Composite hydrogel and preparation method thereof

A technology of compounding hydrogels and polymerizing monomers, which is applied in the fields of pharmaceutical formulations, medical preparations with non-active ingredients, and pharmaceutical sciences. Simple and convenient, good antibacterial properties, good porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

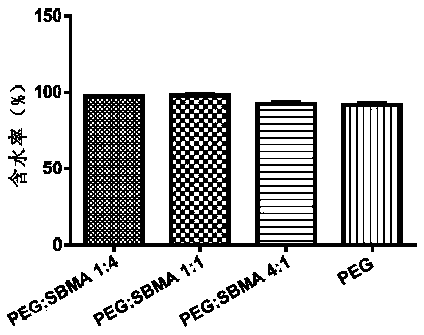

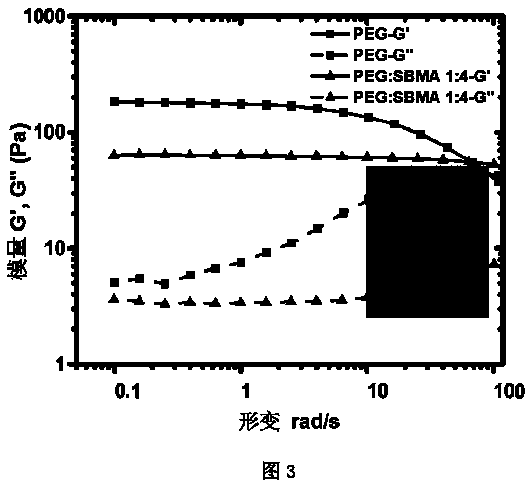

[0019] Example 1: At room temperature (preferably 25°C), take 0.2g of [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide (SBMA)H 2 C=C(CH 3 )CO 2 CH 2 CH 2 N(CH 3 ) 2 (CH 2 ) 3 SO 3 And 1.2ml of PEG monomer, add 1mL of deionized water, mix well, then add 1.4uL of crosslinking agent polyethylene glycol dimethacrylate (PEGDMA) and 7.5mg of photoinitiator Irgacure2959, the number average of the crosslinking agent The molecular weight Mn is 330, and after uniform mixing, a clear mixed solution is obtained. Subsequently, the solution containing SBMA, PEG, cross-linking agent and initiator was injected into the closed mold, and irradiated with ultraviolet light for 10 minutes to initiate free radical polymerization to prepare hydrogel PEG:SBMA4:1; then, put the mold and hydrogel together Put it into deionized water, change the water every 3 hours, record the degumming time, rinse with deionized water repeatedly after degumming and soak for 5 days.

example 2

[0020] Example 2: At room temperature (preferably 25°C), take 0.3g of SBMA and 1.1ml of PEG monomer, add 1mL of deionized water, mix well, then add 1.4uL of crosslinker PEGDMA and 7.5mg of photoinitiator Irgacure2959, the crosslinker The number-average molecular weight Mn of the linking agent is 550. After uniform mixing, a clear mixed solution is obtained; then, the solution containing SBMA, PEG, cross-linking agent and initiator is injected into a closed mold, and irradiated by ultraviolet light for 20 minutes to initiate free radical polymerization. Hydrogel PEG:SBMA2:1; Then, put the mold and hydrogel into deionized water together, change the water every 3 hours for the first two days, and then change the water twice a day, record the degumming time, and use deionized water after degumming Water was repeatedly rinsed and soaked for 5 days.

example 3

[0021] Example 3: At room temperature (preferably 25°C), take 0.5g of SBMA and 0.9ml of PEG monomer, add 1mL of deionized water, mix well, then add 1.4uL of cross-linking agent PEGDMA and 7.5mg of photoinitiator Irgacure2959, after mixing evenly , the number-average molecular weight Mn of the cross-linking agent is 2000, and a clear mixed solution is obtained; subsequently, the solution containing SBMA, PEG, cross-linking agent and initiator is injected into a closed mold, irradiated by ultraviolet light for 40min, and the free radical polymerization is initiated to obtain Hydrogel PEG:SBMA1:1; Then, put the mold and hydrogel into deionized water together, change the water every 3 hours, record the degumming time, after degumming, rinse repeatedly with deionized water and soak for 5 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com