 41 on the second layer of ring hole 4 are facing the middle position of the first layer of ring hole 3, as figure 2 shown.

[0028] Further, the opening depth (h) of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com