Acetic acid resistant ethanol producing wine making yeast strains and strain screening method

A technology of Saccharomyces cerevisiae strain and acetic acid tolerance, which is applied in the field of genetic breeding of industrial microorganisms, can solve the problems of loss of fermentable sugar, increase of production cost, reduction of inhibitor concentration, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

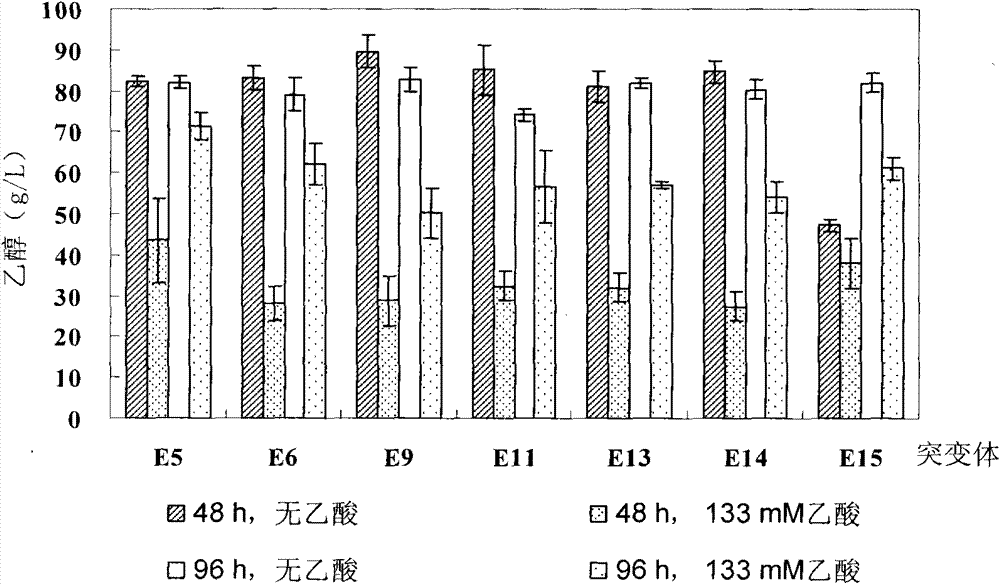

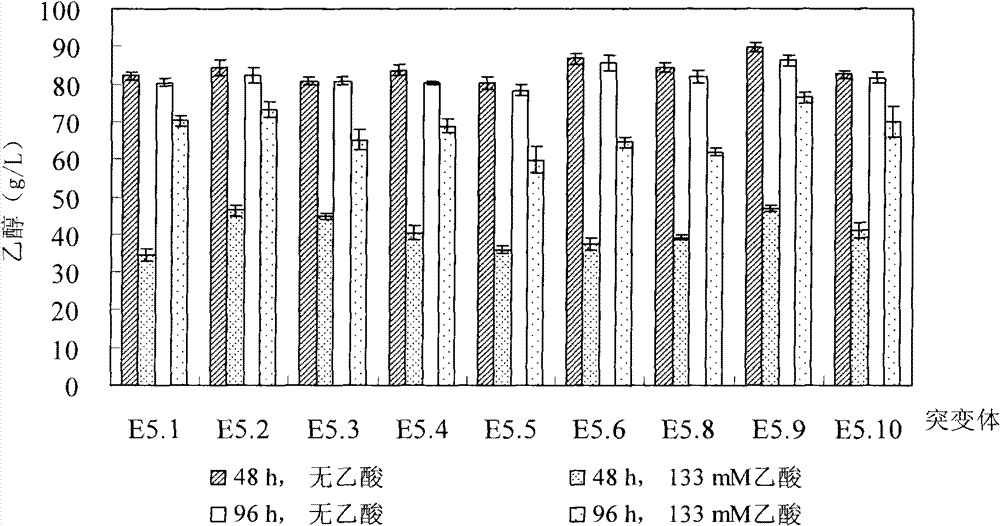

[0040] Example 1: Screening of acetic acid tolerant Saccharomyces cerevisiae E5.9

