Patents

Literature

34results about How to "Packaging safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

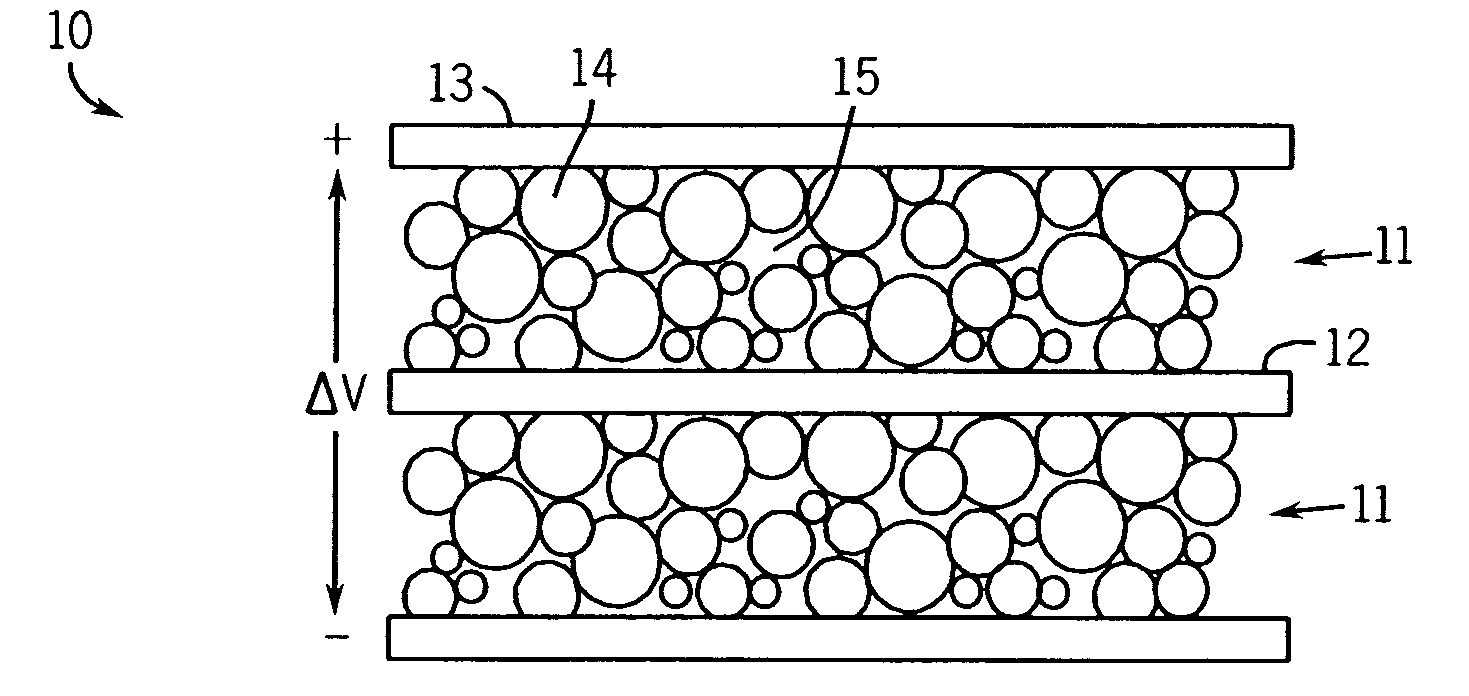

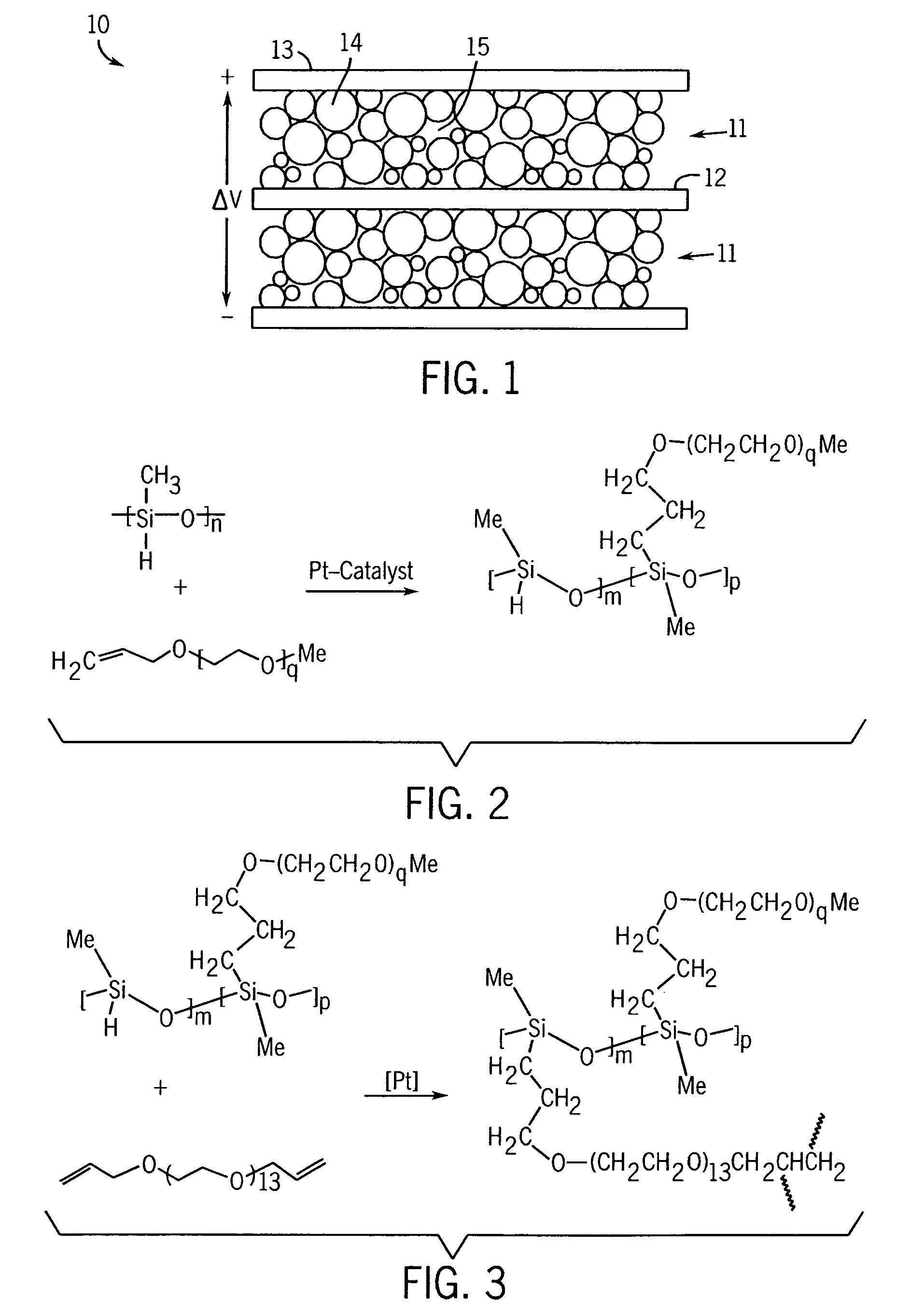

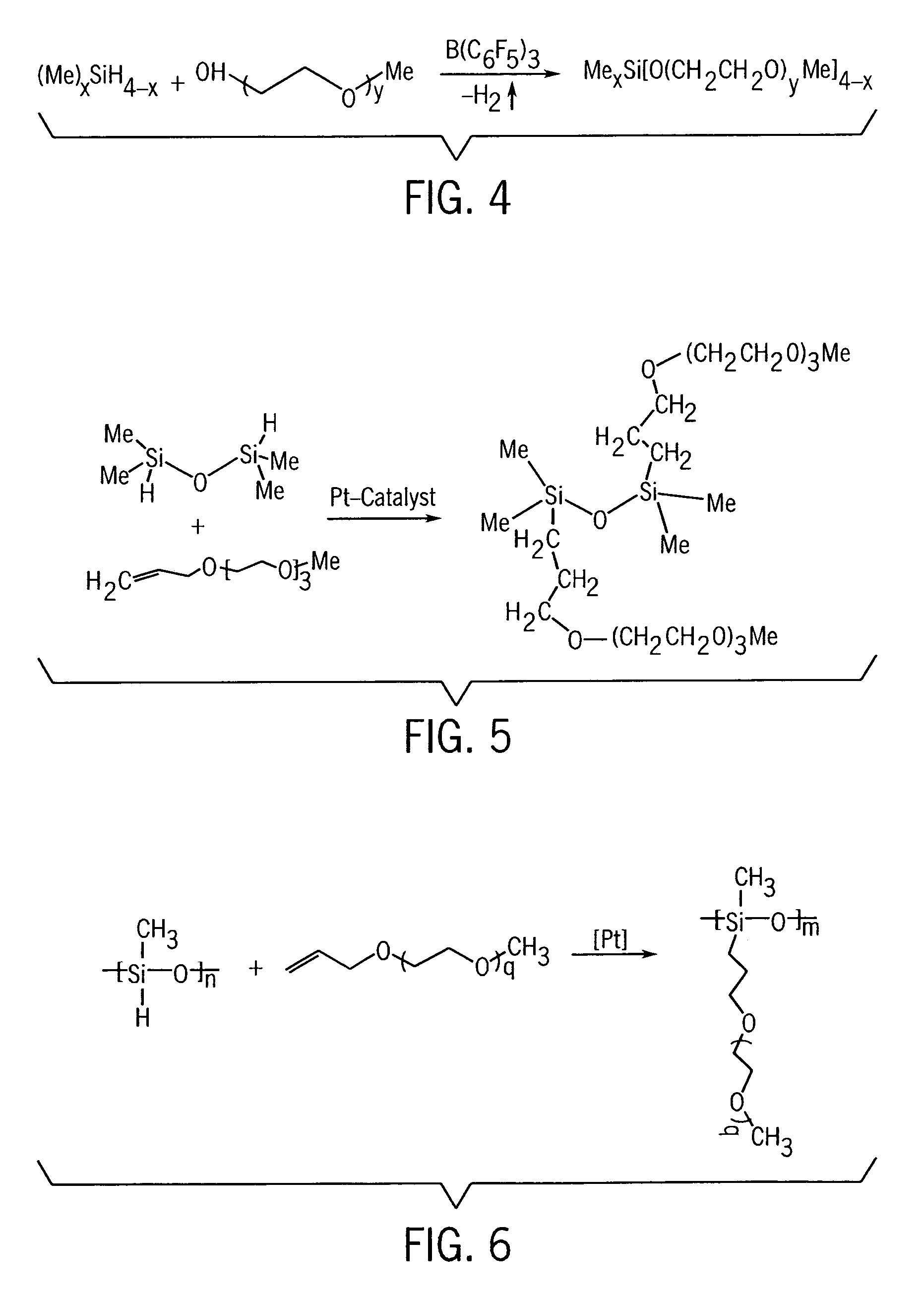

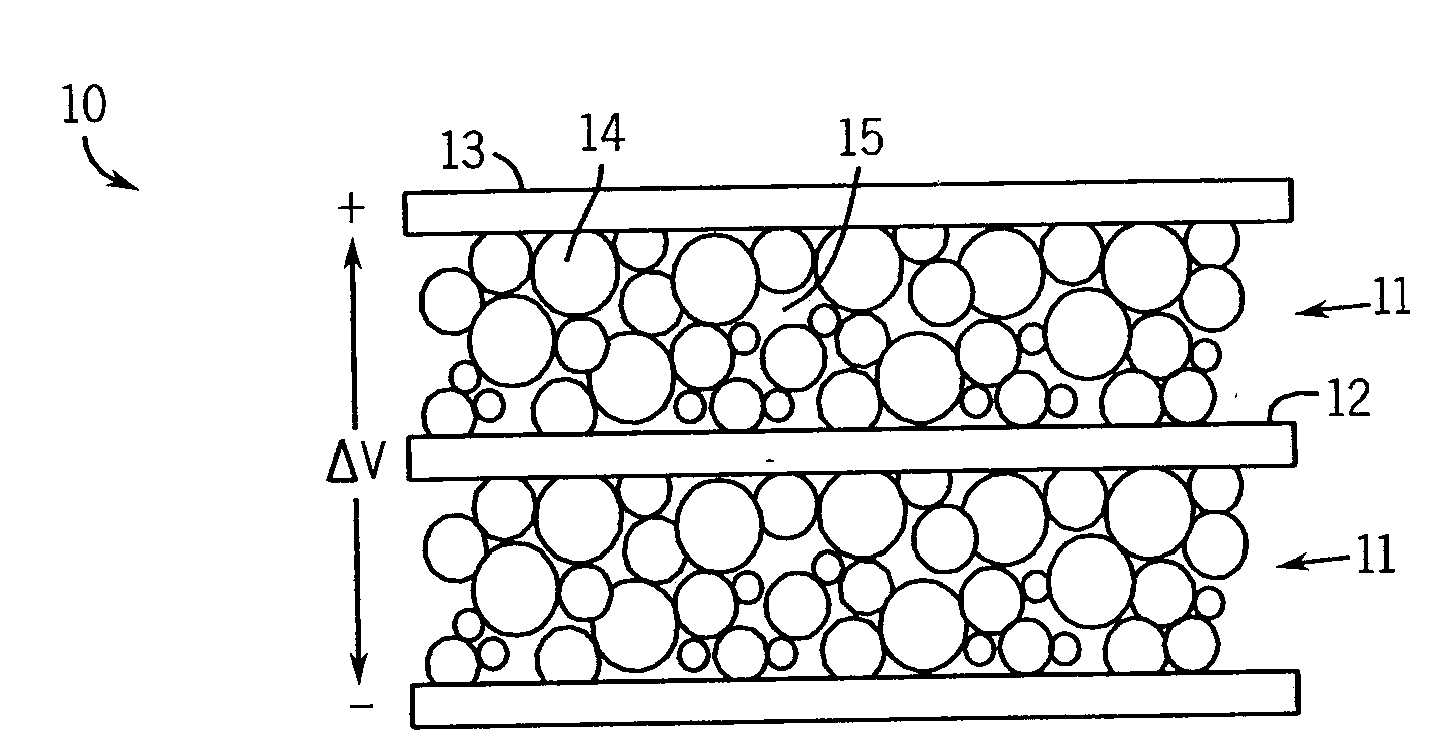

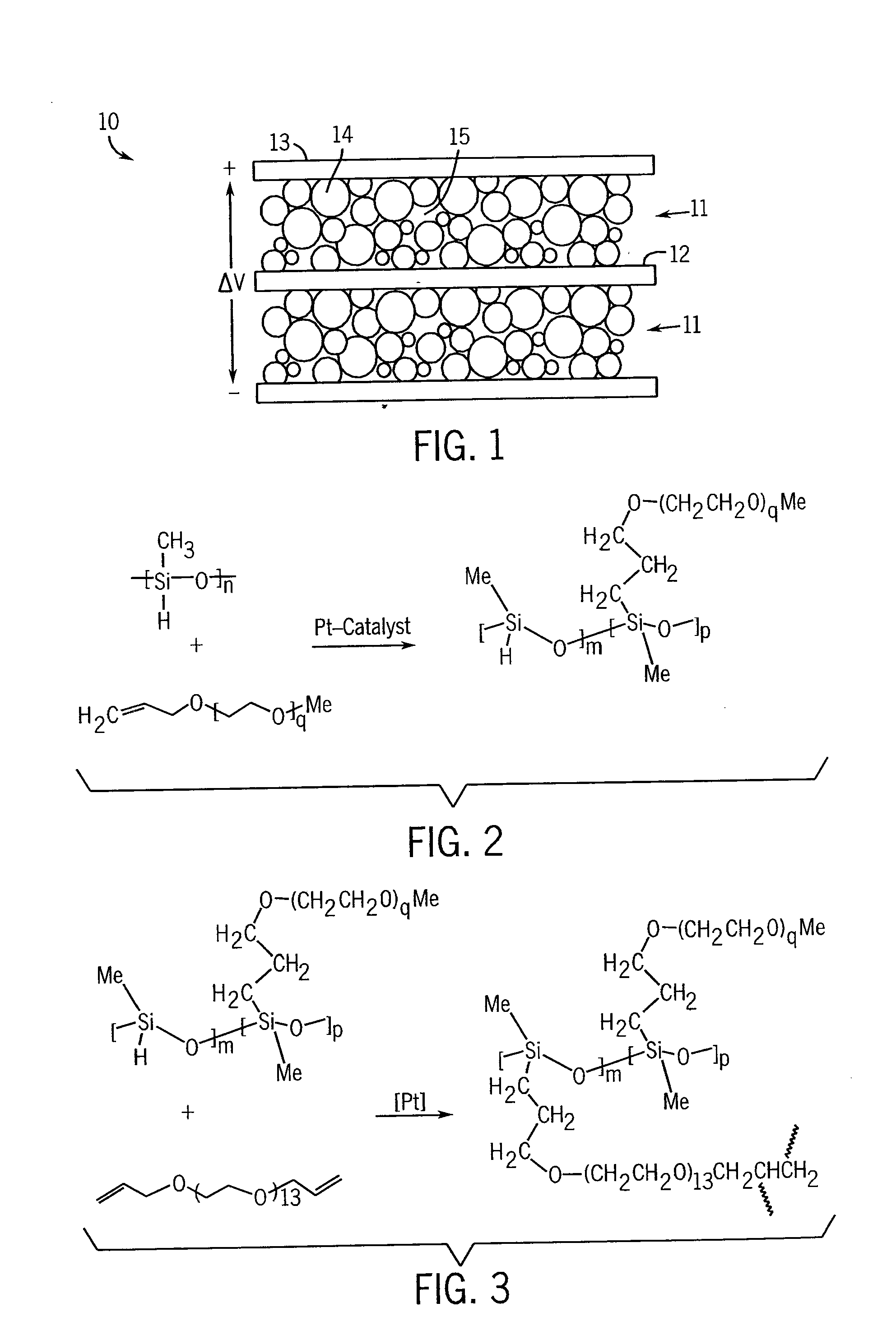

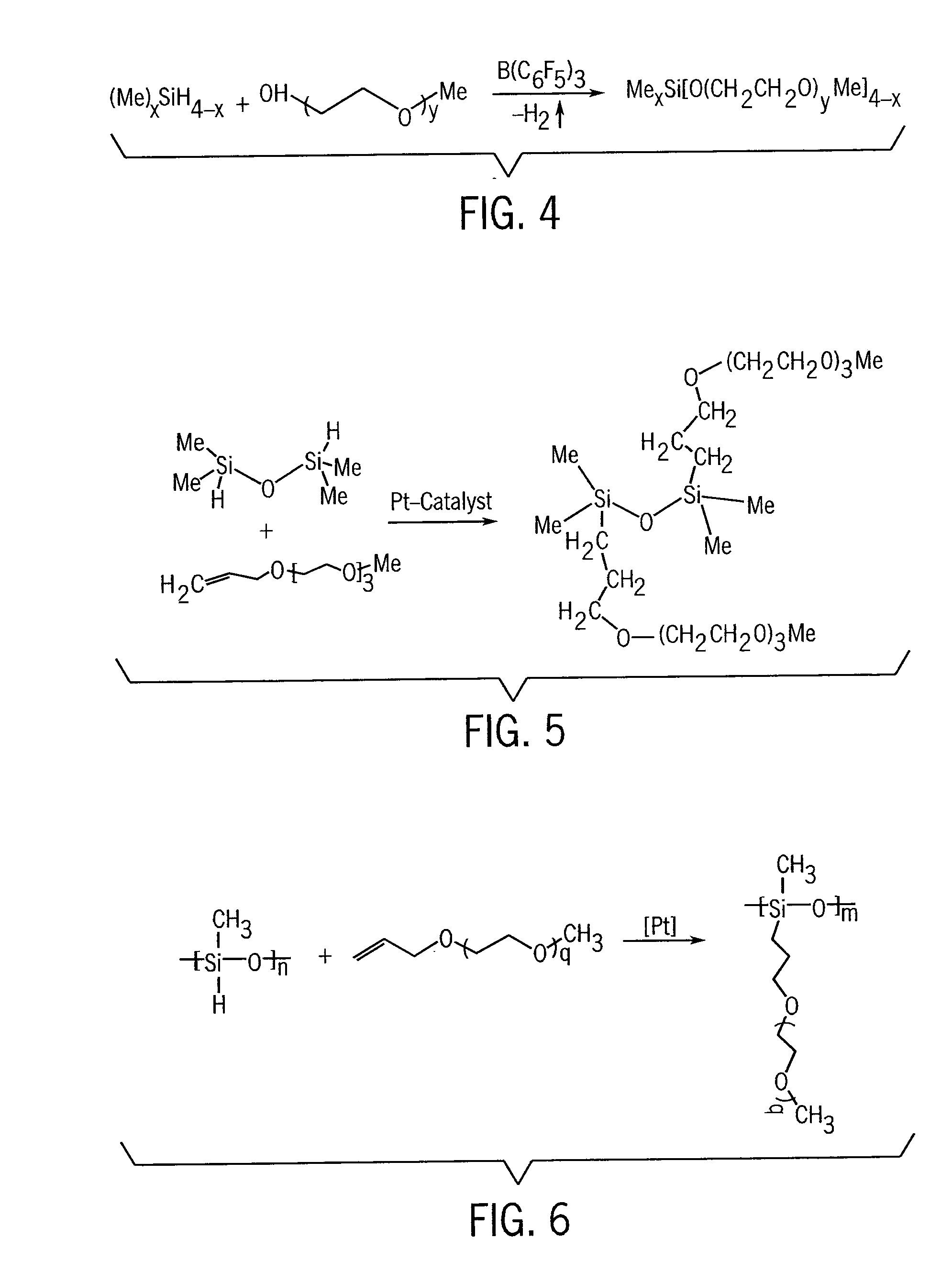

Electrochemical double-layer capacitor using organosilicon electrolytes

ActiveUS7466539B2Improve ionic conductivityHigh operating voltage and temperatureHybrid capacitor electrolytesHybrid capacitor electrodesPolymer capacitorPorous carbon

Disclosed are supercapacitors having organosilicon electrolytes, high surface area / porous electrodes, and optionally organosilicon separators. Electrodes are formed from high surface area material (such as porous carbon nanotubes or carbon nanofibers), which has been impregnated with the electrolyte. These type devices appear particularly suitable for use in electric and hybrid electric vehicles.

Owner:WISCONSIN ALUMNI RES FOUND

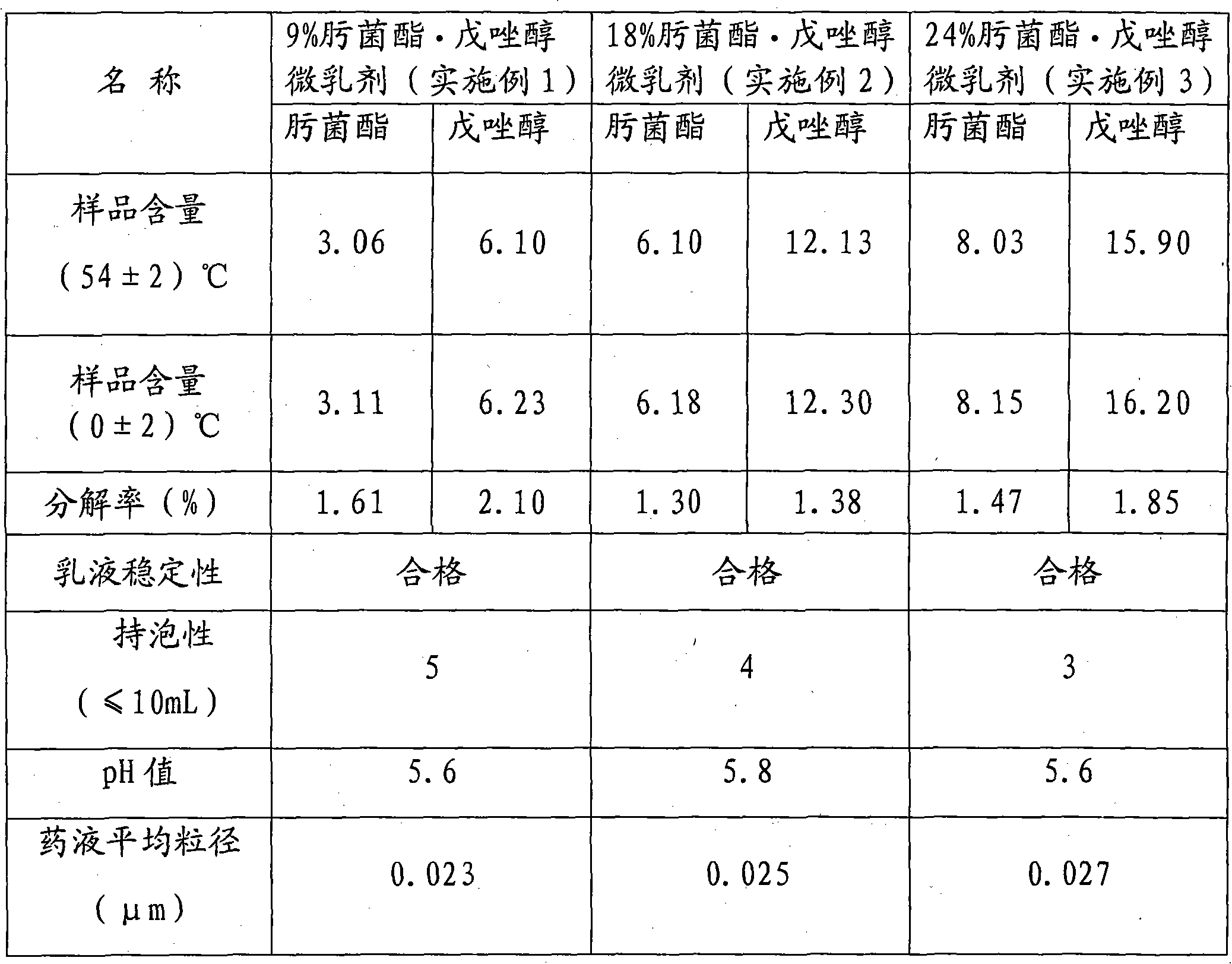

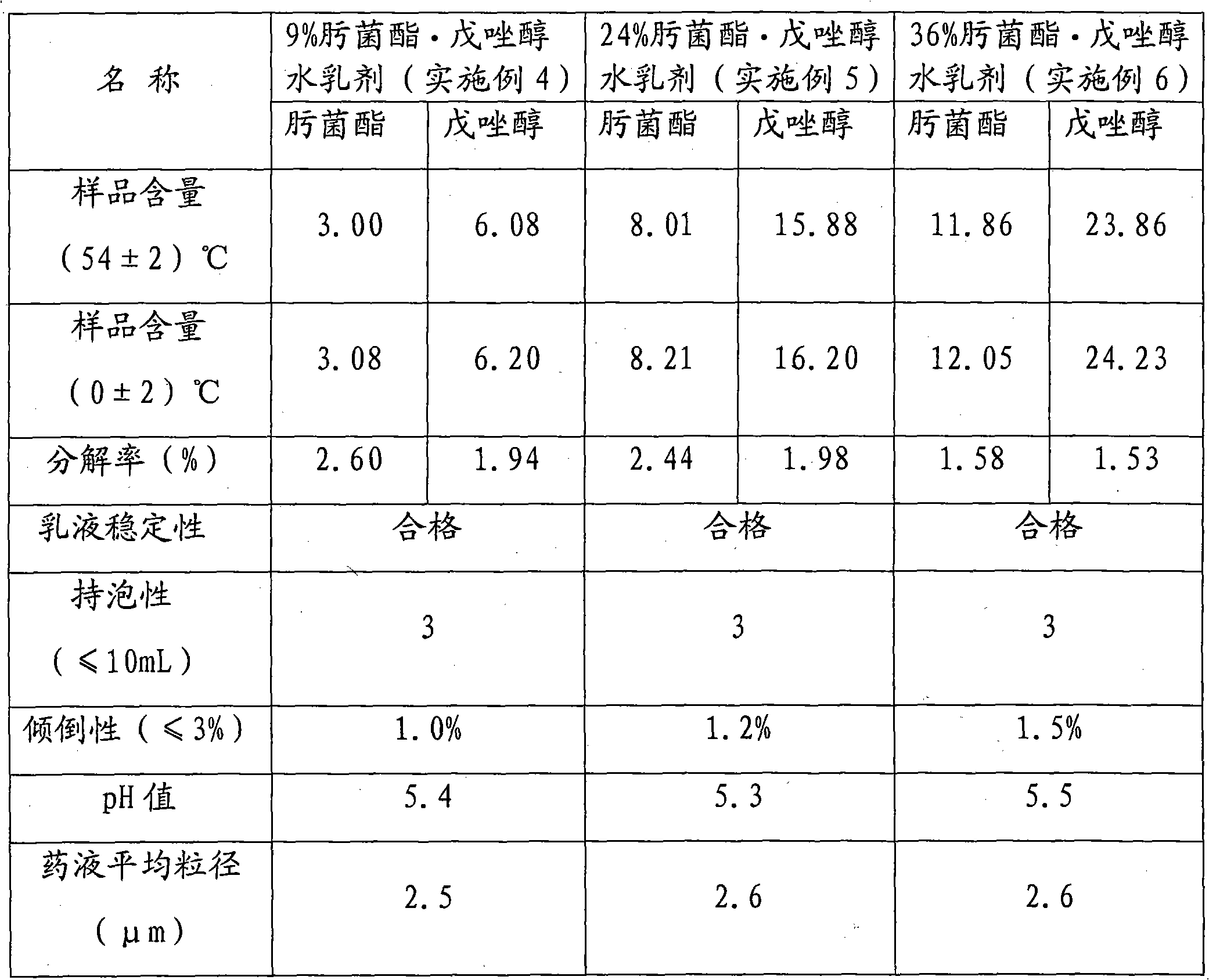

