Agricultural solid waste composting method, fertilizer product and application of fertilizer product

A technology of solid waste and composting method, which is applied in fertilizer, application, agriculture and other directions made of biological waste, can solve the problems of long composting time and low recycling efficiency of agricultural solid waste, and achieves accelerated fermentation and excellent working environment. , the effect of speeding up the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation examples of raw materials and / or intermediates Straw: The straw in this application can be corn straw, soybean straw, wheat straw, etc. This example specifically takes the wheat straw sold by Jiaxing Animal Husbandry Family Farm in Suiping County as an example for illustration.

[0041] Okara: The okara in this application is a by-product in the process of producing soybean milk or tofu. In this embodiment, the feed-grade okara sold by Jinan Xuzhou Chemical Technology Co., Ltd. is used as an example for illustration.

[0042] Rainwater: This application specifically takes the rainwater in Shanghai and Shandong in March as examples for illustration.

[0043] Preparation of fermentation broth:

[0044] Source: Bacillus subtilis was purchased from the freeze-dried powder of Bacillus subtilis from Shandong Yihao Biotechnology Co., Ltd., and the live bacteria content was ≥20 billion cfu / g; Phanerochaete chrysosporium freeze-dried powder, resource number BNCC190652...

Embodiment 1

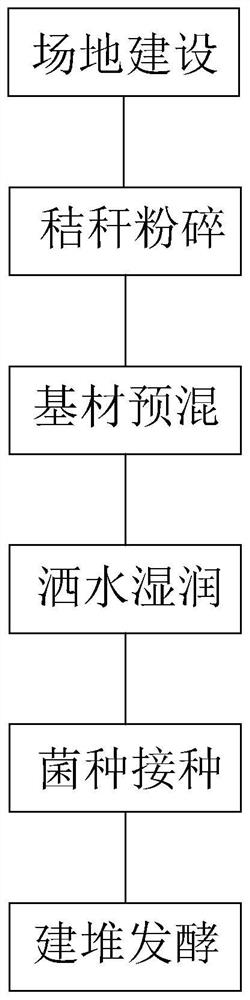

[0052] A kind of composting method of agricultural solid waste, see figure 1 , including the following steps:

[0053] ①. Site construction:

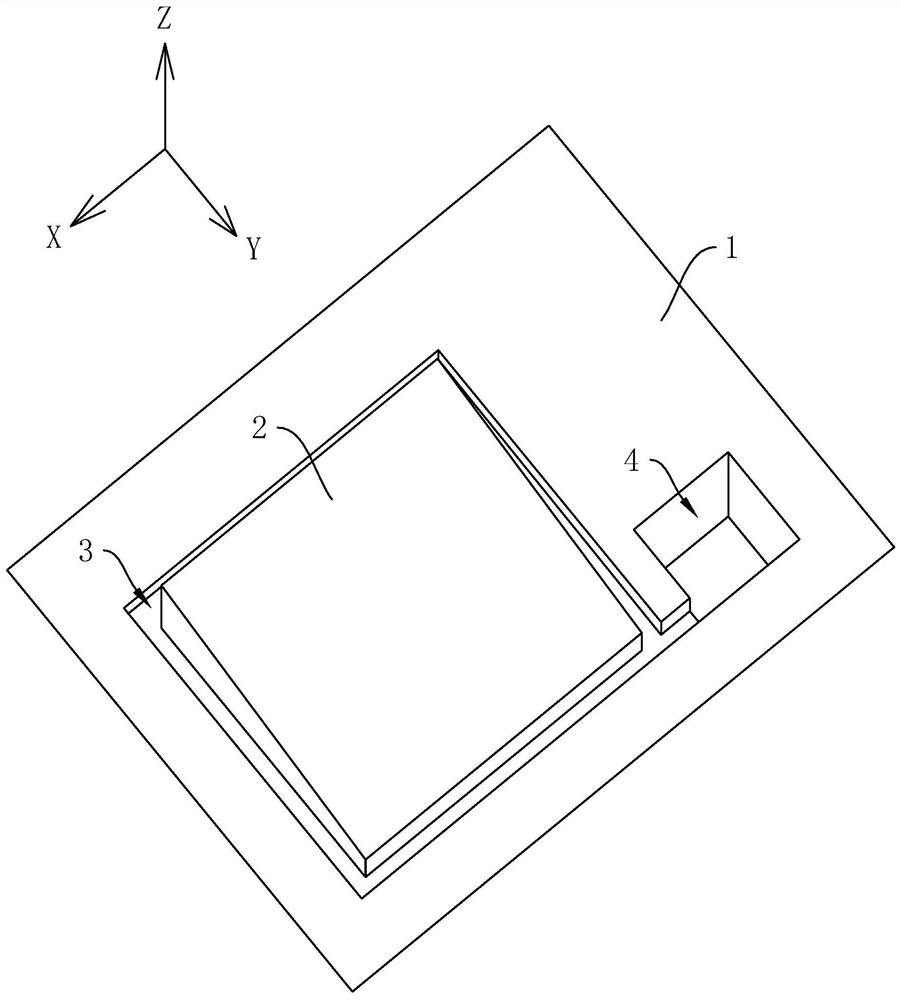

[0054] Choose a place with sufficient light and good ventilation to build a fermentation site 2, combined with figure 2 , this embodiment establishes the XYZ coordinate axis, the positive direction of the X axis refers to the south, the reverse direction of the X axis refers to the north, the positive direction of the Y axis refers to the east, the reverse direction of the Y axis refers to the west, and the positive direction of the Z axis Refers to the top, and the reverse of the Z axis refers to the bottom;

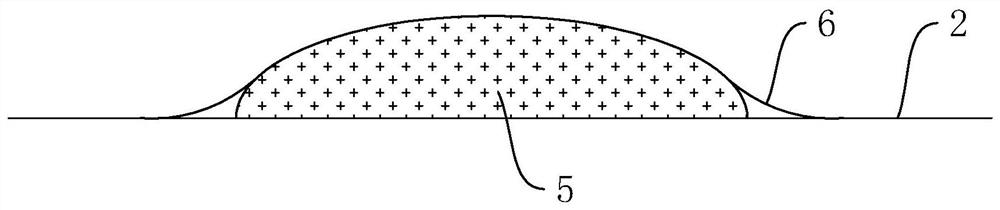

[0055] The topography of the fermentation site 2 is higher than that of the surrounding flat land 1, and the ground of the fermentation site 2 has an inclination of 4-7° relative to the horizontal plane (plane parallel to the XY plane); in this embodiment, the inclination of 5° is specifically Example, and the west-facing sid...

Embodiment 2

[0064] Examples 2-3 On the basis of the method in Example 1, the mass ratio of straw scraps to bean dregs in the base material premixing step was adjusted. Wherein, the mass ratio of straw scraps to bean dregs in Example 2 is 7:1; the mass ratio of straw scraps to bean dregs in Example 3 is 8:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com