[0041] 1) Starting strain

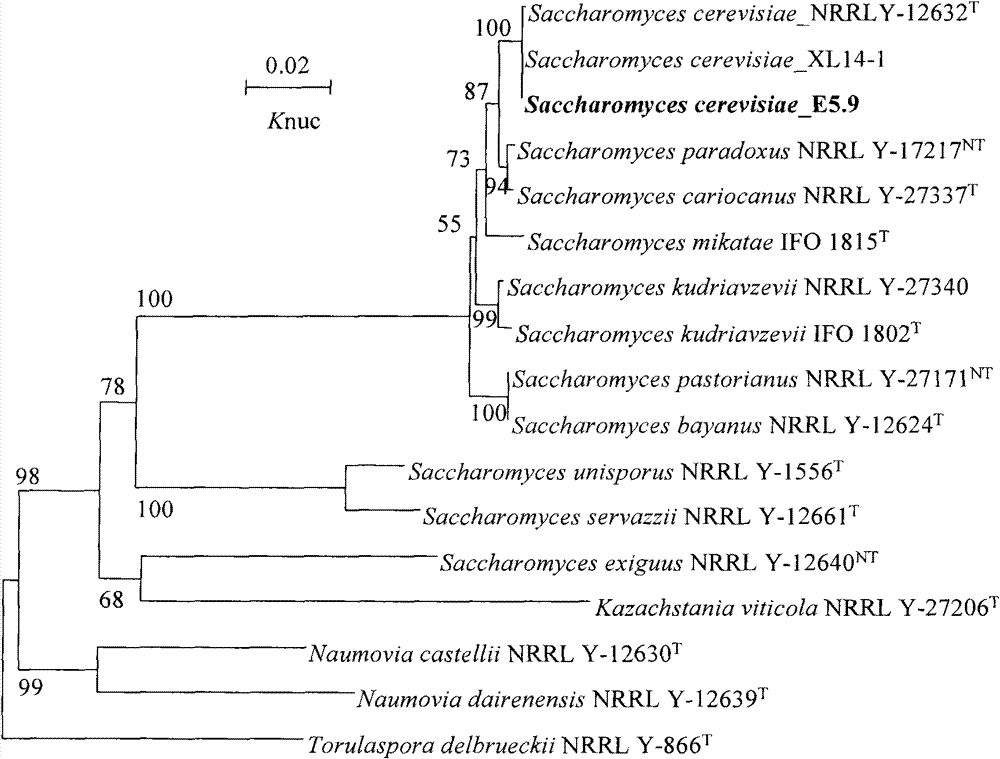

[0042] By analyzing the stress tolerance of 96 Saccharomyces cerevisiae strains from different sources, the strain XL14-1 with strong comprehensive stress resistance was selected as the starting strain. The strains were identified by phenotype and ribosomal gene 26S rDNA D1 / D2 region and ITS region sequence analysis.

[0043] 2) Straw pretreatment fermentation broth

[0044] The solid matter of straw steam explosion pretreatment was provided by COFCO Biochemical Energy (Zhaodong) Co., Ltd., and the hydrolyzate was obtained after repeated extraction. Add glucose 15%, yeast extract 0.6%, peptone 1%, (NH 4 ) 2 SO 4 0.2%, KH 2 PO 4 0.1%, MgSO 4 .7H 2 O 0.15%, CaCl 2 0.055% is made into a pretreatment fermentation liquid, and the final concentration of glucose is 20.5%.

[0045] 3) Mutagenesis

[0046] The three mutagenesis methods adopted in the present inv...

Embodiment 2

[0067] Embodiment 2: Stress resistance screening method - liquid full screening method

[0068] 1. Liquid full screening process

[0069] The method comprises four steps: (1) strain mutagenesis, (2) liquid full screening, (3) solid plate screening, (4) subculture and domestication, wherein liquid full screening is the core of the method, see Figure 5 . First, use ultraviolet, EMS, microwave or other mutagenesis methods to mutate Saccharomyces cerevisiae cells to obtain a library of mutant strains; secondly, transfer all the cells after mutagenesis treatment to a 24-well plate on average, 120 rpm, 30°C pre- Cultivate for 6 hours, then add selective pressure to the pre-cultured bacteria solution, and continue to cultivate until positive mutations of resistance appear; again, dilute the positive mutant bacteria solution and spread the same concentration of solid selection medium, and when colonies grow out, pick large The colony was cultured in the same pressure liquid medium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com