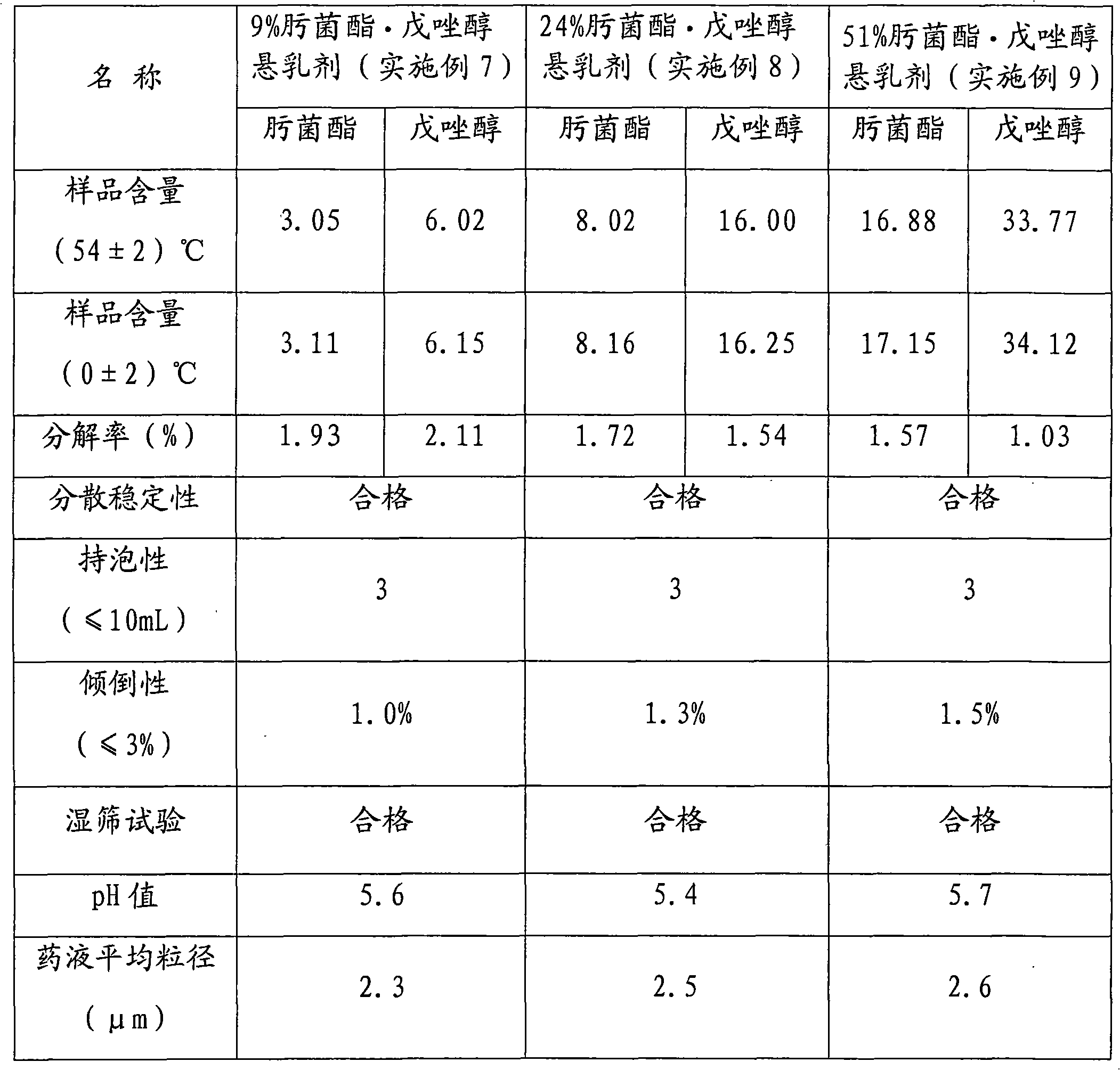

Antiseptic composition waterborne preparation and method for preparing same

InactiveCN101836635ARaw materials are cheap and easy to getPromote safe productionBiocideFungicidesEmulsionMicroemulsion

The invention discloses an antiseptic composition waterborne preparation and a method for preparing the same, and in particular relates to trifloxystrobin, a tebuconazole microemulsion, an aqueous emulsion and a suspension emulsion and a method for preparing the same. The antiseptic composition waterborne preparation comprises the following raw materials in percentage by weight: 3 to 20 percent of trifloxystrobin, 6 to 40 percent of tebuconazole, 0.5 to 20 percent of solvent, 0 to 8 percent of cosolvent, and the balance of water. By adopting different solvent combinations and processing technology according to the content of active ingredients, the method can realize the conversion among three formulations; and the waterborne preparation overcomes the defects in the conventional formulation, provides more choices for diversification of the formulations of products and meets market requirements.

