Mechanical automatic reversing valve and using method thereof

An automatic reversing and reversing valve technology, applied in mechanical equipment, multi-port valves, control valves, etc., can solve the problems of high failure rate, troublesome power supply, troublesome second wiring, etc., to achieve low failure rate and easy use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

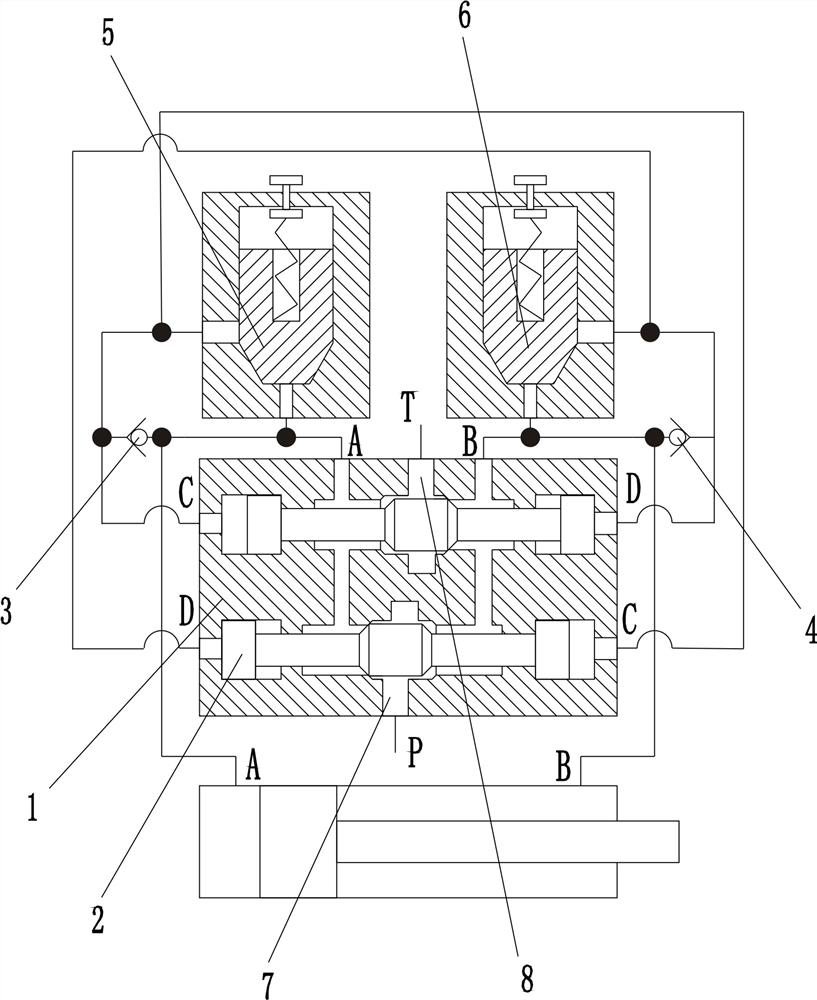

[0027] Join figure 1 An automatic mechanical valve for automatic control of the running direction of the actuator, comprising a valve body 1, valve core 2, I3 check valve, the check valve Ⅱ4, pressure regulating valve and a pressure regulating valve Ⅰ5 Ⅱ 6; the valve body 1 is provided with a hydraulic oil supply port for high-pressure oil system corresponding to communication pipe P7, corresponding to the tank in communication with the hydraulic system oil return port T8, and a piston chamber corresponding to the actuator connection port communicating A9, and performing means corresponding to the other piston chamber communicating connection port B10;

[0028] The valve body 1 equipped with the valve body cavity, the cavity is attached to the valve body for switching the connection port the A9, B10 connecting port and the oil port P7, the correspondence between the valve core return port communicating relationship T8 2; valve 1 A9 equipped with the connection port corresponding t...

