Heat preservation flocculus material, preparing method of heat preservation flocculus material and heat preservation product

A technology for thermal insulation products and flakes, which is applied in the directions of loose filling materials, layered products, textiles and papermaking, etc., and can solve the problems of agglomeration, entanglement, bulkiness, compression resilience, poor thermal insulation, and poor washing resistance of thermal insulation filling materials. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Preparation method of thermal insulation flake material

[0075] Embodiments of the present invention provide a method for preparing the above thermal insulation flake material, which includes:

[0076] applying spherical fiber aggregates on the first fiber monoweb;

[0077] At least the second monoweb is composited to the first monoweb to which the spherical fiber assembly is applied.

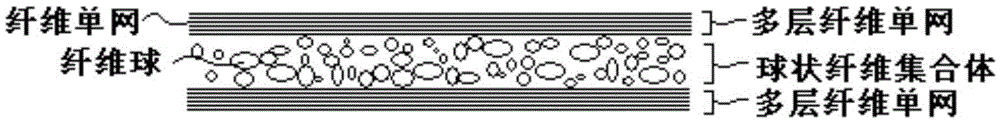

[0078] The preparation method of the thermal insulation batt material in the embodiment of the present invention comprises applying a spherical fiber assembly on one fiber single net (including multi-layer fiber single net), and then compounding another fiber single net (including multi-layer fiber single net) The step on the spherical fiber aggregate can form a structure in which the spherical fiber aggregate is sandwiched between two adjacent fiber single nets.

[0079] Specifically, a multi-layer fiber single net can be laid with a cross-lapper (the fiber single net on the top la...

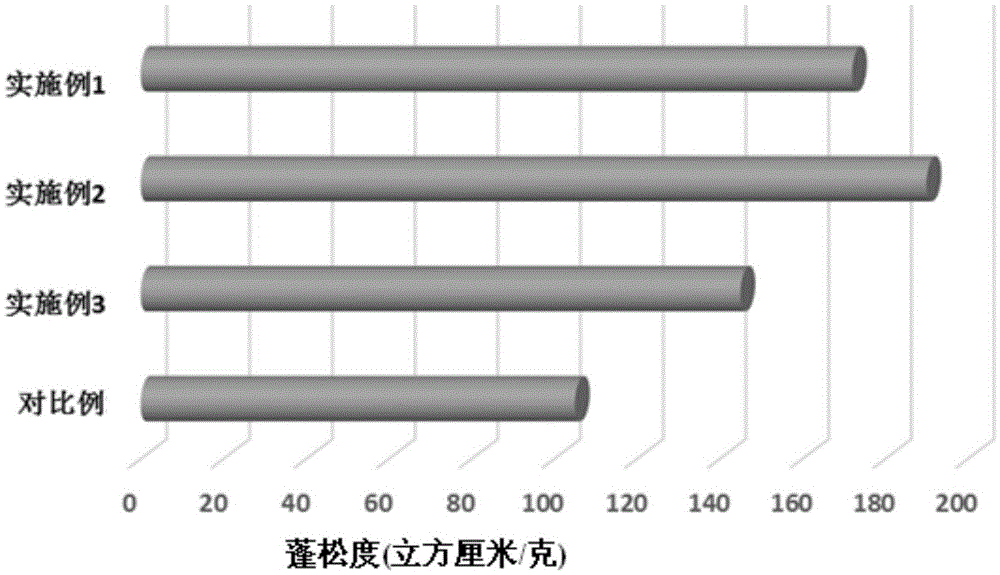

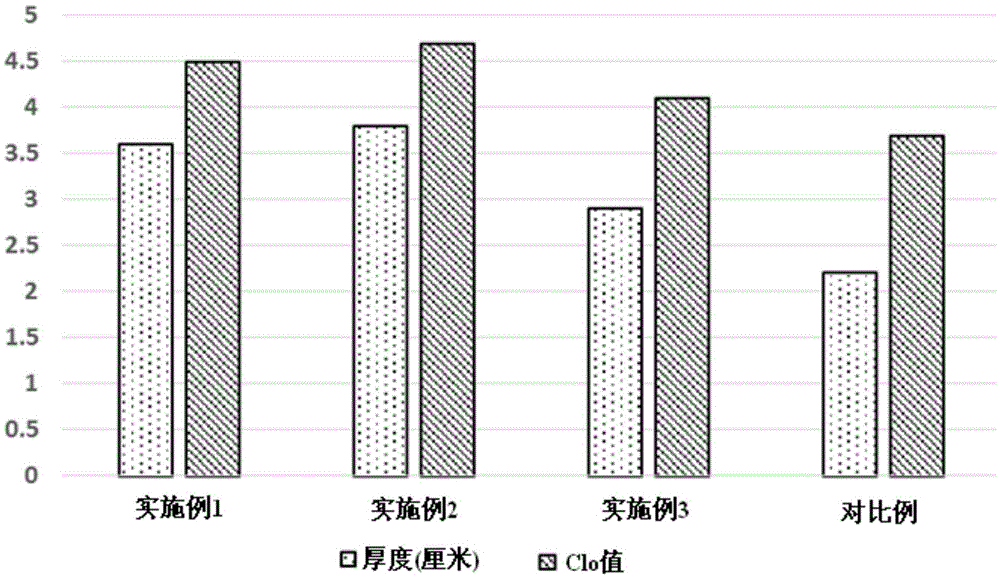

Embodiment 1

[0120] Get the low-melt fiber 1 of 1.5kg, the non-low-melt fiber 1 of 3.5kg, the non-low-melt fiber 2 of 5kg, through mixing-opening-carding-cross-lapping (it is obtained from Jiangsu Yingyang Nonwoven Machinery Co., Ltd. The scx26 type glued cotton production line carried out) forms two multi-layer fiber single nets with a grammage of 50gsm.

[0121] Take 2kg of low-melting fiber 1 and 8kg of non-low-melting fiber 2, and prepare it into fibers with a particle size of 3 mm to 15 mm through a ball forming machine (HJZZM-100 pearl cotton machine, obtained from Kunshan Haijin Machinery Co., Ltd.) Ball, as a collection of spherical fibers.

[0122] The spherical fiber assembly is evenly spread on a multi-layer fiber single net according to a grammage of 100 gsm, and then covered with another multi-layer fiber single net.

[0123] Spray glue 1 on the outer surface of the material, and the spraying amount ensures that the solid content of glue 1 is 6gsm.

[0124] Carry out thermal...

Embodiment 2

[0126] Get the low-melt fiber 2 of 1.5kg, the non-low-melt fiber 3 of 3.5kg, the non-low-melt fiber 2 of 5kg, by mixing-opening-carding-cross-lapping (it is obtained from Jiangsu Yingyang Nonwoven Machinery Co., Ltd. The scx26 type glue-sprayed cotton production line carries out) the process of forming two grammages is the multi-layer fiber single network of 20gsm.

[0127] Take 1kg of low-melting fiber 2 and 9kg of non-low-melting fiber 4, and prepare it into fibers with a particle size of 3 mm to 15 mm through a ball forming machine (HJZZM-100 pearl cotton machine, obtained from Kunshan Haijin Machinery Co., Ltd.) Ball, as a collection of spherical fibers.

[0128] The spherical fiber aggregates are evenly spread on a multi-layer fiber single net according to a grammage of 160 gsm, and then another multi-layer fiber single net is covered thereon.

[0129] Spray glue 2 on the outer surface of the material, and the spraying amount ensures that the solid content of glue 2 is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com