Method for preparing WO3.H2O hollow sphere assembled by nanosheets

A technology of hollow spheres and nanosheets, which is applied in the field of preparing nanosheet-assembled WO3·H2O hollow spheres, which can solve the problem that the template is difficult to completely remove and clean, and achieve the effects of uniform size, good dispersion, and strong hollowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

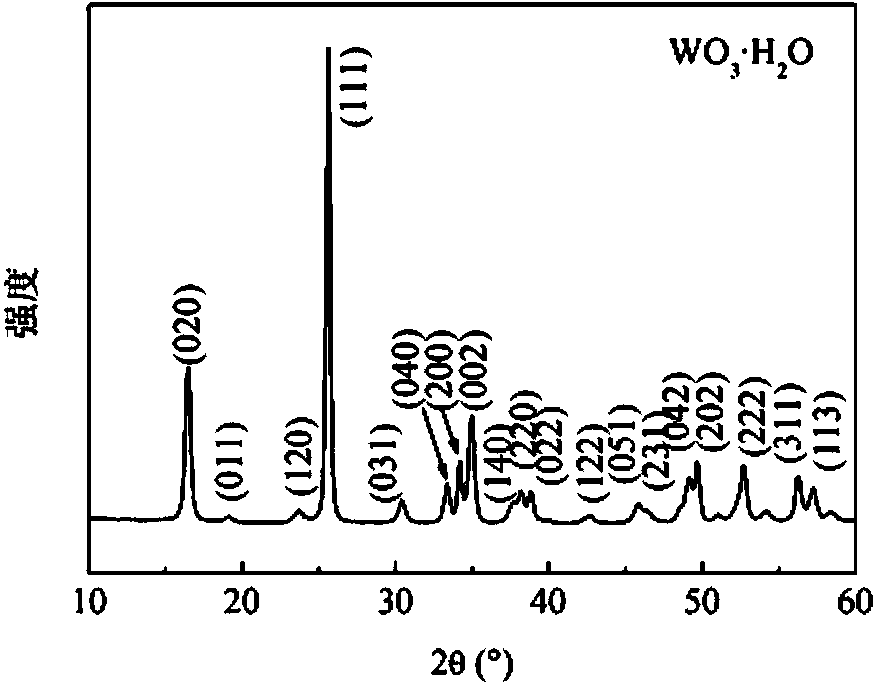

[0043]Under magnetic stirring, add 1mmol oxalic acid and 0.5mmol sodium tungstate to 30mL water, add 36mL propanol to the above aqueous solution to form a mixed solvent of propanol and water, then add 24mmol hydrochloric acid to the above mixed solvent solution, and introduce the resulting solution into 90mL A volumetric polytetrafluoroethylene-lined reaction vessel was incubated at 100°C for 6 hours to obtain a deposit. Then, the obtained sediment was washed several times with ethanol and water respectively, so that there was no residue on the sediment, and after drying, WO was obtained. 3 ·H 2 O powder, the sample is marked as A.

