Hub flange plate combined machining center

A combined processing and hub flange technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of inability to ensure the smoothness of the hub flange, poor machining accuracy of the hub flange, and inability to process workpieces, etc. problems, to achieve the effect of achieving simplicity, ensuring work continuity, and improving the finish of tapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

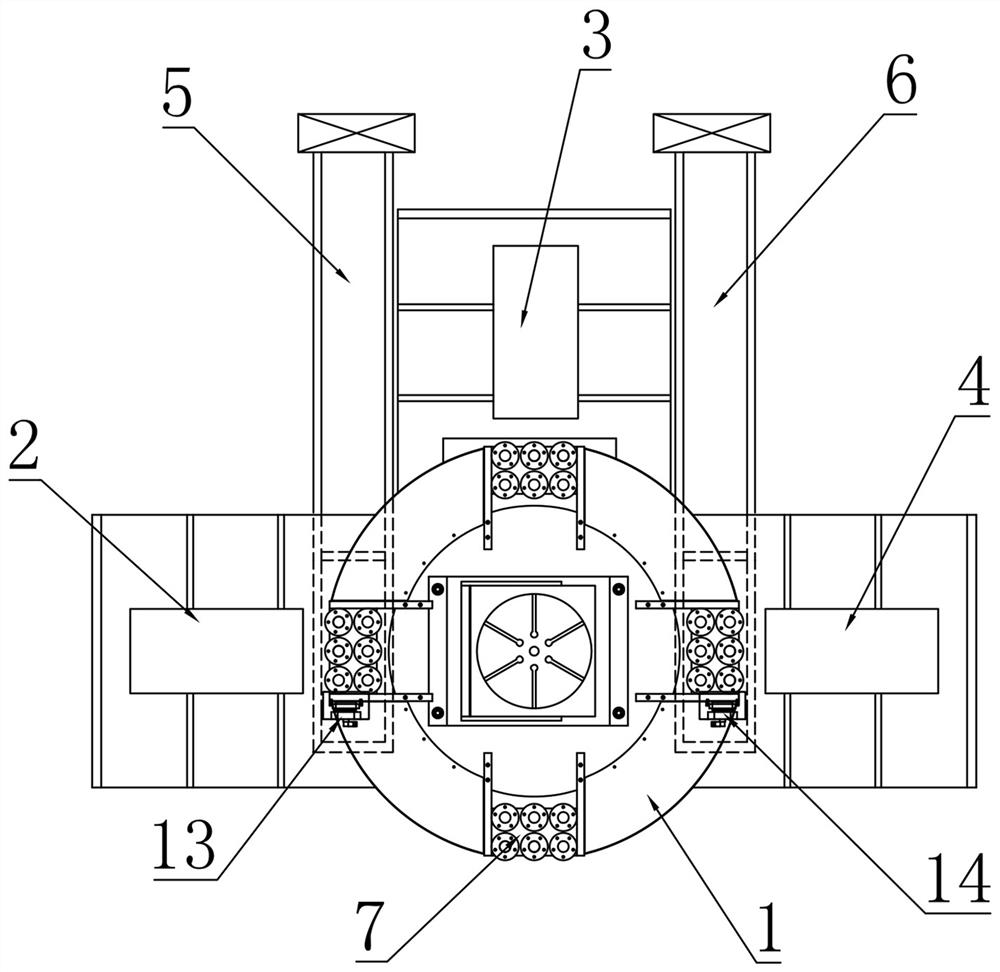

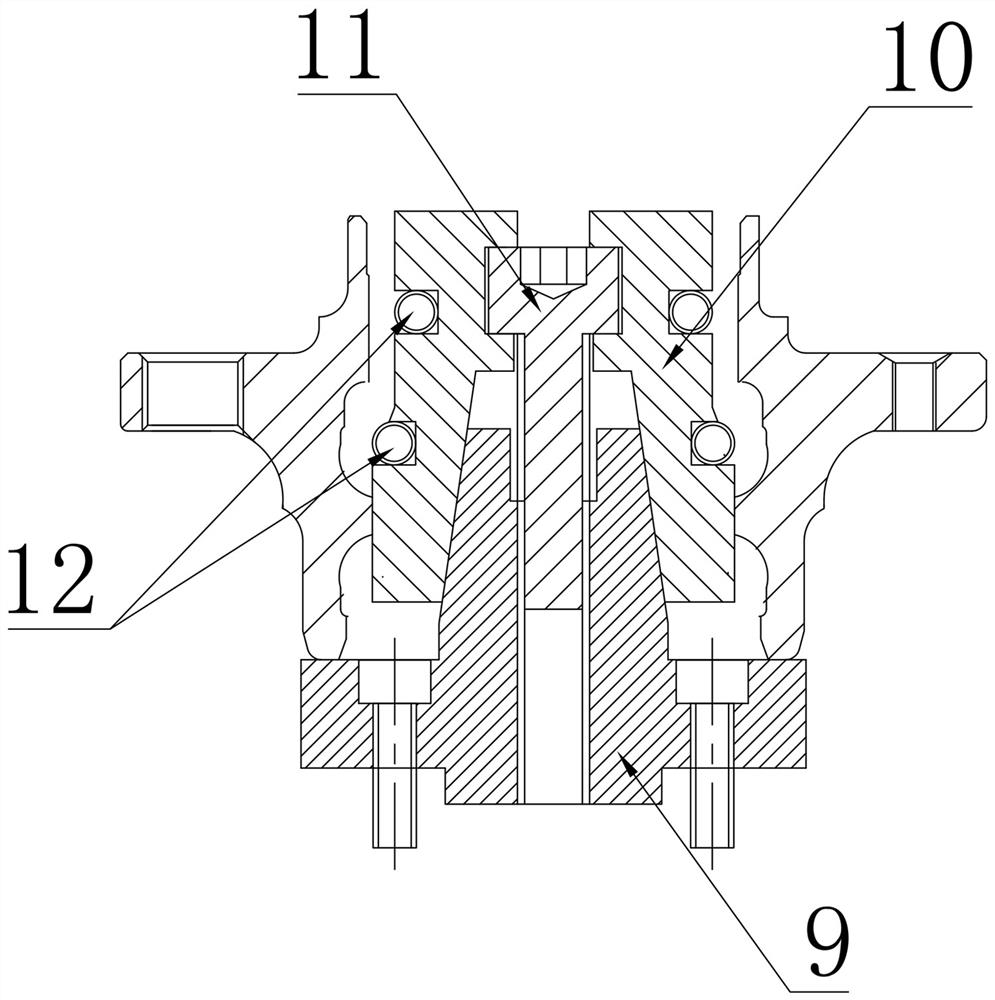

[0030] Embodiment A combined machining center for hub flanges

[0031] like figure 1 As shown, this embodiment includes a rotary table 1 , and a drilling mechanism 2 , a chamfering mechanism 3 and a tapping mechanism 4 that are circularly distributed around the rotary table 1 