Owner:SHENZHEN NOPOSION AGROCHEM

Electrochemical Double-Layer Capacitor Using Organosilicon Electrolytes

ActiveUS20080273290A1Improve ionic conductivityHigh operating voltage and temperatureHybrid capacitor electrolytesHybrid capacitor electrodesPolymer capacitorPorous carbon

Disclosed are supercapacitors having organosilicon electrolytes, high surface area / porous electrodes, and optionally organosilicon separators. Electrodes are formed from high surface area material (such as porous carbon nanotubes or carbon nanofibers), which has been impregnated with the electrolyte. These type devices appear particularly suitable for use in electric and hybrid electric vehicles.

Owner:WISCONSIN ALUMNI RES FOUND

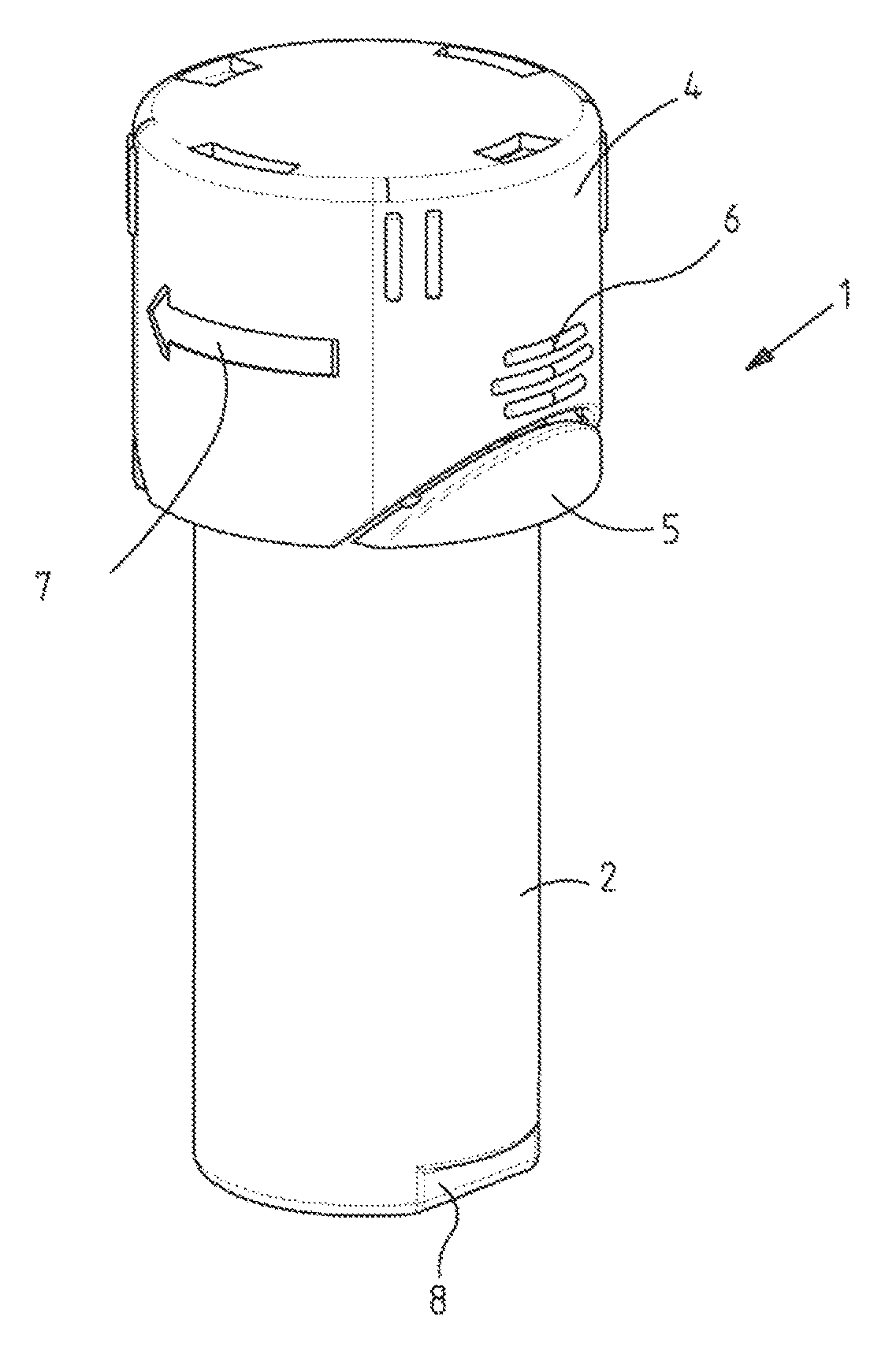

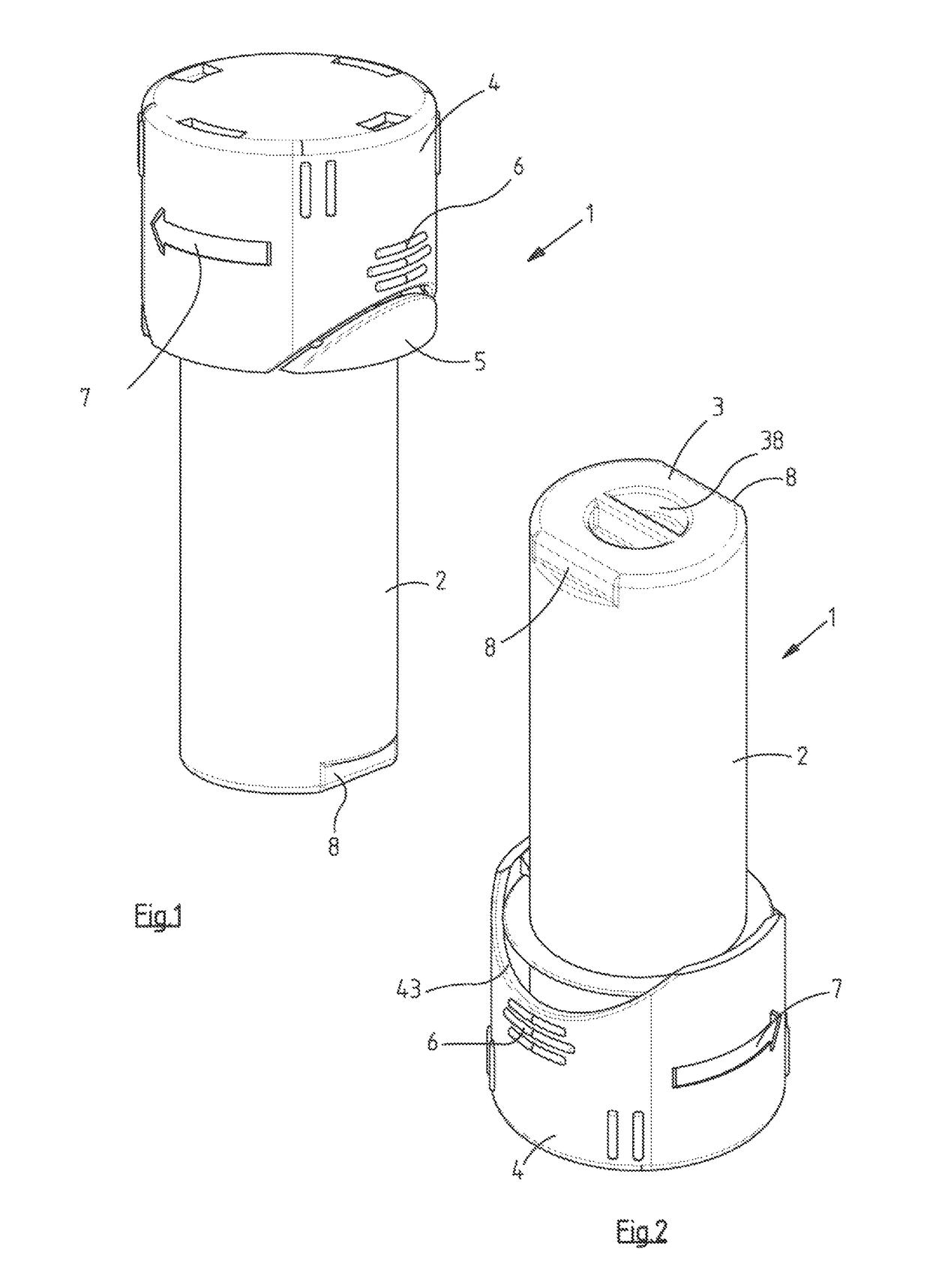

Container comprising a dispenser for goods to be packaged

InactiveUS9764888B2Low production costLow costSmall article dispensingEngineeringMechanical engineering

