Hose capable of being flattened and manufacturing method thereof

A manufacturing method and hose technology, which is applied to hoses, pipes, textiles and papermaking, etc., can solve the problems of increasing the thickness of the reinforcement layer, the difficulty of coating the inner and outer rubber layers, the decrease in softness, and the difficulty in forming the hose, etc., to achieve Convenient coiled or folded storage, good softness, and the effect of improving the delivery flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

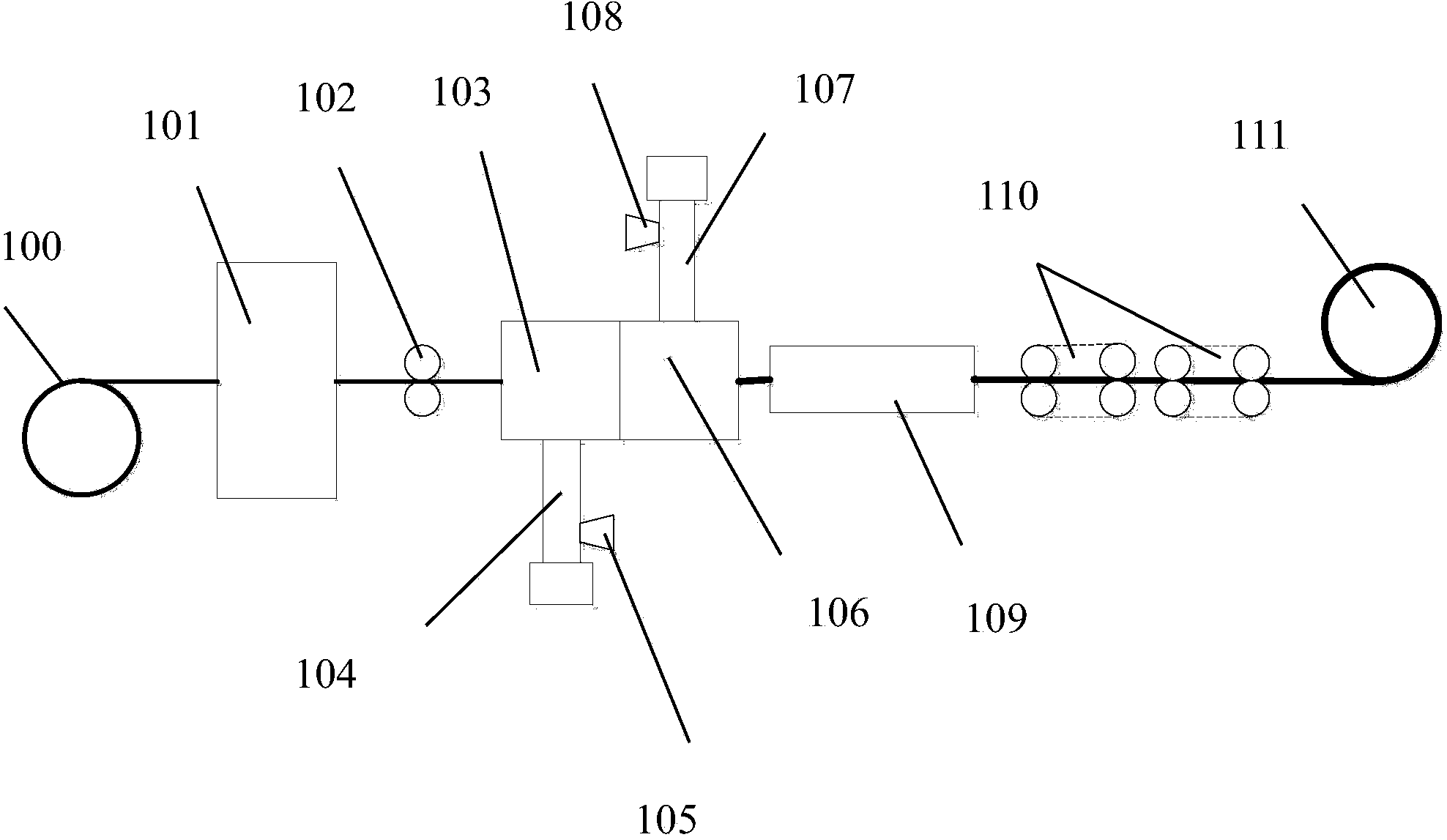

[0013] The present invention is described in detail below with reference to the accompanying drawings, in which like reference numerals denote like parts. In order to achieve the above purpose, the following technical solutions are adopted:

