Textile finishing liquid adopting stamping method, and finishing technology thereof

A technology of fabric finishing and patterning, which is applied in the treatment of textile materials, partial treatment of textile materials, fiber treatment, etc. It can solve the problems of short fragrance retention time, water pollution, high production cost, etc., achieve high raw material utilization rate and improve production Efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for fabric fragrance finishing by knocking stamps, including the following steps: 1) preparation of finishing liquid, preparing the following finishing liquid (both in mass percentage): Jieyu Rose microcapsules (purchased Tianjin Shuangma Flavor and Fragrance New Technology Co., Ltd.) 0.005%, crosslinking agent AF6100 (purchased from Hurt International Group Co., Ltd.) 0.1%, LYOPRINTPT-RV thickener (Huntsman Co., Ltd.) 1%, water 49 %, methyl siloxane paste (methyl siloxane and water are mixed at a ratio of 3:1) 49.895%; wherein the preparation method of methyl siloxane paste is to use methyl siloxane as raw material and water Mix, then add nonionic surfactant in the mixed solution, and high-speed emulsification under high-speed emulsifier to obtain methyl silicone paste, described nonionic surfactant is fatty alcohol polyoxyethylene ether, and its addition is 1% of the total weight of methylcyclopentasiloxane and water.

[0057] 2) Put...

Embodiment 2

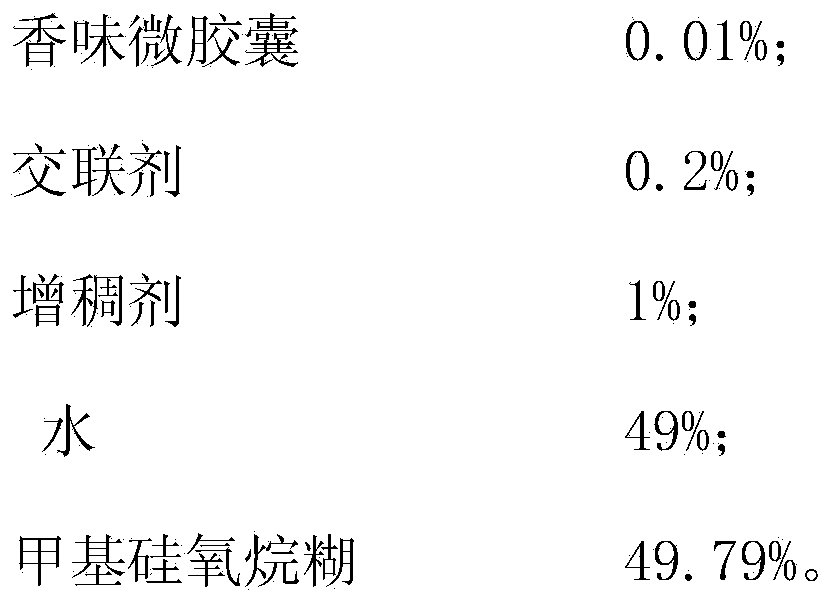

[0067] This embodiment provides a method for fabric fragrance finishing by knocking stamps, including the following steps: 1) preparation of finishing liquid, preparing the following finishing liquid (both in mass percentage): Jieyu Rose microcapsules (purchased Tianjin Shuangma Flavor and Fragrance New Technology Co., Ltd.) 0.01%, crosslinking agent AF6100 (purchased from Hurt International Group Co., Ltd.) 0.2%, LYOPRINTPT-RV thickener (Huntsman Co., Ltd.) 1%, water 49 %, methyl siloxane paste (methyl siloxane and water are mixed at a ratio of 3:1) 49.79%; wherein the preparation method of methyl siloxane paste is to use methyl siloxane as raw material and water Mix, then add nonionic surfactant in the mixed solution, and high-speed emulsification under high-speed emulsifier to obtain methyl silicone paste, described nonionic surfactant is fatty alcohol polyoxyethylene ether, and its addition is 1.5% of the total weight of methylcyclopentasiloxane and water.

[0068] 2) Put...

Embodiment 3

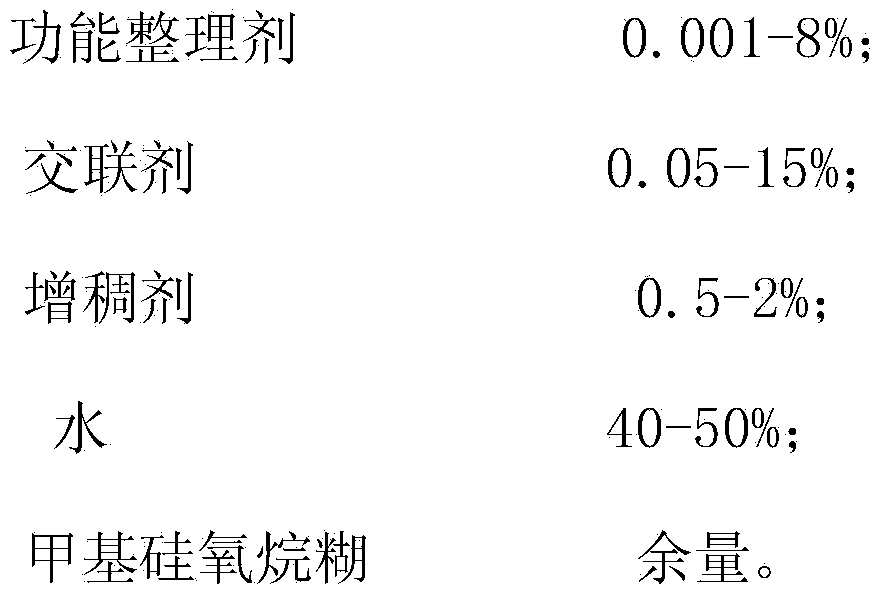

[0078]This embodiment provides a kind of method that utilizes the stamping method to carry out the aromatic finishing of fabric, comprises the following steps: 1) the preparation of finishing liquid, prepares the finishing liquid of following ratio (both are mass percent): aromatic microcapsule finishing agent (purchased Yu Tuona Chemical) 1%, crosslinking agent AF6100 (purchased from Hurt International Group Co., Ltd.) 2%, LYOPRINTPT-RV thickener (Huntsman Co., Ltd.) 0.5%, water 40%, methyl siloxane Paste (mixed with methylsiloxane and water at a ratio of 3:1) 56.5%; the preparation method of methylsiloxane paste is to mix methylsiloxane as raw material with water, and then in the mixed solution Add a nonionic surfactant, and emulsify at a high speed under a high-speed emulsifier to obtain a methyl silicone paste. The nonionic surfactant is fatty alcohol polyoxyethylene ether, and its addition is methylcyclopentasiloxane and 2% of the total weight of water.

[0079] Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com