Owner:SANNER

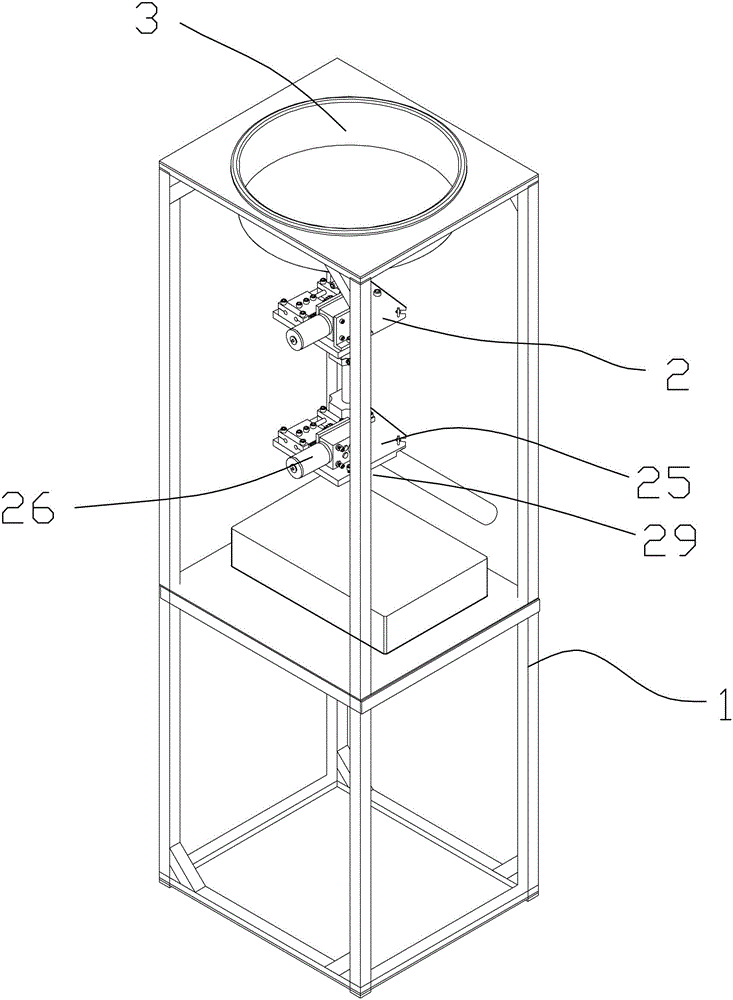

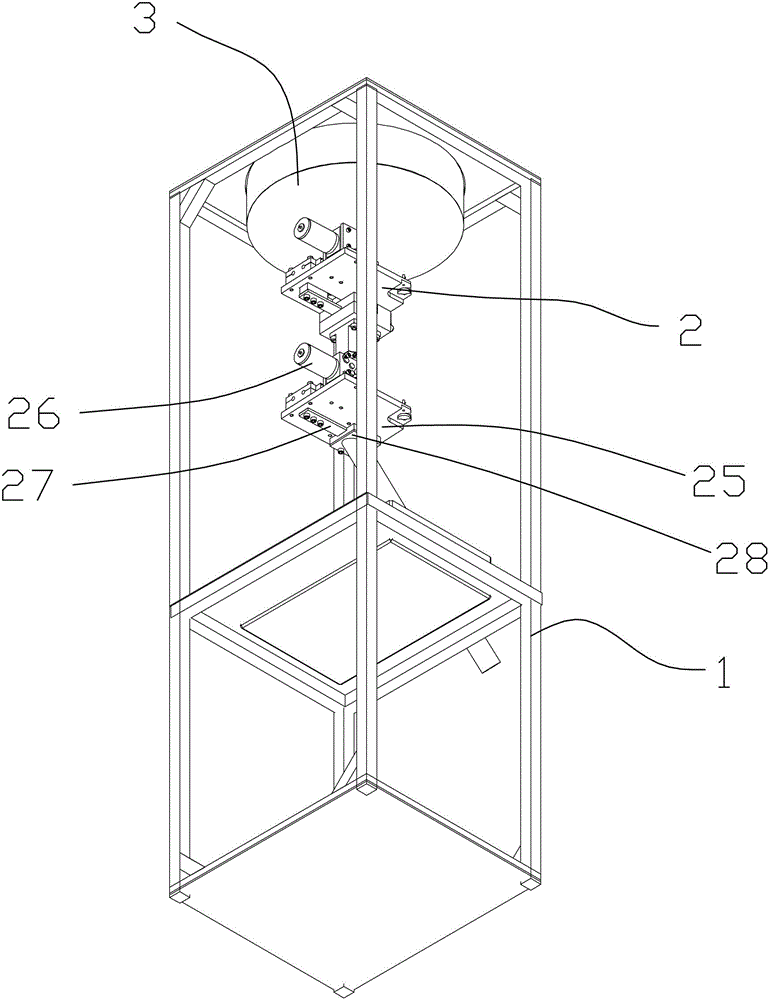

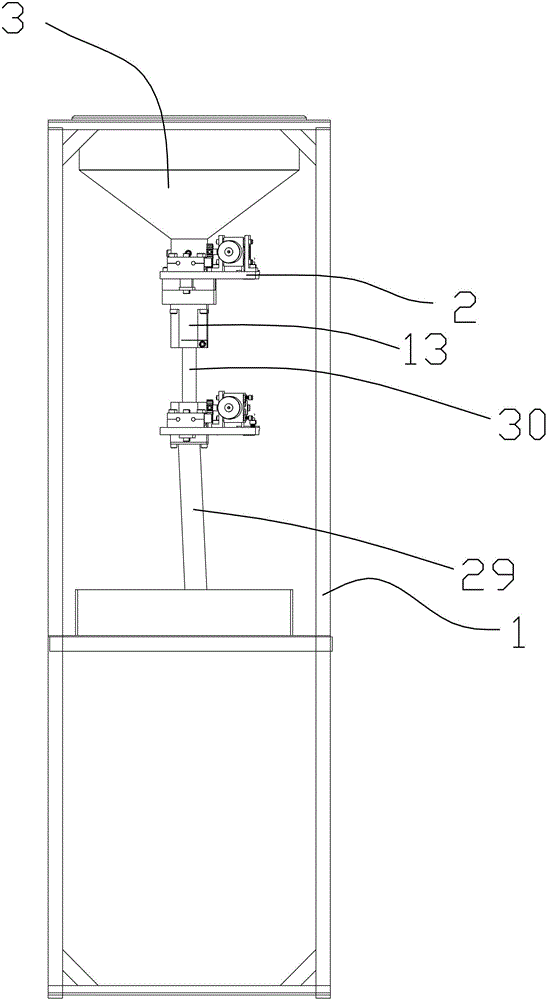

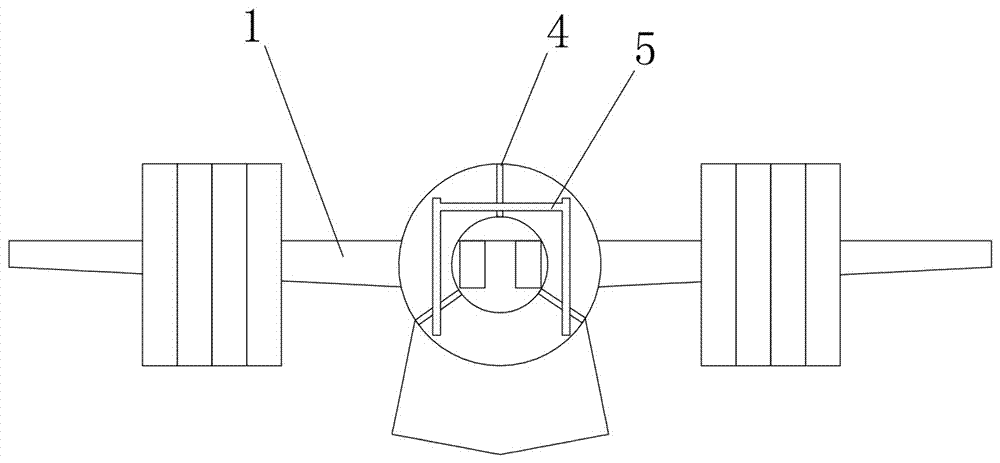

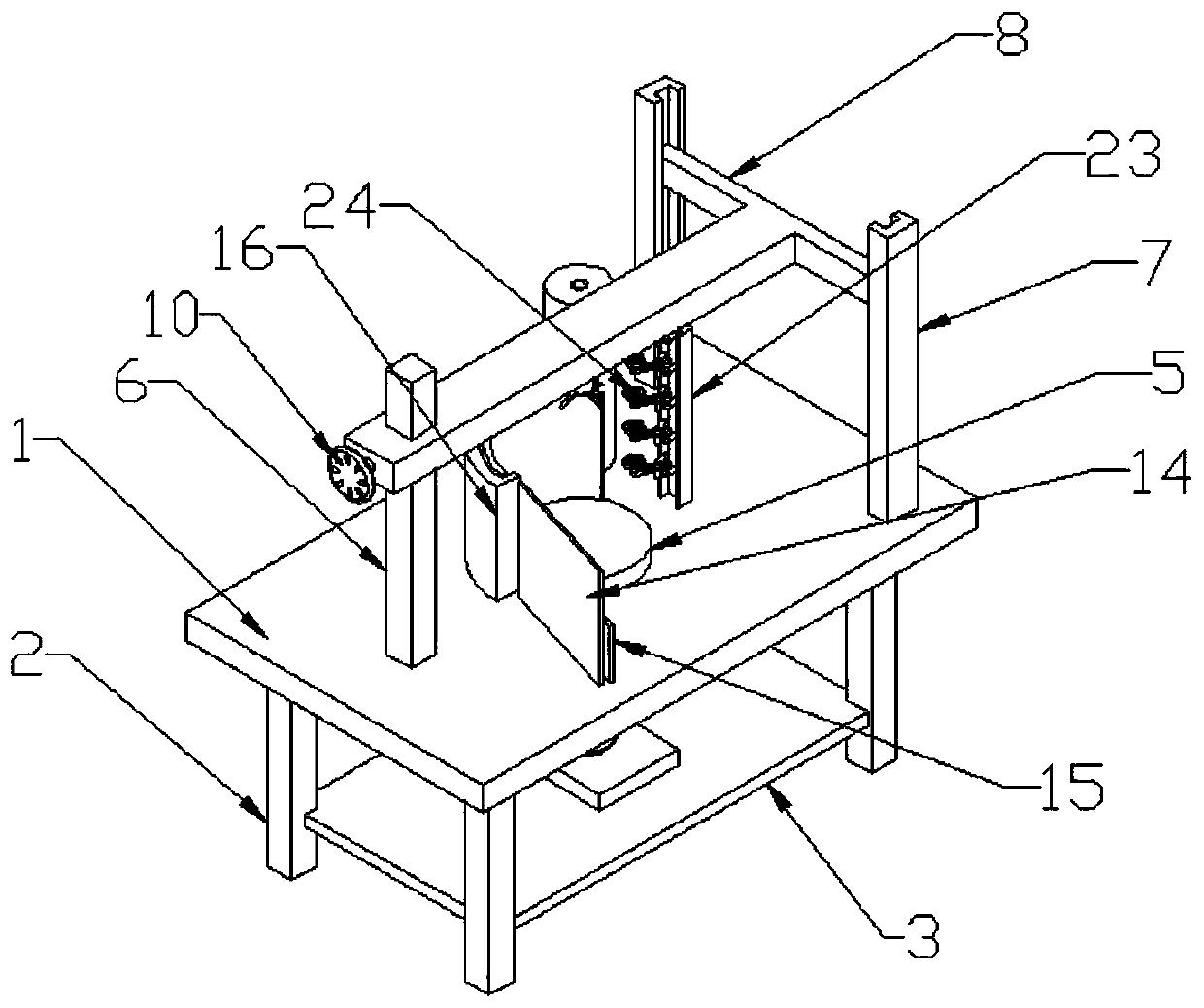

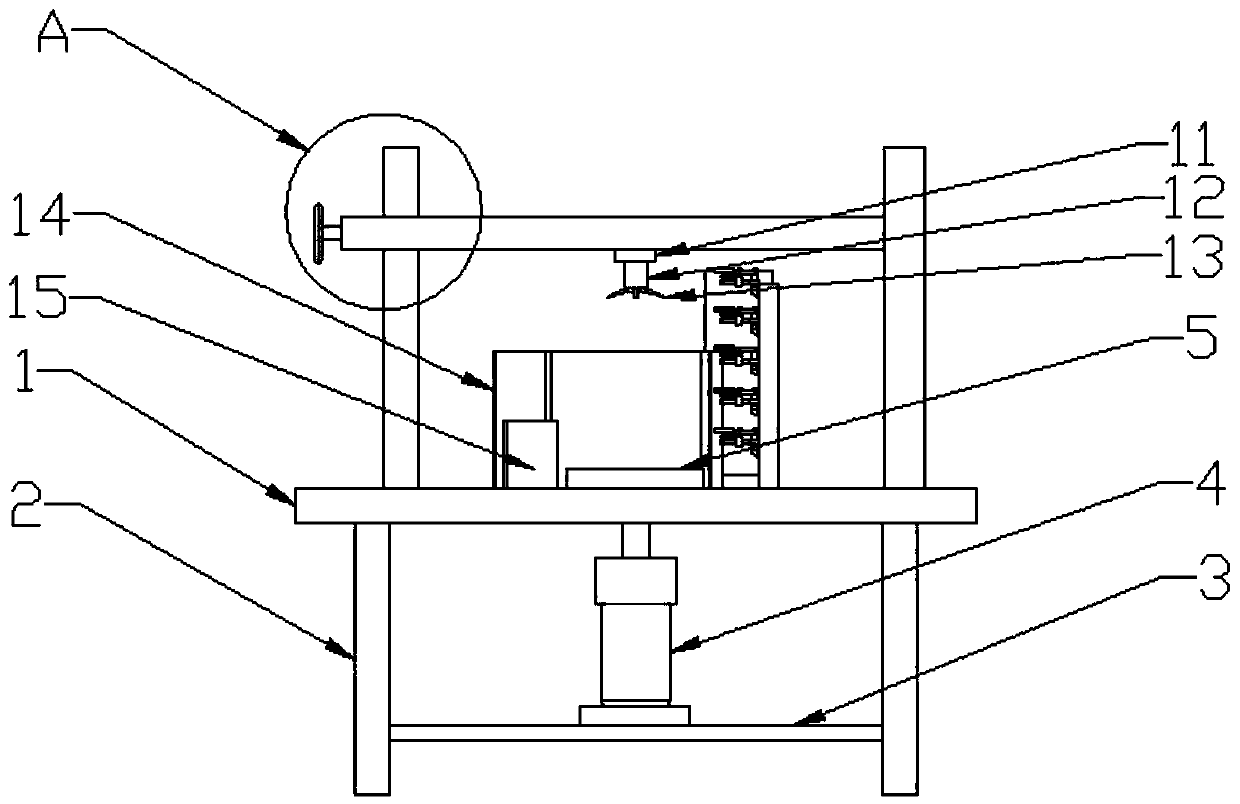

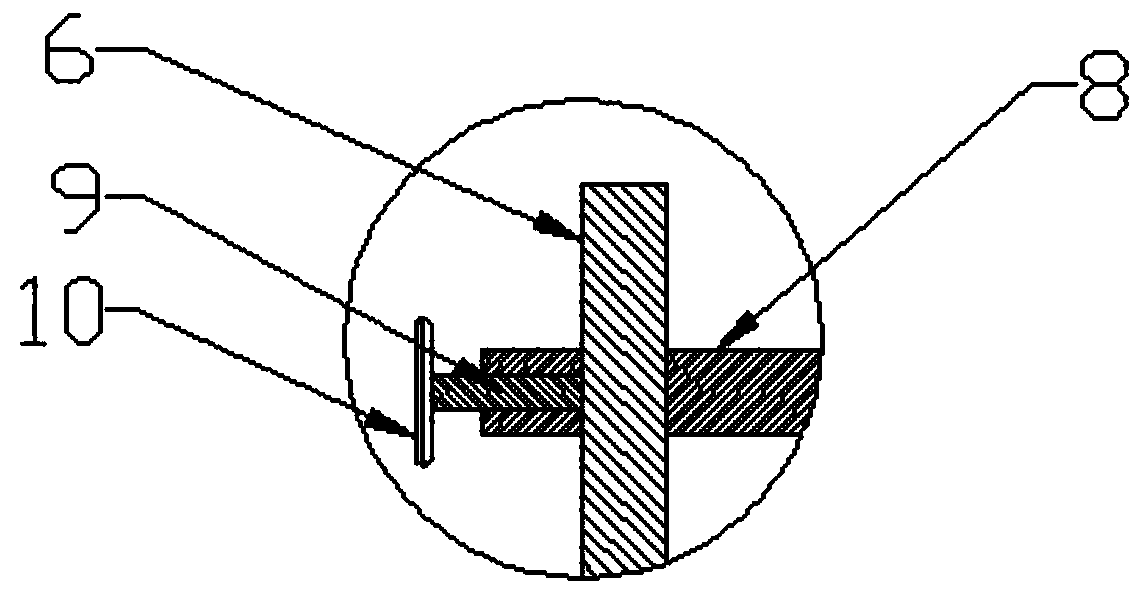

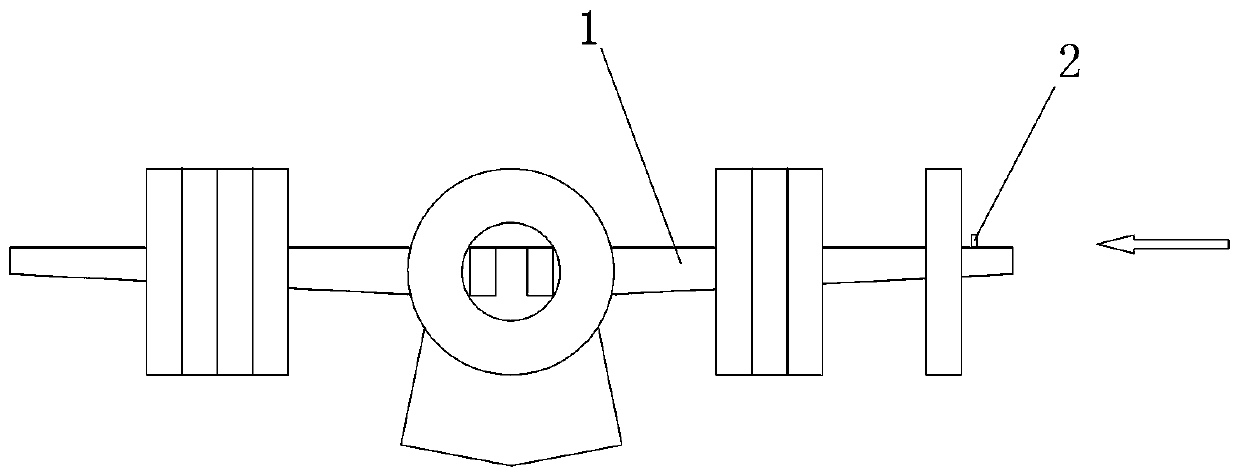

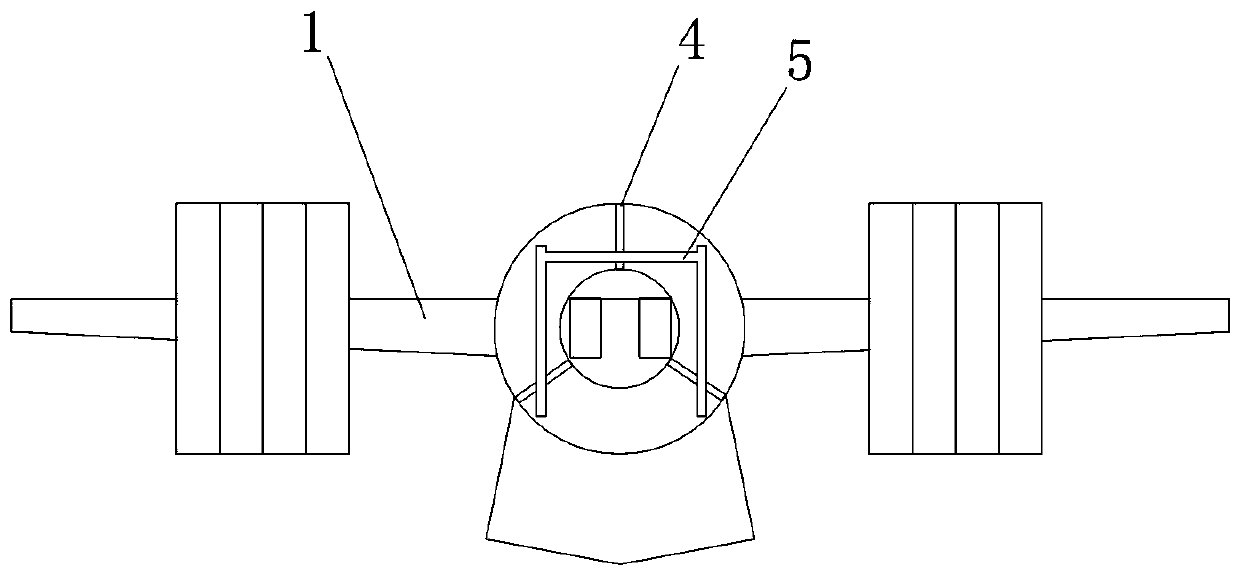

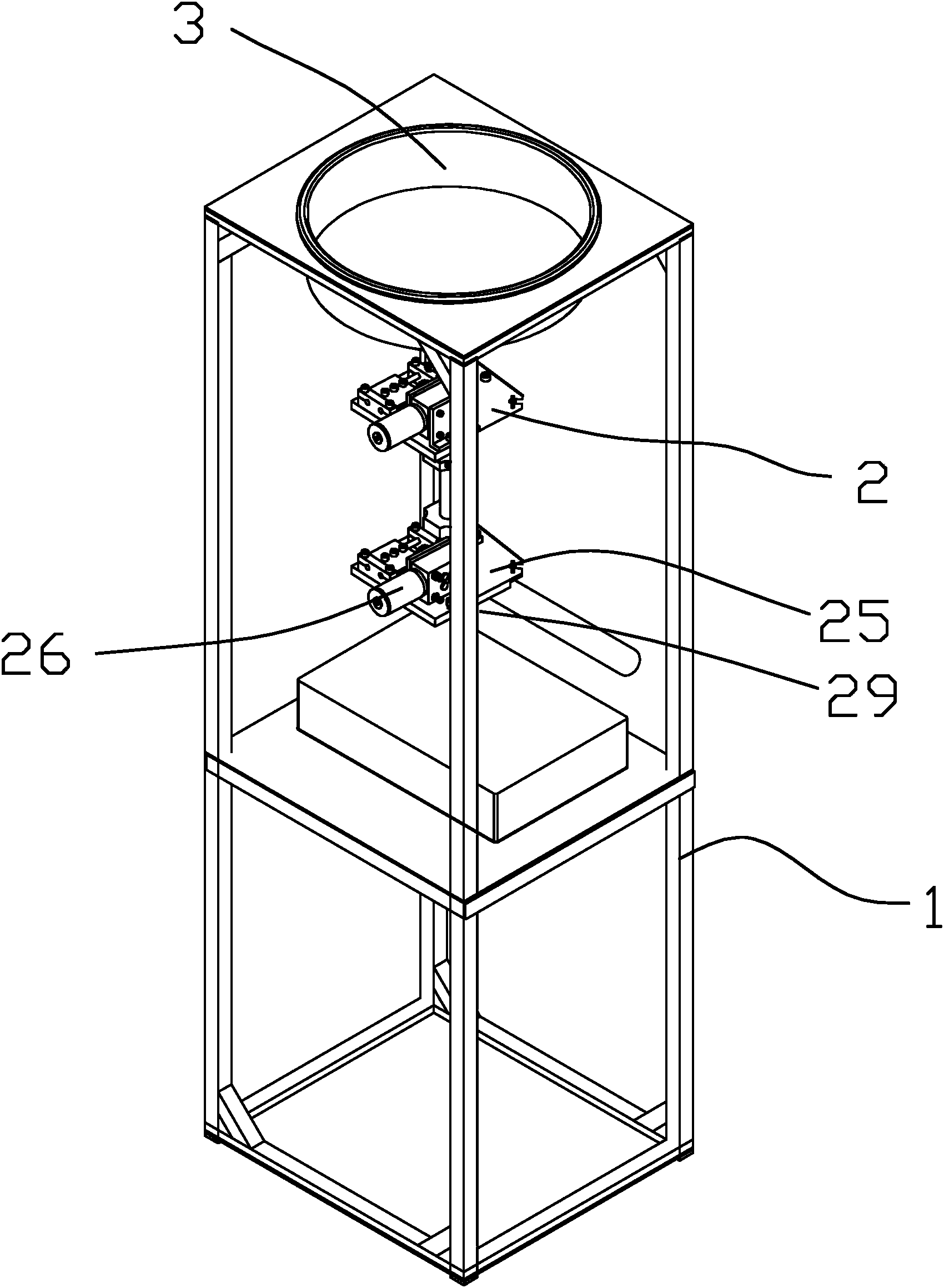

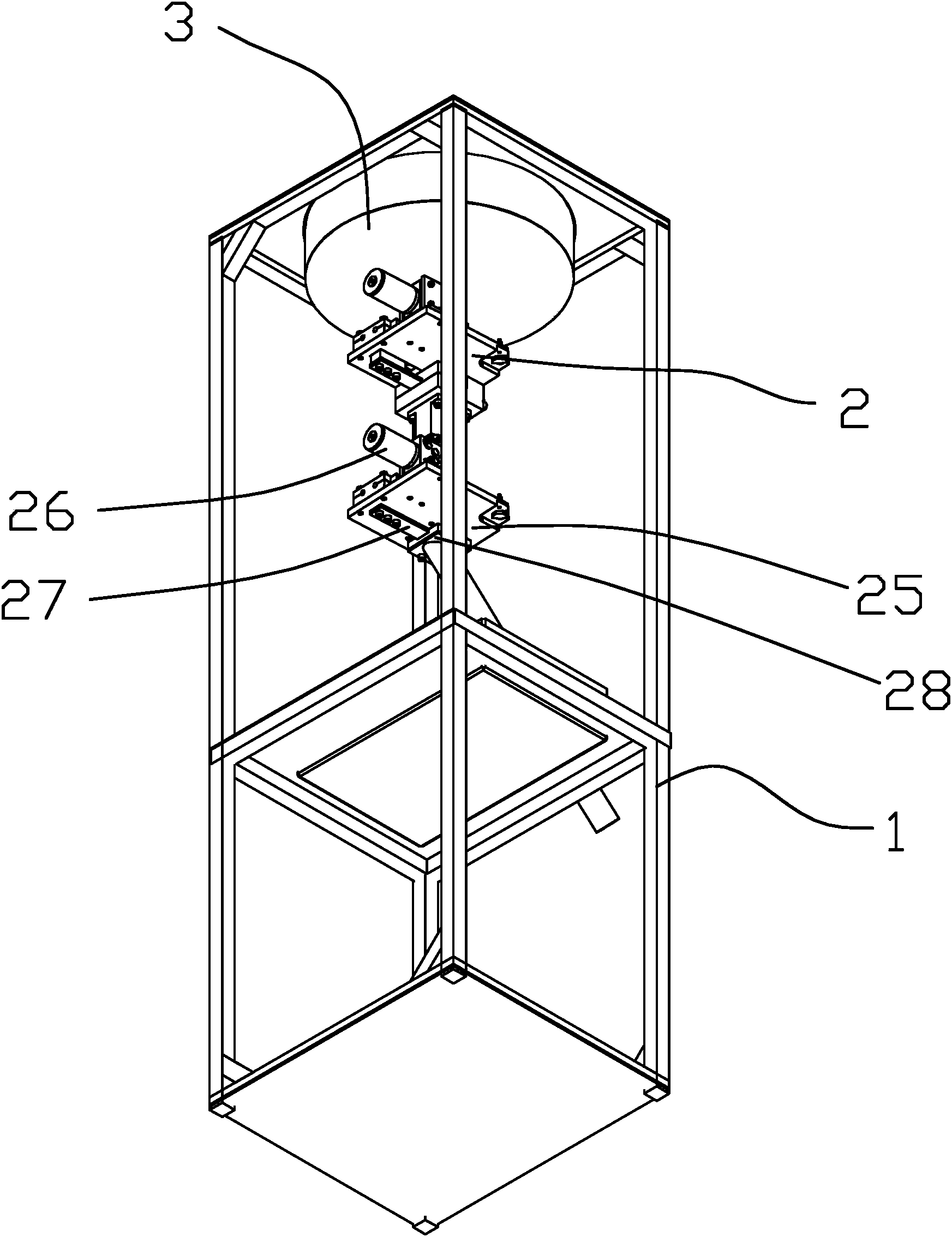

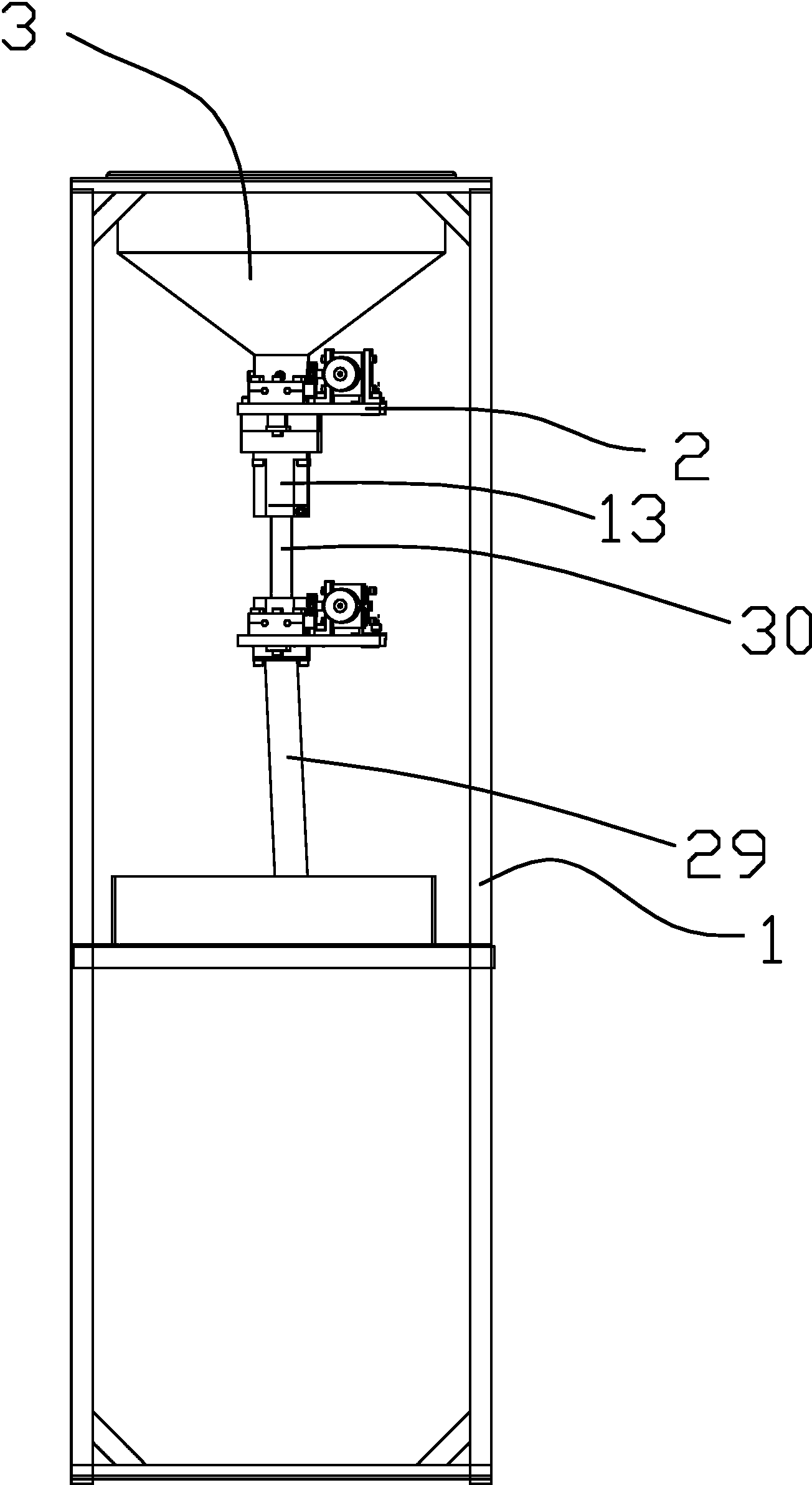

Steel ball racking machine

ActiveCN102910301ARealize automatic packagingReduce labor intensitySolid materialControl systemSteel ball

The invention discloses a steel ball racking machine comprising a rack, a funnel arranged on the rack, an upper valve sealing mechanism, a lower valve sealing mechanism, a racking cylinder, an upper chute, a discharge cylinder, a lower chute, a discharge pipe and a control system, wherein the upper valve sealing mechanism comprises a first supporting plate arranged on the rack, a first driving mechanism is arranged on the first supporting plate, a first transmission mechanism is connected to the first driving mechanism, a first propelling mechanism is connected to the first transmission mechanism, and an upper valve is connected to the first propelling mechanism; the discharge cylinder is arranged on the bottom surface of a second supporting plate, a discharge hole is arranged in the discharge cylinder, a material storage cavity is communicated with the discharge hole, and a lower valve can simultaneously seal the outlet of the material storage cavity and the inlet of the discharge hole; the lower chute is arranged on the discharge