along the rotation direction of the rotary table 1 . When machining the hub flange, the rotary table 1 can quickly transfer the workpiece, thereby ensuring that the drilling mechanism 2, chamfering mechanism 3 and tapping mechanism 4 can respectively complete the corresponding drilling, chamfering and tapping operations on the workpiece.

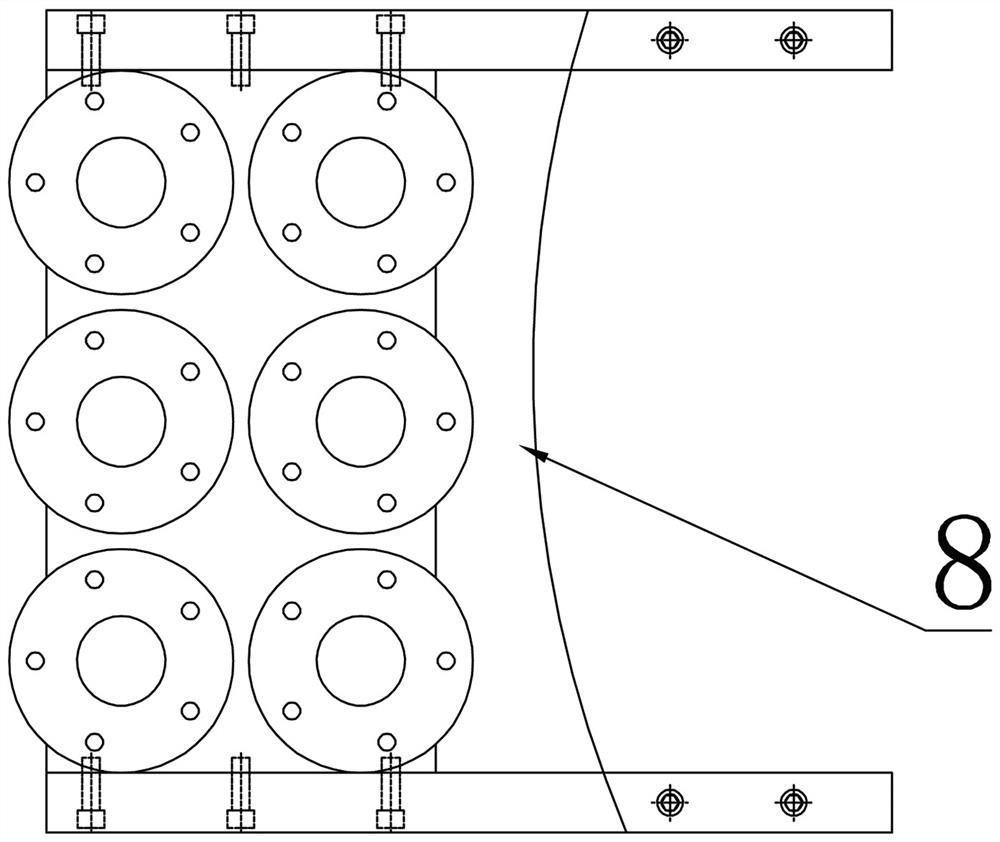

[0032] In this embodiment, a first chip removal machine 5 and a second chip removal machine 6 are respectively provided under the rotary table 1 and on both sides of the chamfering mechanism 3 . The first chip removal machine 5 is located below the working position of the drilling mechanism 2, and includes the first scraper conveyor and the first filtered water tank lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com