A kind of palm fiber home textile mat and preparation method thereof

A palm fiber and home textile technology, which is applied to chemical instruments and methods, chemical methods to produce bast fibers, textiles and papermaking, etc., can solve the problems of harsh source of raw materials, high cost of preparing summer mats, complicated preparation steps, etc. Excellent moisture conductivity and surface dryness, excellent capillary effect, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

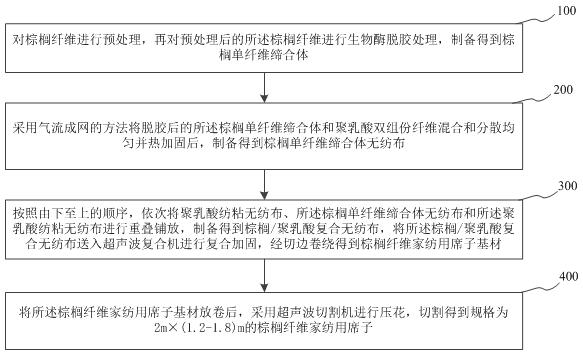

[0060] figure 1 It is a method flow chart of a preparation method of a palm fiber home textile mat shown according to an exemplary embodiment, such as figure 1 As shown, the preparation method of the palm fiber home textile mat is shown in steps 100 to 400, including:

[0061] In step 100, the palm fiber is pretreated, and then the pretreated palm fiber is subjected to biological enzyme degumming treatment to prepare a palm single fiber association.

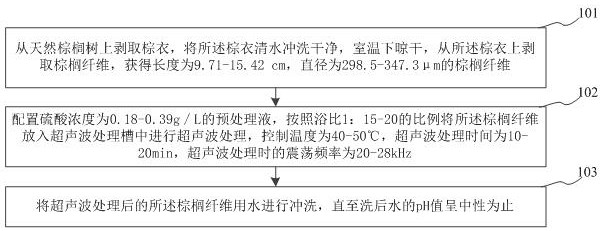

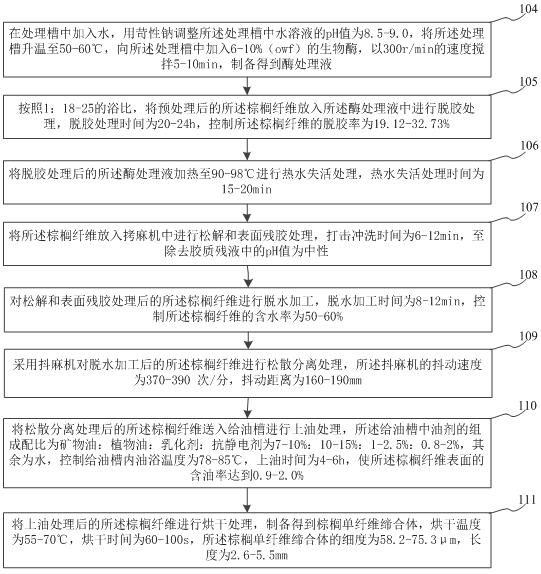

[0062] In a preferred embodiment, the flow chart of the method for pretreatment of palm fiber is as follows figure 2 shown in figure 2 , the steps of pretreatment of palm fiber include:

[0063] Step 101: peel off the brown coat from the natural palm tree, rinse the brown coat with clean water, dry at room temperature, and peel off the palm fiber from the brown coat to obtain a length of 9.71-15.42 cm and a diameter of 298.5- 347.3 μm palm fiber.

[0064] Step 102: configure a pretreatment solution with a sulfuric acid con...

Embodiment 1

[0096] (1) Pretreating palm fibers, and then degumming the pretreated palm fibers with biological enzymes to prepare palm single fiber associative bodies:

[0097] a. Peel off the brown coat from the natural palm tree, rinse the brown coat with clean water, dry at room temperature, and peel off the palm fiber from the brown coat to obtain a palm fiber with a length of 9.71 cm and a diameter of 298.5 μm ;

[0098] b. Configure a pretreatment solution with a sulfuric acid concentration of 0.18 g / L, put the palm fiber into an ultrasonic treatment tank for ultrasonic treatment according to a liquor ratio of 1:20, the control temperature is 40 ° C, and the ultrasonic treatment time is 10 min, The oscillation frequency during ultrasonic treatment is 20kHz;

[0099] c. Rinse the palm fiber after ultrasonic treatment with water until the pH value of the washed water is neutral;

[0100] d. Add water to the treatment tank, adjust the pH value of the aqueous solution in the treatment ...

Embodiment 2

[0122] (1) Pretreating palm fibers, and then degumming the pretreated palm fibers with biological enzymes to prepare palm single fiber associative bodies:

[0123] a. Peel off the brown coat from the natural palm tree, rinse the brown coat with clean water, dry at room temperature, and peel off the palm fiber from the brown coat to obtain a palm fiber with a length of 12.52 cm and a diameter of 314.5 μm ;

[0124] b. Configure the pretreatment solution with sulfuric acid concentration of 0.25g / L, put the palm fiber into the ultrasonic treatment tank for ultrasonic treatment according to the ratio of the liquor ratio of 1:17.2, the control temperature is 45 ℃, the ultrasonic treatment time is 15min, The oscillation frequency during ultrasonic treatment is 24kHz;

[0125] c. Rinse the palm fiber after ultrasonic treatment with water until the pH value of the washed water is neutral;

[0126]d. Add water to the treatment tank, adjust the pH of the aqueous solution in the treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com