cylinder, the lower valve is located in the lower chute, and the inlet of the discharge hole is located in the bottom surface of the lower chute; the discharge pipe is connected with the discharge cylinder; and the control system is electrically connected with the first driving mechanism and a second driving mechanism.

Owner:中山市乾润精密钢球制造有限公司

Environment-friendly high-cushioning polyurethane packaging material

ActiveCN104774304BImprove buffering effectSolve environmental problemsEnvironmental resistanceOzone layer

The invention discloses an environment-friendly high-buffering-property polyurethane packaging material. The packaging material is formed by mixing a combined polyether raw material and polymethylene polyphenyl isocyanate, wherein the combined polyether raw material is composed of, by proportion, 40-45 parts of polyether trihydric alcohol, 30-40 parts of polyether glycol, 3-8 parts of chain extenders, 2-5 parts of foam stabilizers, 20-30 parts of water, 0.3-0.6 part of dimethylamino ethylether and 0.3-0.5 part of triethylene diamine. The proportion of the polymethylene polyphenyl isocyanate to the combined polyether raw material is 0.8-1.0:1. The material has a good buffering property, the buffering property is three times that of a general foaming material, and the material has good elasticity, and can be used repeatedly, and foamed and formed into the packaging material anytime and anywhere within a short time; as the water is used for replacing other foaming agents, intensity is low, the production cost is reduced, substances damaging an ozone layer are avoided, pollution is really reduced, and the environment-friendly effect of the foaming agent is completely achieved.