Embodiment 2

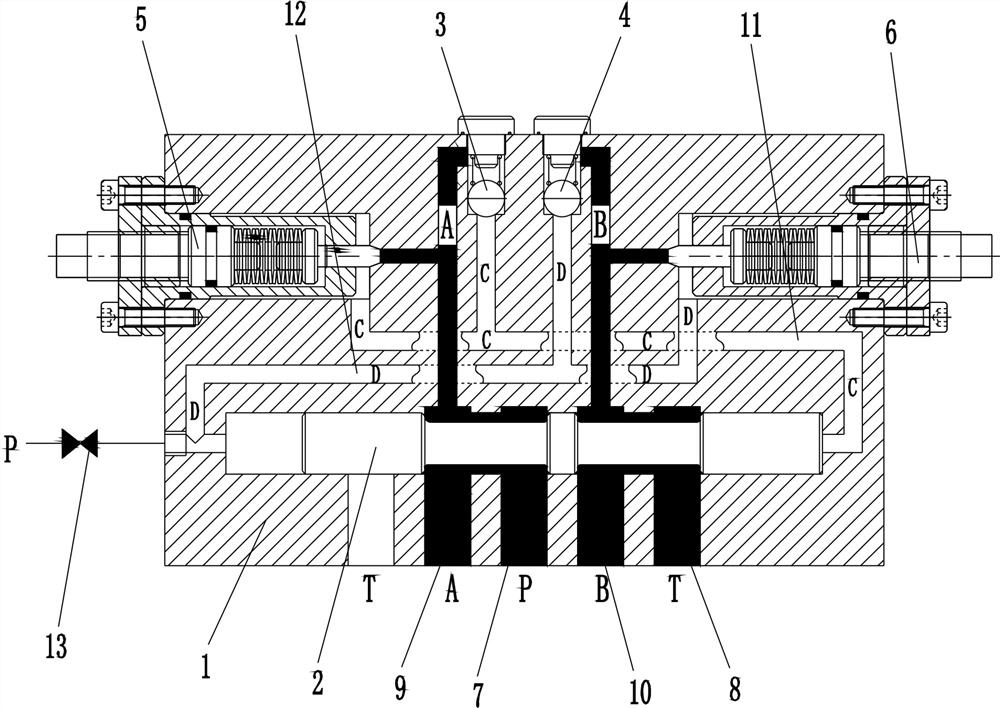

[0031] Join Figure 2 ~ 3, Mechanical automatic valve of the embodiment of the present embodiment is a further embodiment of the embodiment defining, with the first embodiment except that: the cavity is a valve body, valve stem and valve body 2 comprises a core step, the middle and both ends of the valve stem and the valve chamber is provided with a sealing sliding fit in the valve body corresponding to the step, are sequentially laid side by side in one side of the valve body cavity there is the return port T8, the A9 connection port, an oil supply port P7, and a return port connected to port T8 B10; B10 and the connecting port T8 corresponding to the return port when the connection port communicates with the oil supply port P7 communicates A9, A9 when the connection port corresponding to the return port T8 communicates with the oil supply port connection port B10 P7 communicates, simple structure easy to assemble;

[0032] The machine according to the present embodiment of the au...

Embodiment 3

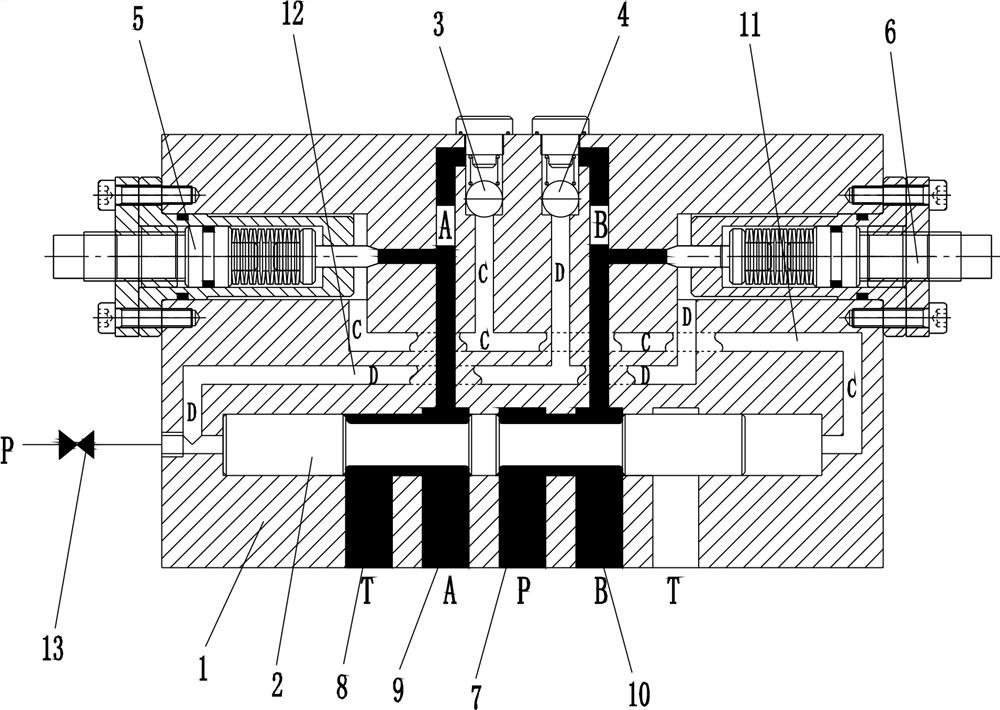

[0034] Join Figure 4 ~ 5 , Mechanical automatic valve of the embodiment of the present embodiment is a further embodiment of the embodiment defining, with the first embodiment except that: the valve body cavity is a two, respectively, the valve body and the valve chamber cavity Ⅰ ⅱ, the spool left end chamber passage ⅰ and D12 corresponding to an end of communication, and the right end corresponding to the communication passage C11, the left end of the spool chamber ⅱ communication passage C11 corresponding to an end, the right end corresponding to an end of the oil passage communicating D12; spool bore ⅰ and the valve spool bore has ⅱ core 2, the core 2 comprises a ball valve, and the valve stem step, the stem ends of the valve body and the valve body has a sealing sliding fit in a corresponding cavity step, the central stem is provided with a ball head corresponding to a respective spool chamber ⅰ valve core has a diameter greater than the diameter of the ball head between the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com