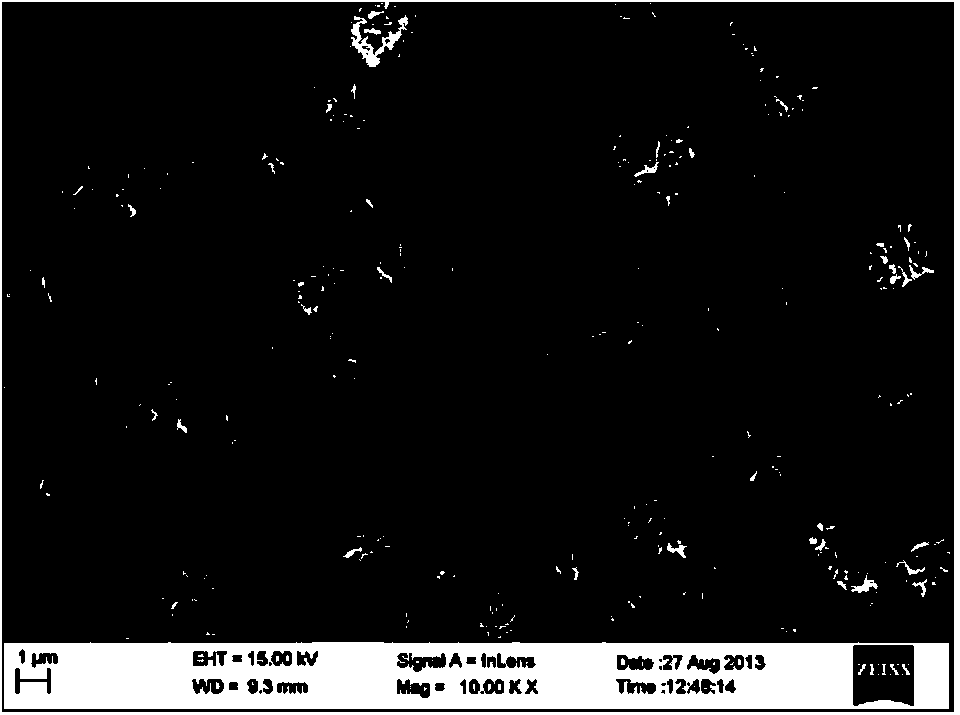

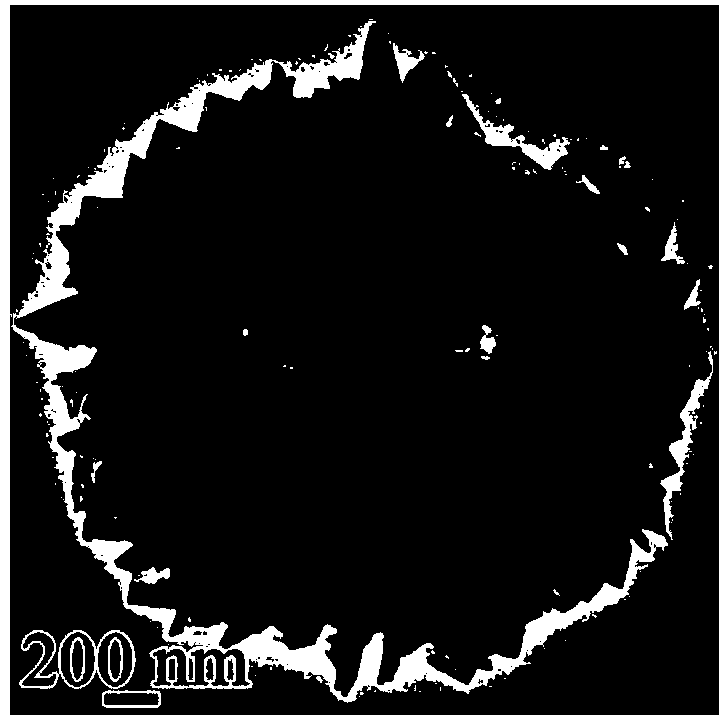

[0044] Adopt the Leo-Supra55 type scanning electron microscope of Carl Zeiss Company of Germany and the 2100 type transmission electron microscope of JEOL to observe the morphology and structure of the sample, as Figure 1(a) , (b) are the SEM and TEM photos of the samples, respectively. As a result, it can be seen that the obtained WO 3 ·H 2 ...

Embodiment 2

[0047] The difference from Example 1 is that under magnetic stirring, 1mmol oxalic acid and 0.5mmol potassium tungstate are added to 30mL water, 36mL propanol is added to the above aqueous solution to form a mixed solvent of propanol and water, and then 12mmol sulfuric acid is added to the above The solvent solutions were mixed, and the resulting solution was introduced into a 90-mL polytetrafluoroethylene-lined reaction kettle, and kept at 50° C. for 24 hours to obtain a deposit. Then, the obtained sediment was washed several times with ethanol and water respectively, so that there was no residue on the sediment, and after drying, WO was obtained. 3 ·H 2 O powder, the sample is marked as B.

[0048] Adopt the transmission electron microscope identical with embodiment 1 to observe sample shape, as figure 2 TEM photo of the sample. As a result, it can be seen that the obtained WO 3 ·H 2 O is a hollow sphere assembled by nanosheets, and its diameter is about 1.8 μm; the de...

Embodiment 3

[0050] The difference from Example 1 is that under magnetic stirring, 1mmol oxalic acid and 0.5mmol potassium tungstate were added to 32mL water, 36mL propanol was added to the above aqueous solution to form a mixed solvent of propanol and water, and then 20mmol nitric acid was added to the above The solvent solutions were mixed, and the resulting solution was introduced into a 90 mL polytetrafluoroethylene-lined reaction kettle, and kept at 70° C. for 10 hours to obtain a deposit. Then, the obtained sediment was washed several times with ethanol and water respectively, so that there was no residue on the sediment, and after drying, WO was obtained. 3 ·H 2 O powder, the sample is marked as C.

[0051] Adopt the transmission electron microscope identical with embodiment 1 to observe sample shape, as image 3 TEM photo of the sample. As a result, it can be seen that the obtained WO 3 ·H 2 O is a hollow sphere assembled by nanosheets, and its diameter is about 2.3 μm; the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com