Owner:河南铎润新材料有限公司

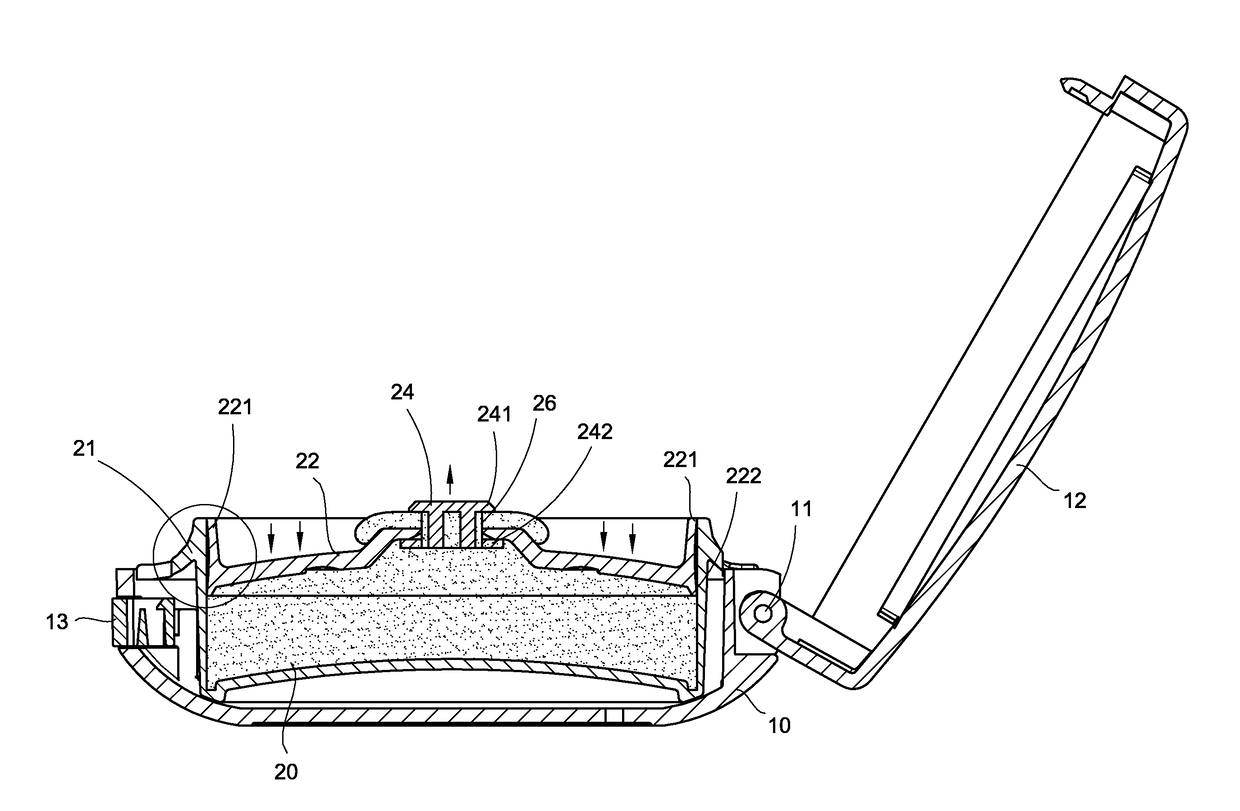

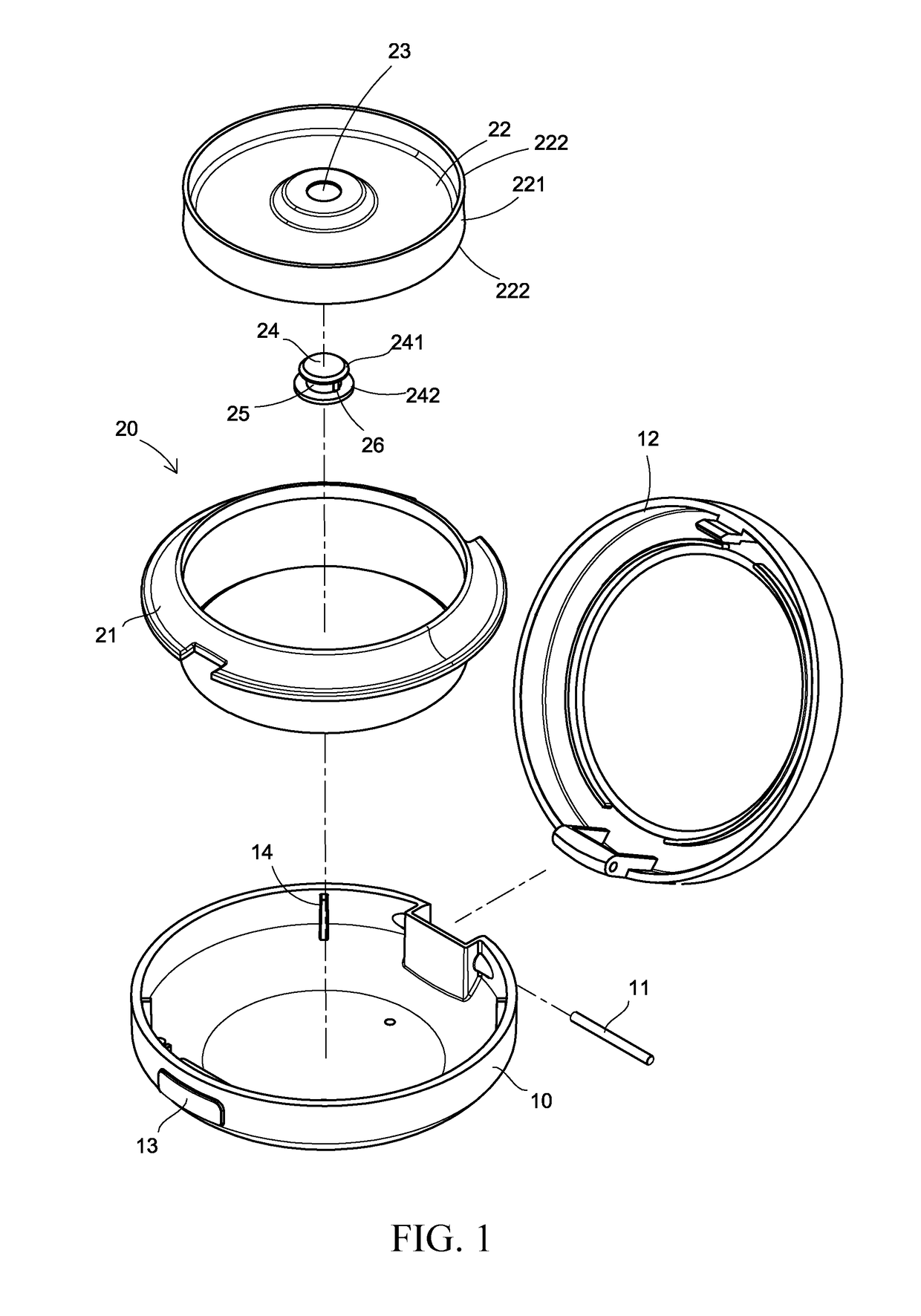

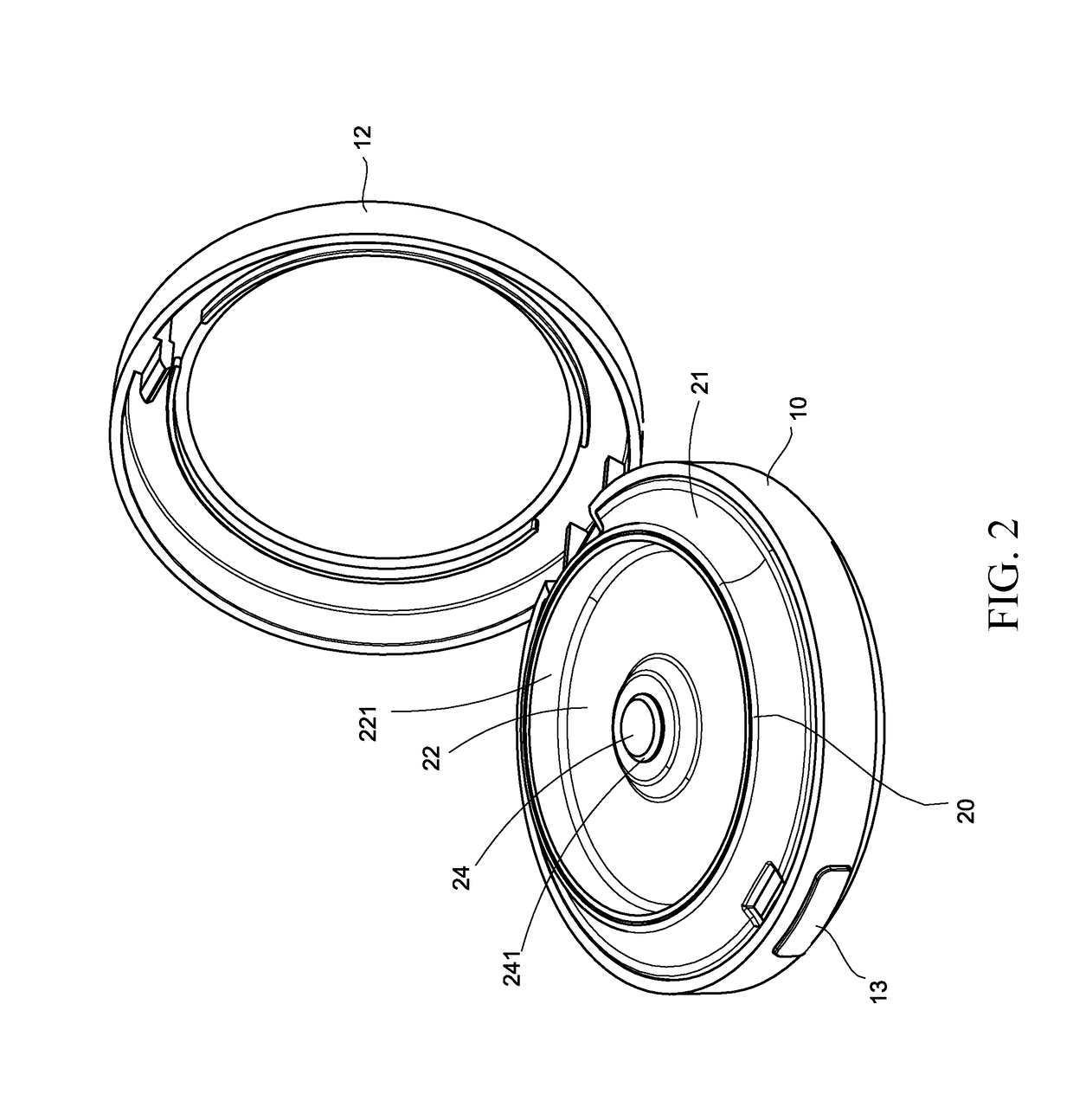

Compact type liquid fundation packing container structure

InactiveUS20180140073A1Easy to carryPackaging safetyClosuresPackaging toiletriesInternal pressureHermetic packaging

A compact type liquid foundation storing container structure provides a movable disk having the same cone design as the bottom of an inner case inserted in a main body for the insertion thereof in an opening on the top of the inner case and thereby covering it. The internal pressure in the inner case is increased when the movable disk is pressed down to push a central piston at the center of the movable upward, and liquid material stored in the inner case is guided by guide slots of the plug to flow out at the same time, thereby allowing a user to take the liquid material. After make-up, the plug is simply pressed down to close the through hole. Thereafter, the cover is covered on the main body; the internal space of the package can then be sealed in an airtight way.

Owner:CHANG CHIA SHENG

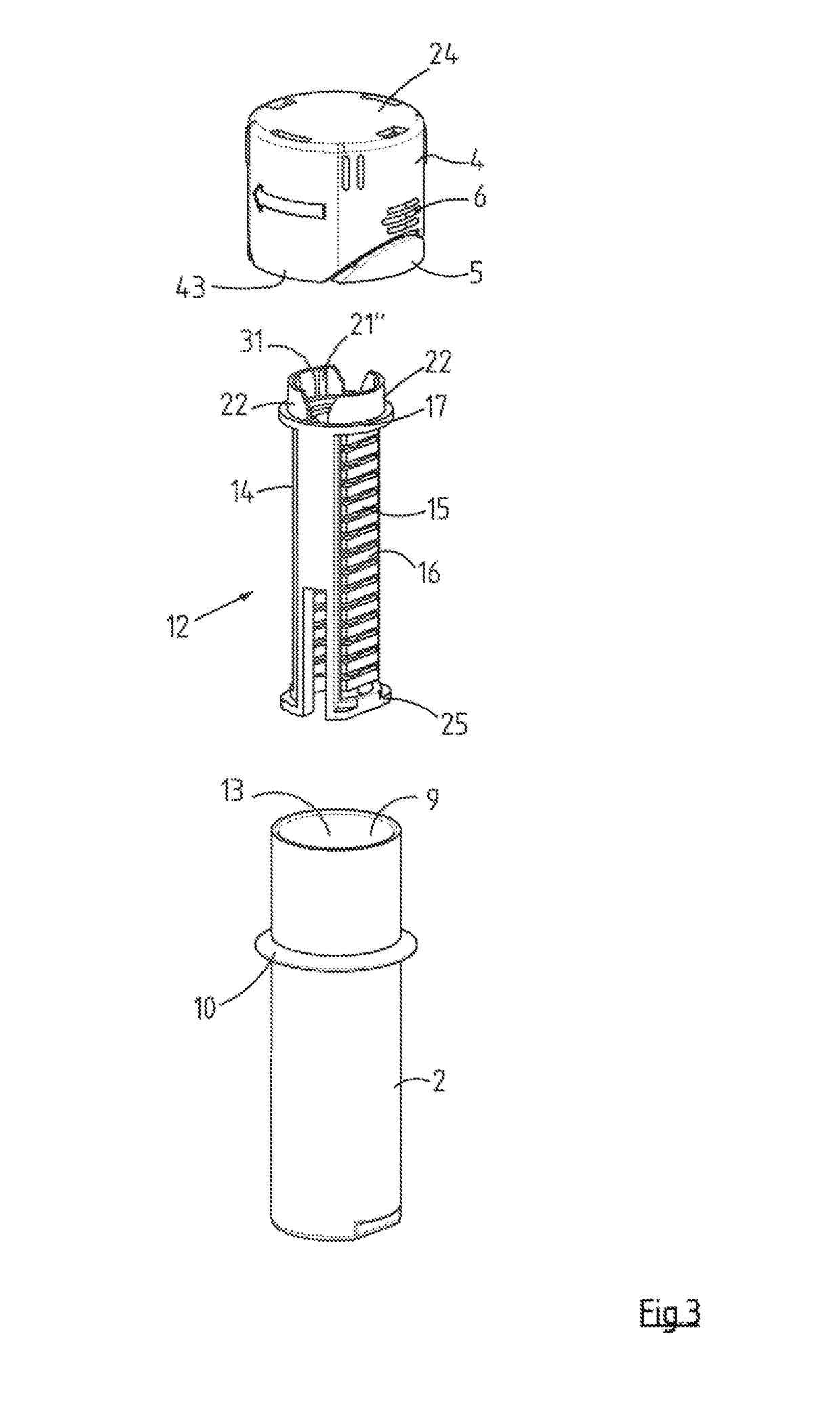

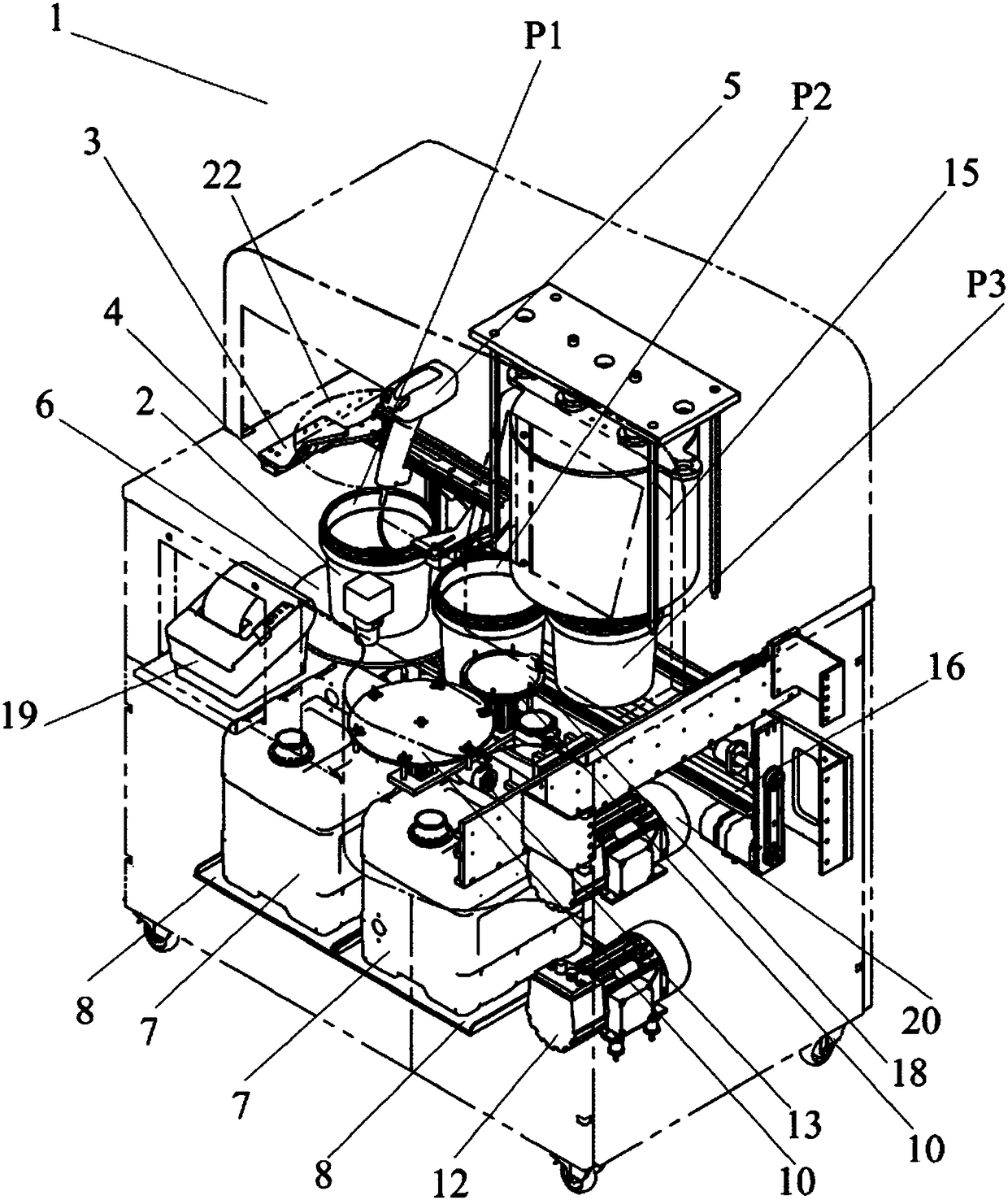

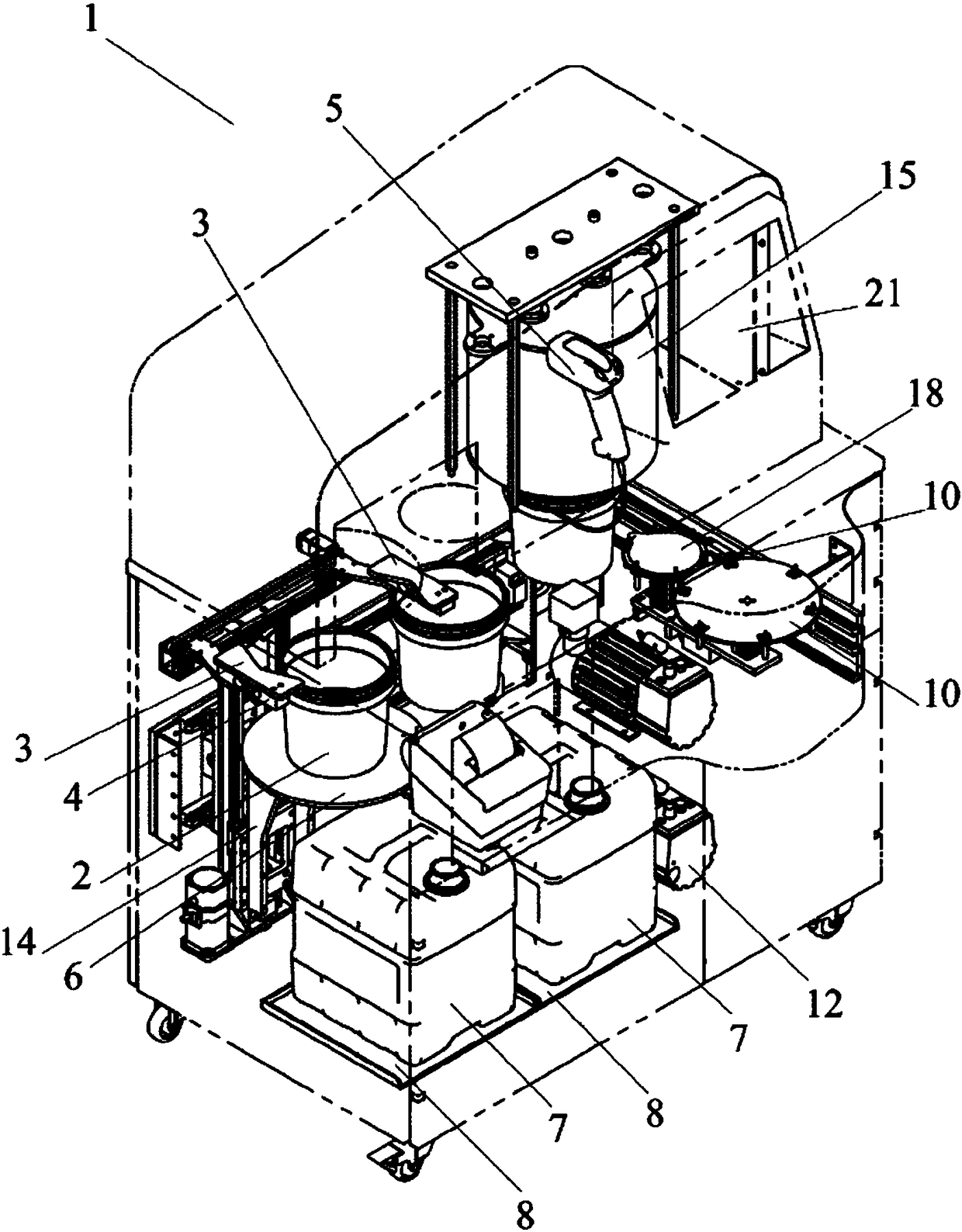

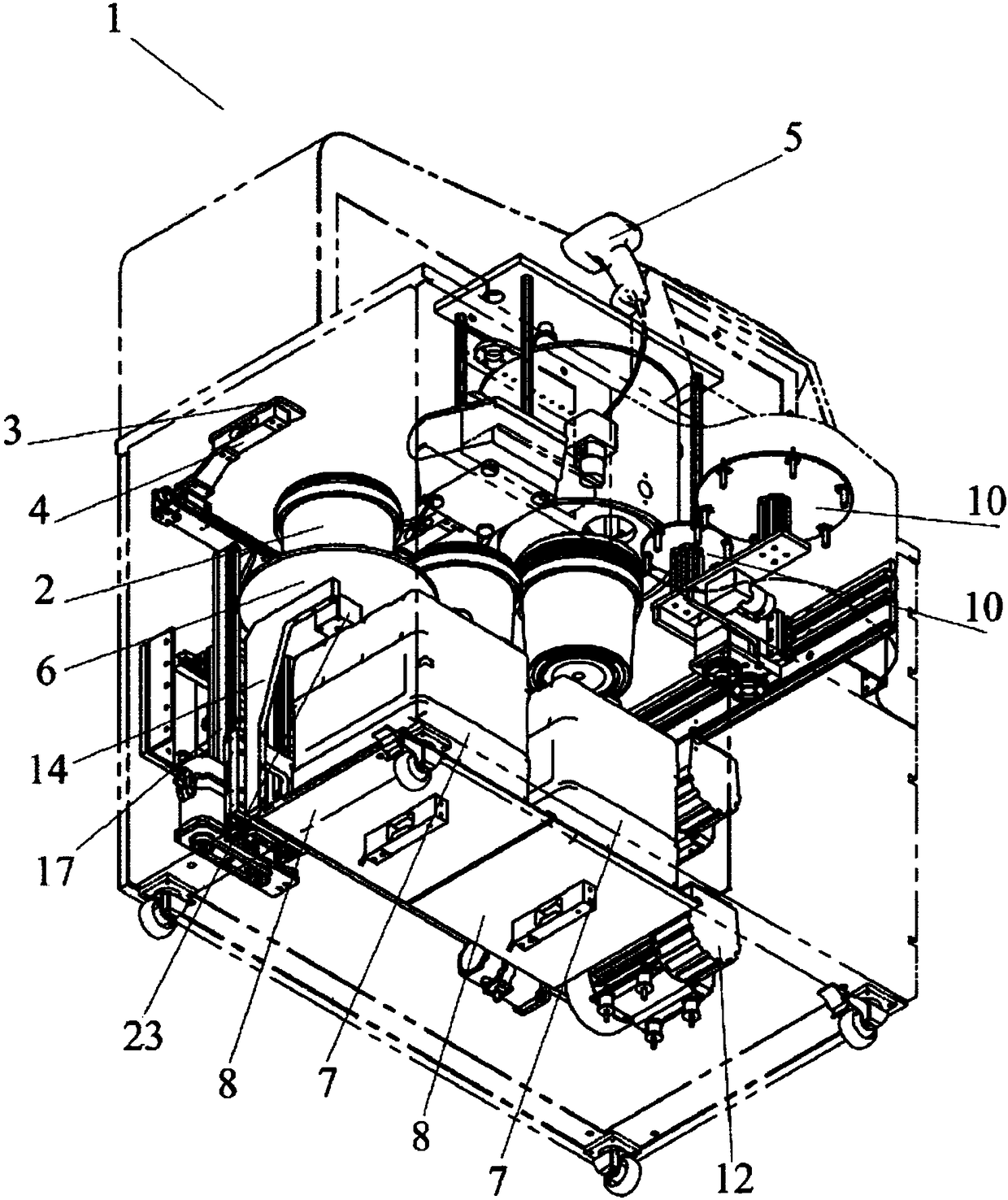

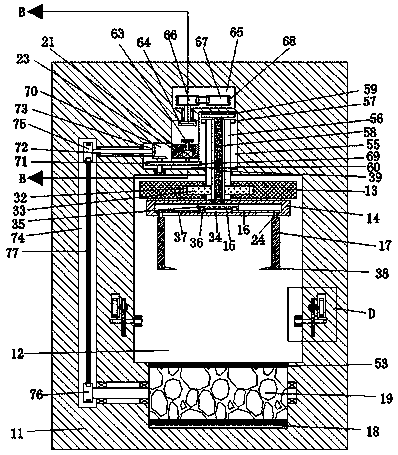

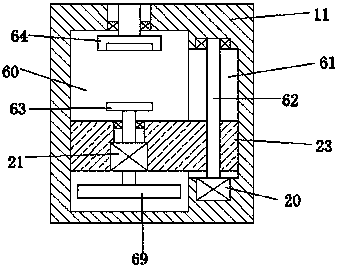

Automatic machine for the packaging, preservation and transport of surgical, histological, autopsy and cytological specimens by healthcare workers in safety

InactiveCN108602574APackaging safetyKeep safePreparing sample for investigationPackaging under vacuum/special atmospherePathological anatomyEngineering

This invention relates to the field of pathological anatomy, in particular to the sector related to the packaging and handling of histological samples and, more specifically, to a completely automaticmachine for the packaging, preservation and transport of surgical, histological, cytological and autopsy specimens by healthcare workers in safety.

