Fabric as well as preparation processes and applications thereof

A process and water cloth technology, applied to cloth and its preparation process and application field, can solve the problems of uniform and disorderly arrangement of fibers, inability to improve the overall quality of non-woven fabrics, poor bulkiness of non-woven fabrics, etc. Low degree of loss, excellent bulkiness and water repellency, good bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

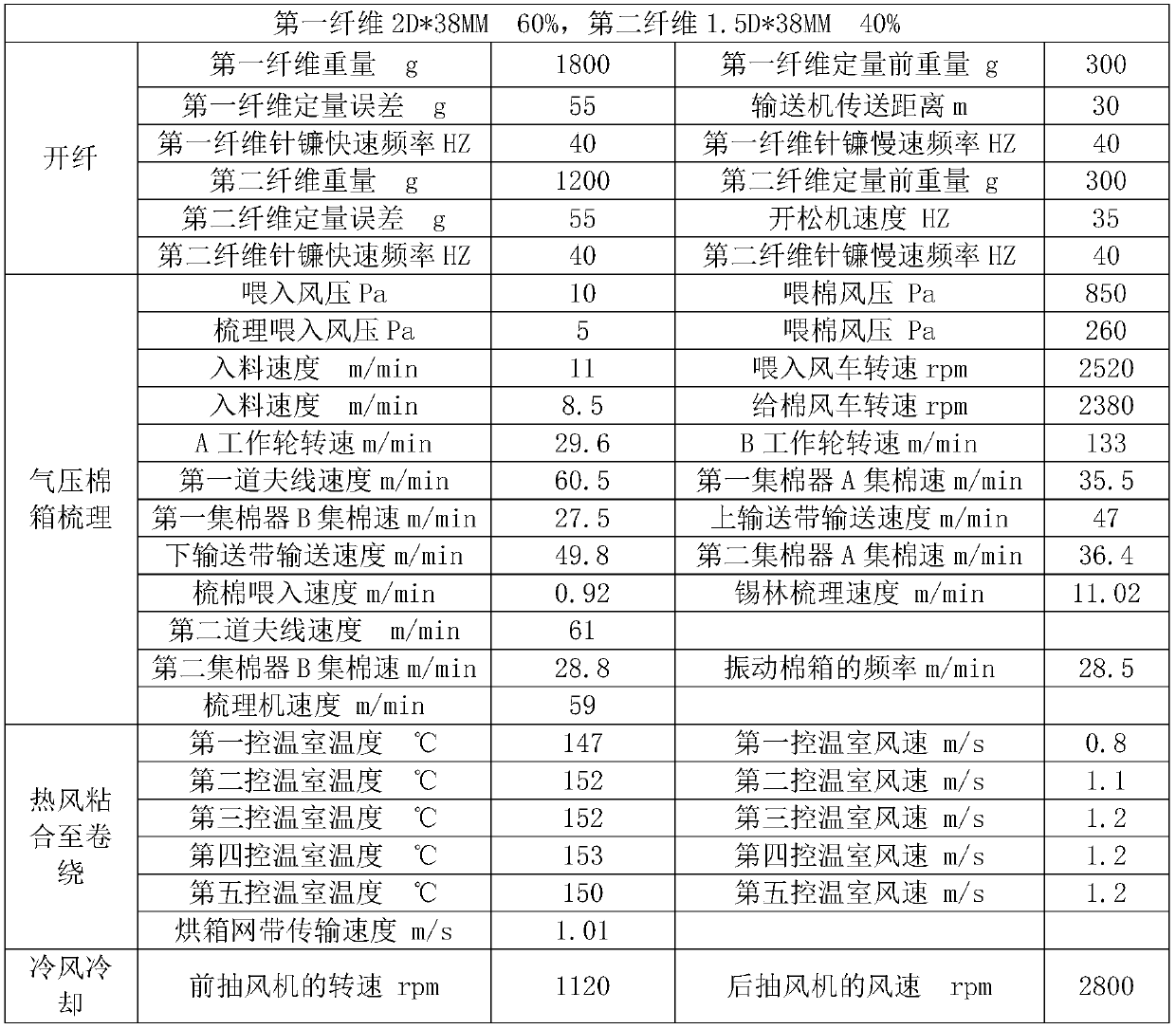

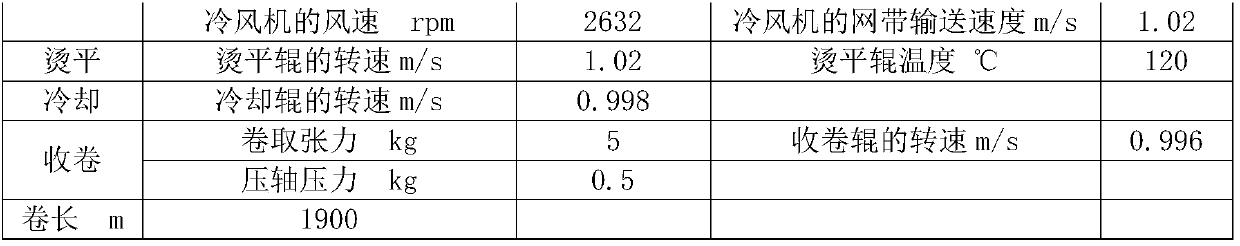

[0023] As shown in Table 1, the first fiber with a fiber fineness of 2D and the second fiber with a fiber fineness of 1.5D are selected as the textile fibers of the fluffy layer of the bottom layer of the hot air and water repellent cloth. The length of the first fiber is 38mm, and the second fiber The length is also 38mm. The first fiber is put into the first bale opener, and the second fiber is put into the second bale opener. The weight proportion of the first fiber and the second fiber is set as 60%-70%:30%-40%. Add the first fiber 1800g in the first bale opener in the present embodiment, add the second fiber 1200g in the second bale opener. The weight of the first fiber before quantification was 300 g, and the weight of the second fiber before quantification was 300 g. The weight error of the first fiber was 55 g, and the weight error of the second fiber was 55 g.

[0024] The process for preparing the fluffy cloth includes: after opening, cotton blending, carding, hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com