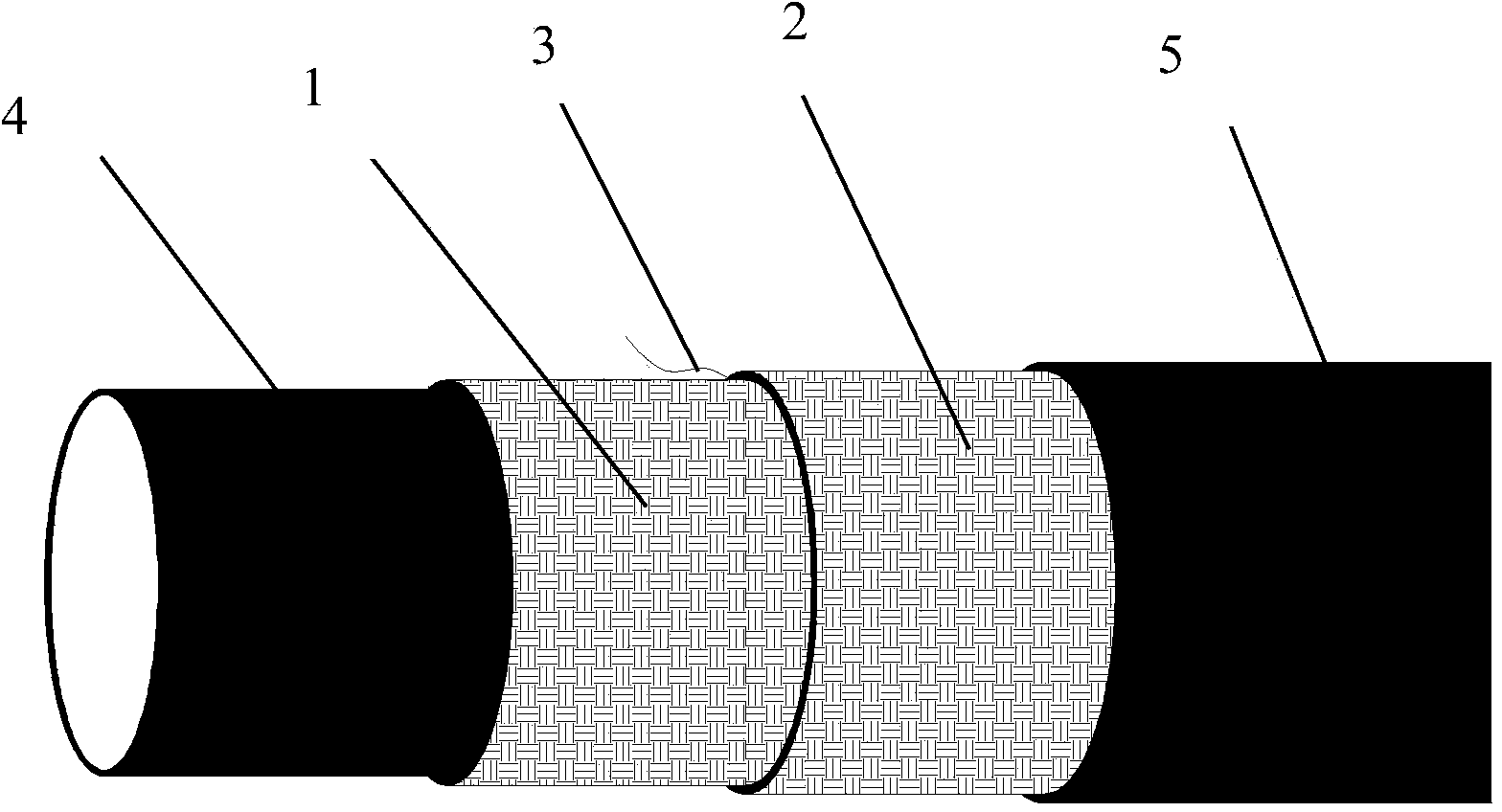

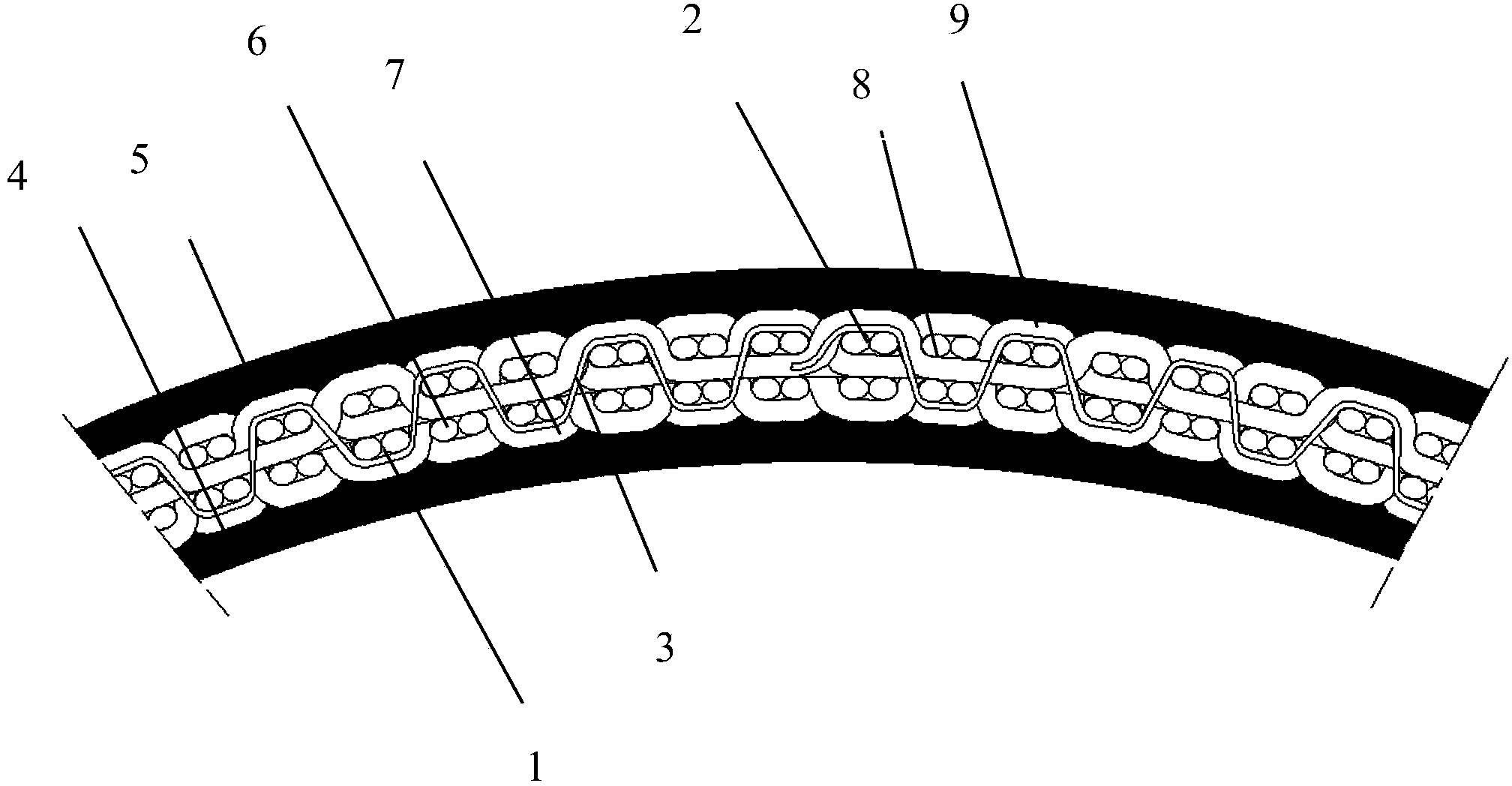

[0014] figure 1 A schematic structural view of an embodiment of the flattenable hose of the present invention is shown. figure 2 for figure 1 A partial cutaway view of a flattenable hose in . Such as Figure 1-2 As shown, the flattenable hose includes, from inside to outside, an inner rubber layer 4 , an inner reinforcement layer 1 , a binding weft 3 , an outer reinforcement layer 2 and an outer rubber layer 5 .

[0015] The inner rubber layer 4 and the outer rubber layer 5 are made of thermoplastic polyurethane body material or thermoplastic polyurethane added with additives. Optionally, the inner rubber layer 4 and the outer rubber layer 5 are made of polyether thermoplastic polyurethane or polyester thermoplastic polyurethane.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com