Owner:MECATRON AUTOMAZIONE +1

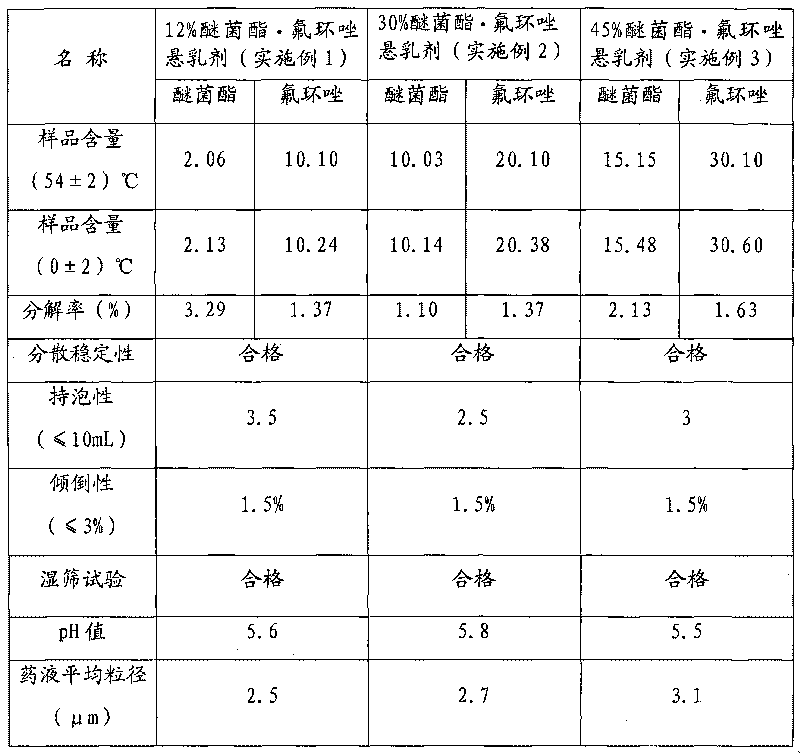

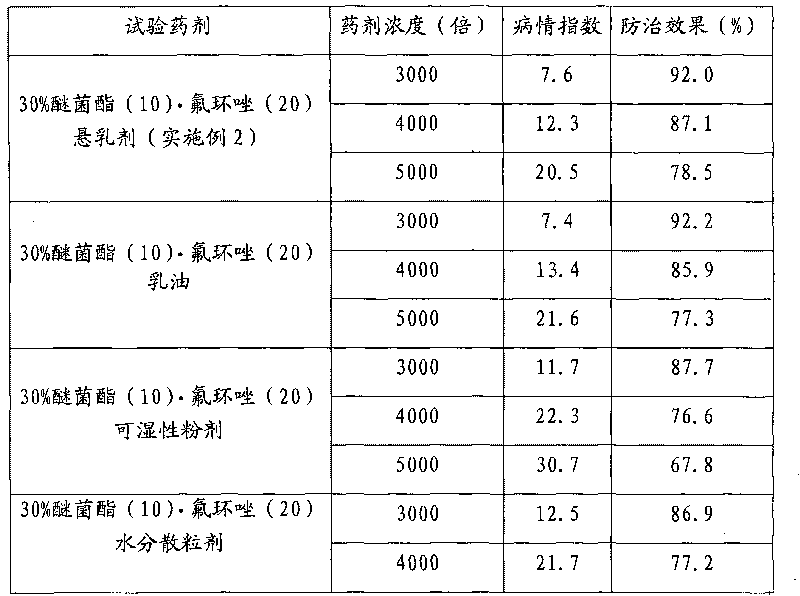

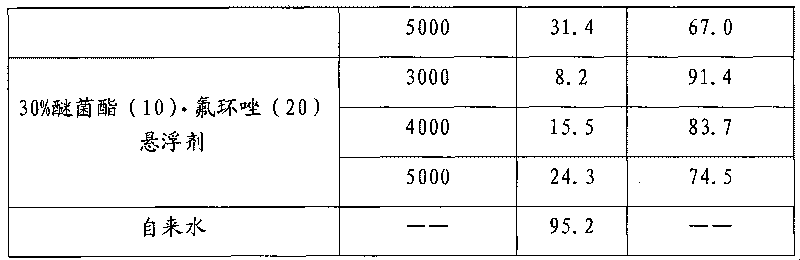

Kresoxim methyl and epoxiconazole composition suspended emulsion and preparation method thereof

The invention discloses a kresoxim methyl and epoxiconazole composition suspended emulsion and a preparation method thereof. The kresoxim methyl and epoxiconazole composition suspended emulsion comprises the following components: 2-15 percent of kresoxim methyl, 10-30 percent of epoxiconazole, 1-15 percent of solvent, 0.5-5 percent of freezing resistant agent, 1-5 percent of penetrating agent, 0.1-3 percent of thickening agent, 0.1-3 percent of defoaming agent, 5-12 percent of surface active agent and the balance of water. The invention overcomes the defects existing in the traditional formulation and enable the production, transportation and use of a product to be safer.

Owner:SHENZHEN NOPOSION AGROCHEM

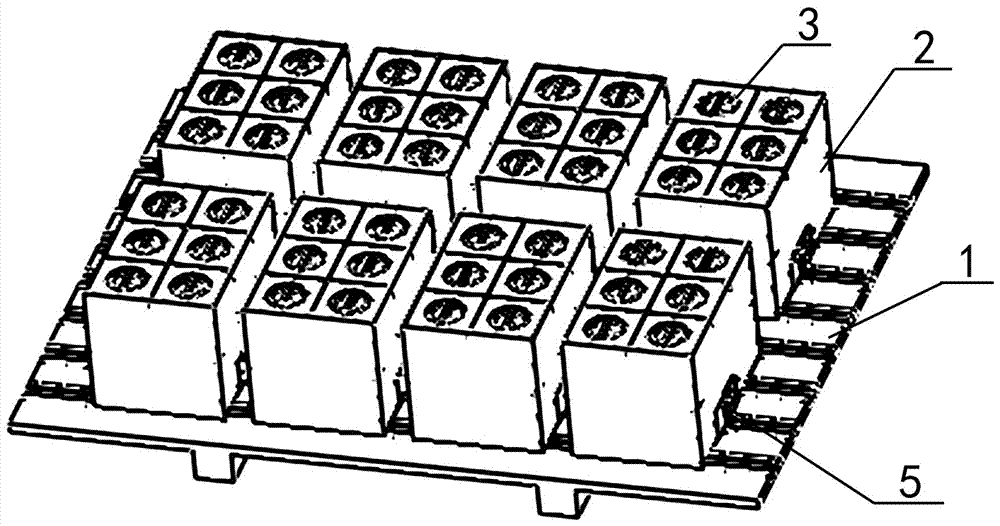

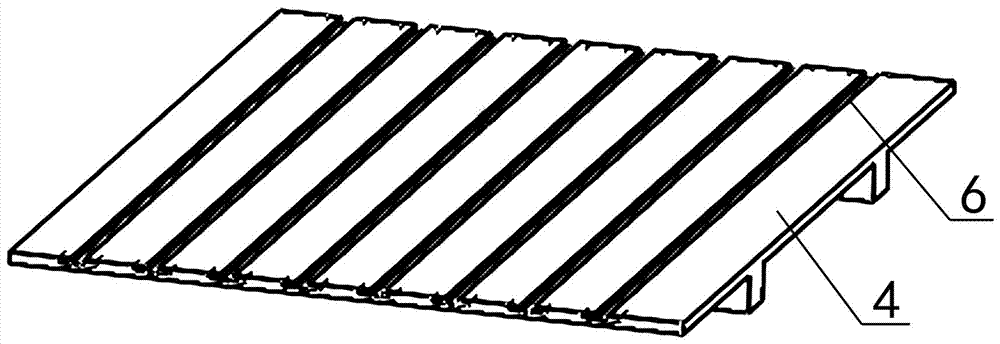

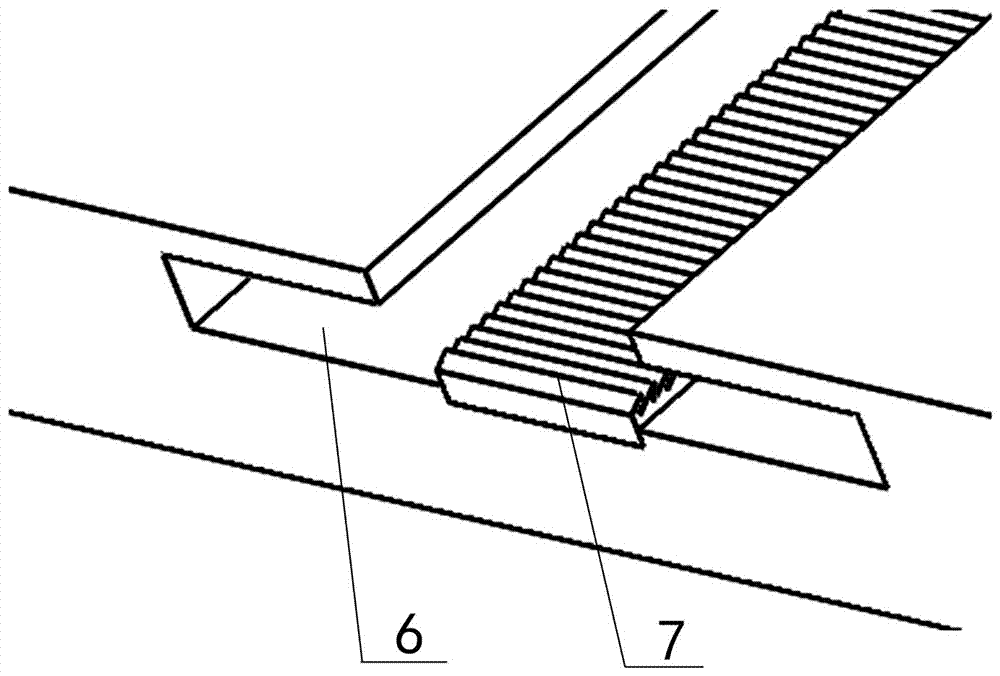

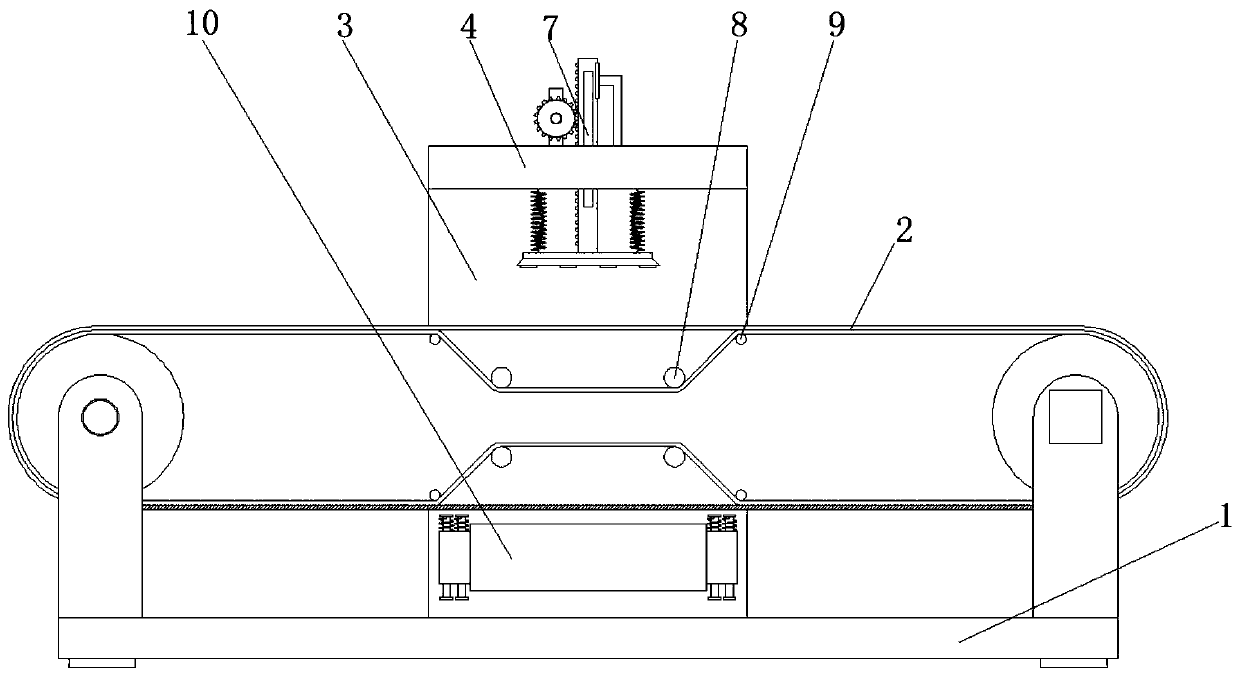

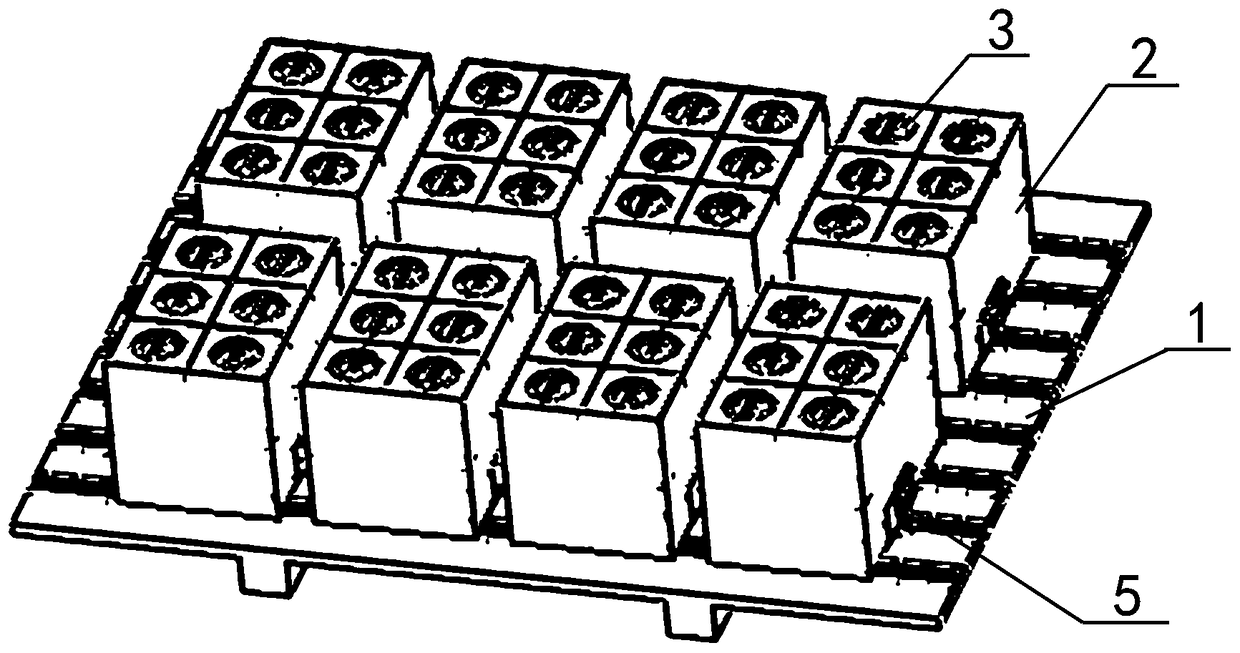

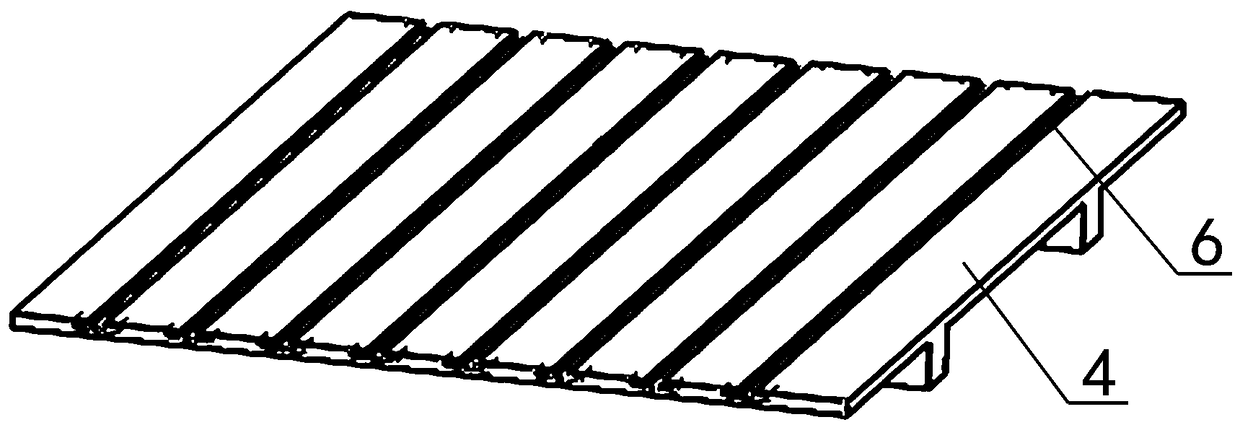

High-grade fragile product packaging and transporting integrated device

InactiveCN107226261ASuit one's needsAchieve reuseContainers to prevent mechanical damageRigid containersSelf lockingEngineering

