Tea bag packaging line and its tea bag conveying device, tea bag reversing mechanism

A technology of reversing mechanism and conveying device, which is applied in packaging, food packaging, transportation and packaging, etc. It can solve the problem that the inner bag packaging system and the outer bag packaging system cannot be directly connected, so as to ensure the continuity of work and simple structure , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

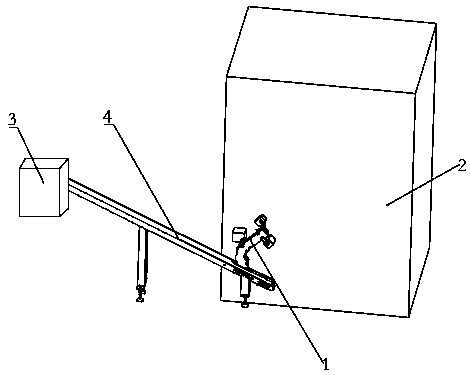

[0045] Embodiment one of the tea bag reversing mechanism of the present invention: as figure 1 As shown, the tea bag reversing mechanism 1 is mainly used between the inner bag packaging system 2 and the outer bag packaging system 3, and the "W" double bag bottom of the tea bag 5 coming out of the inner bag packaging system 2 is oriented in the same direction as the outer bag packaging system. System 3 requires teabags "W" in cases where the double capsule bottoms are oriented differently. In this embodiment, it is defined that the opening of the inner bag packaging system 2 faces the rear side, the outer bag packaging system 3 is located at the rear side of the inner bag packaging system 2, and the opening of the outer bag in the outer packaging system faces the front side, in the outer bag packaging system 3 and the tea bag reversing mechanism 1 are also connected with a conveyor belt 4, and the above-mentioned conveyor belt 4 and tea bag reversing mechanism 1 form a tea bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com