The invention belongs to the technical field of packaging devices and provides a high-grade fragile product packaging and transporting integrated device in order to solve the technical problem that high-grade fragile products are likely to get broken in the transportation process. The high-grade fragile product packaging and transporting integrated device comprises a transport pallet, a plurality of inner packaging boxes placed on the transport pallet and a plurality of packaging boxes arranged in the inner packaging boxes. The transport pallet comprises a pallet body and a plurality of clamping devices arranged on the pallet body and used for clamping the inner packaging boxes. The pallet body is of a cuboid structure. A plurality of parallel slideways are arranged on the upper surface of the pallet body at intervals. Slide rails are arranged in the slideways and sleeved with the clamping devices. The upper surfaces of the slide rails are provided with racks. Each clamping device comprises a self-locking control plate and a clamping plate mounted on the upper portion of the self-locking control plate. The clamping devices are arranged on the slide rails through bases of the self-locking control plates in a sleeving mode and mounted on the pallet body. The packaging device can meet the requirements of different sizes of fragile products in regular shapes and irregular shapes, can be utilized repeatedly and is easy and convenient to operate and high in safety performance.

Owner:ZHONGBEI UNIV

Non-oxidiser percarbonate particles

ActiveCN101622334APackaging safetySafe handlingInorganic/elemental detergent compounding agentsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhysical chemistryNon oxidative

Non-oxidiser particles containing sodium percarbonate and at least one additive, the amount of constituents other than sodium percarbonate in the particles being such that the particles are classified as non-oxidiser according to the standard test method O.1 of the UN Manual of Tests and Criteria, sub-section 34.4.1 and that the particles have an available oxygen content of below 12 % by weight, wherein the sodium perc arbonate is coated and / or co-granulated with the additive(s). Blends comprising such particles. Process for the production of these particles and blends. Use of these particles or blends in detergent compositions and detergent compos i tions containing them.

Owner:索尔维珀萨尔兹有限公司

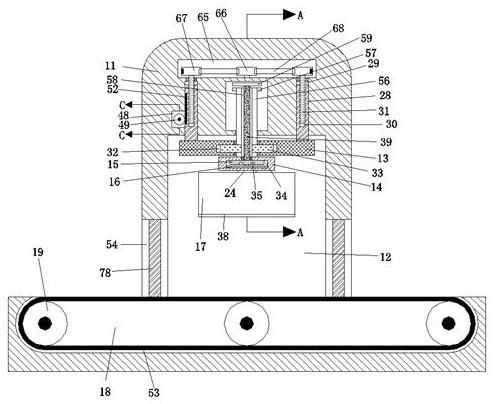

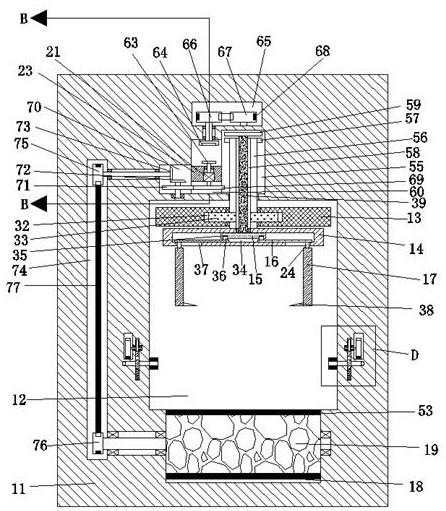

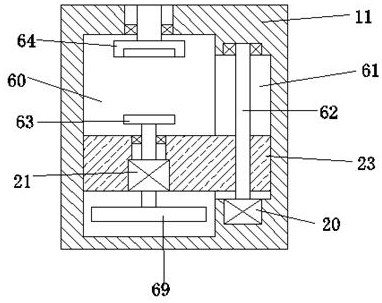

Chip packaging system

The invention discloses a chip packaging system. The chip packaging system comprises a packaging machine, wherein a packaging cavity is formed in the packaging machine; a clamping reversing device isarranged on the upper side of the packaging cavity; the clamping reversing device comprises a lifting plate arranged on the upper side in the packaging cavity; a steering wheel is rotatably arranged on the lower side of the lifting plate and is driven to lift by controlling the lifting plate and then is controlled to reverse; a control turntable is rotatably arranged in the steering wheel; slidingplates are symmetrically arranged on the lower side of the control turntable back and forth; and the sliding plates are controlled to approach and move away from each other through the control turntable. According to the chip packaging system, a plastic packaging belt can be plastically packaged through flame spraying, and meanwhile, automatic reversing can be achieved; work of the last procedures can be directly connected, the chip packaging system is quicker and labor-saving; and accidental damage caused by flame spraying can be prevented, and the chip packaging is safer and more reliable.

Owner:浙江麦知网络科技有限公司

A transportation device for food packaging with the function of removing metal multiple times

The invention relates to the technical field of food packaging, and discloses a transportation device for food packaging with the function of removing metal multiple times. There is a fixed plate, and the top of the fixed plate front is fixedly connected with a connecting plate, and the connecting plate. The present invention solves the problem that the current transportation device for food packaging is not effective in removing metal shavings and cannot be removed multiple times, so that there are still some metal shavings mixed in the food, which is inconvenient to detect and use. In the present invention, the food enters from the first conveyor belt on the upper right, the food moves to the left, and the iron filings also move to the left at the same time, and move to the center. Since there is a distance between the first conveyor belt and the second conveyor belt, the iron filings No longer being attracted, and adsorbing with the first iron filings adsorption mechanism, it is not easy to make metal filings mixed in the food.

Owner:诸城正新食品有限公司

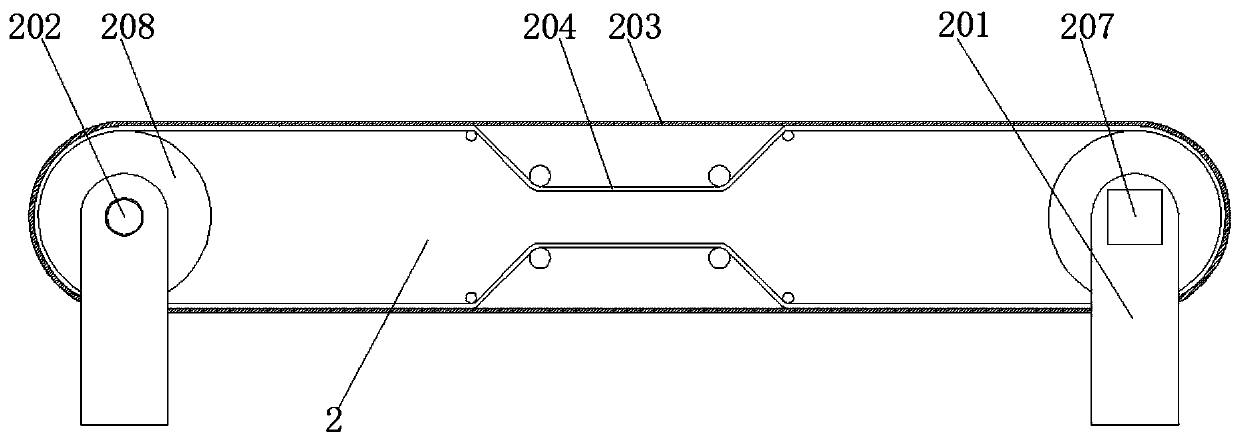

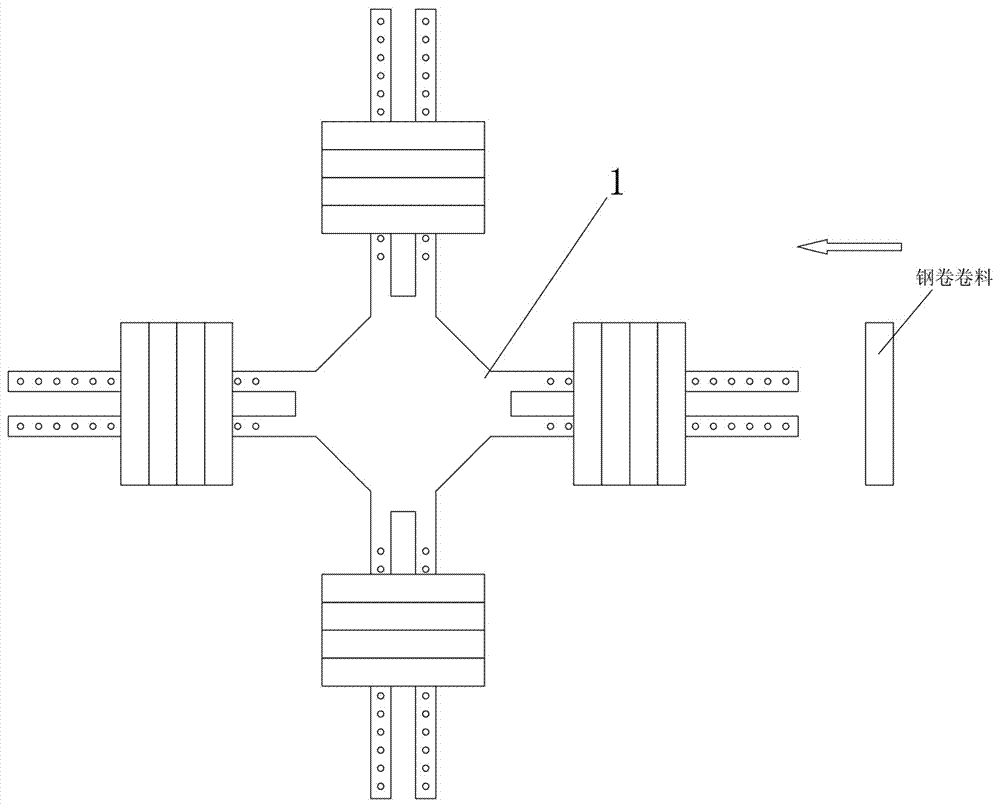

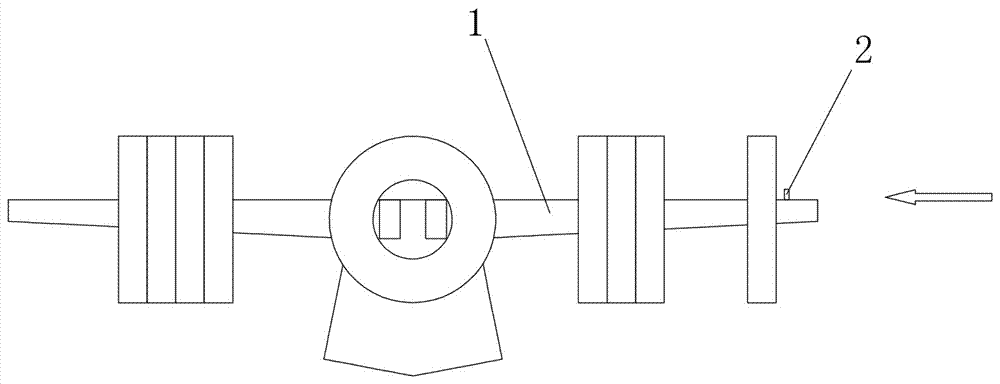

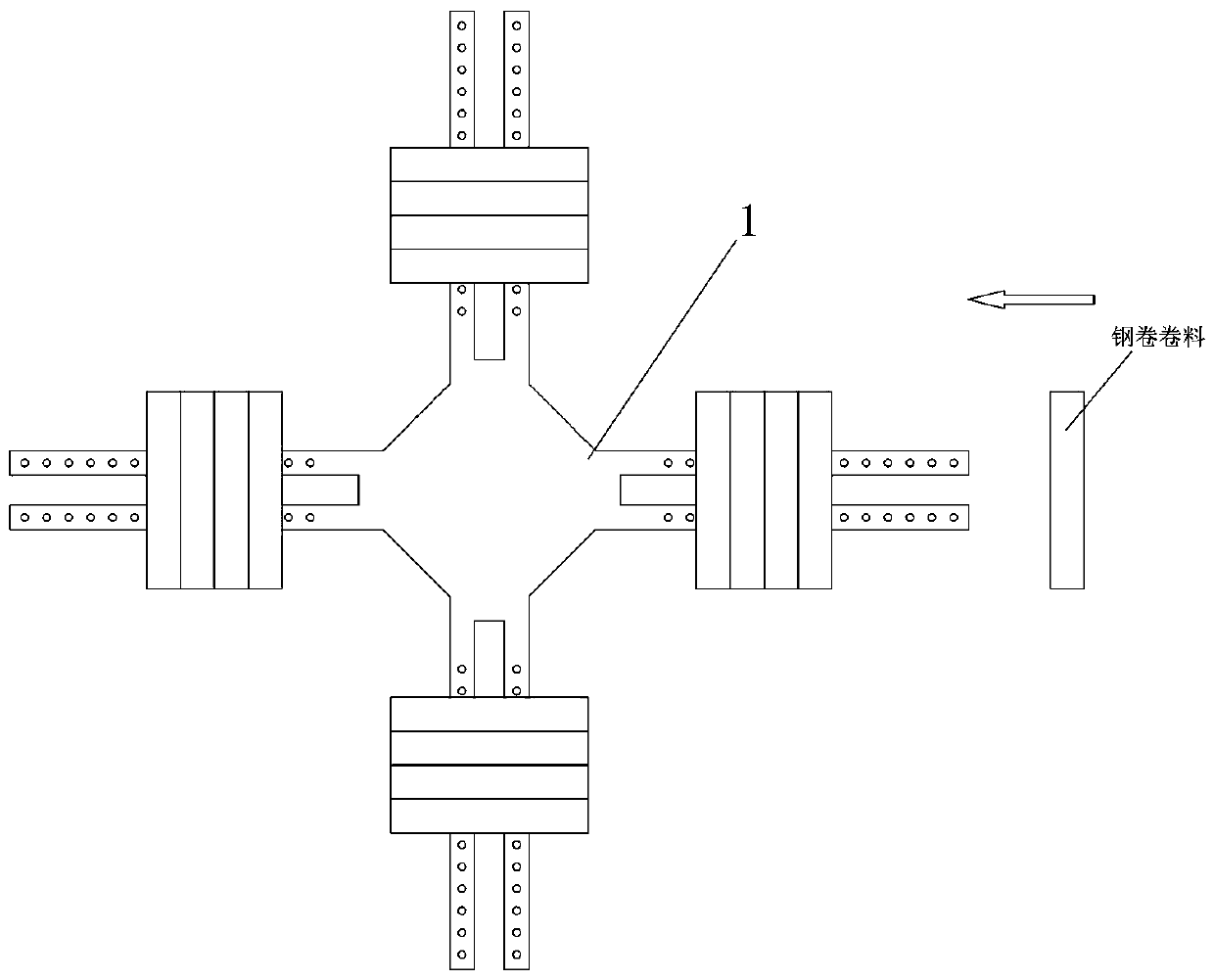

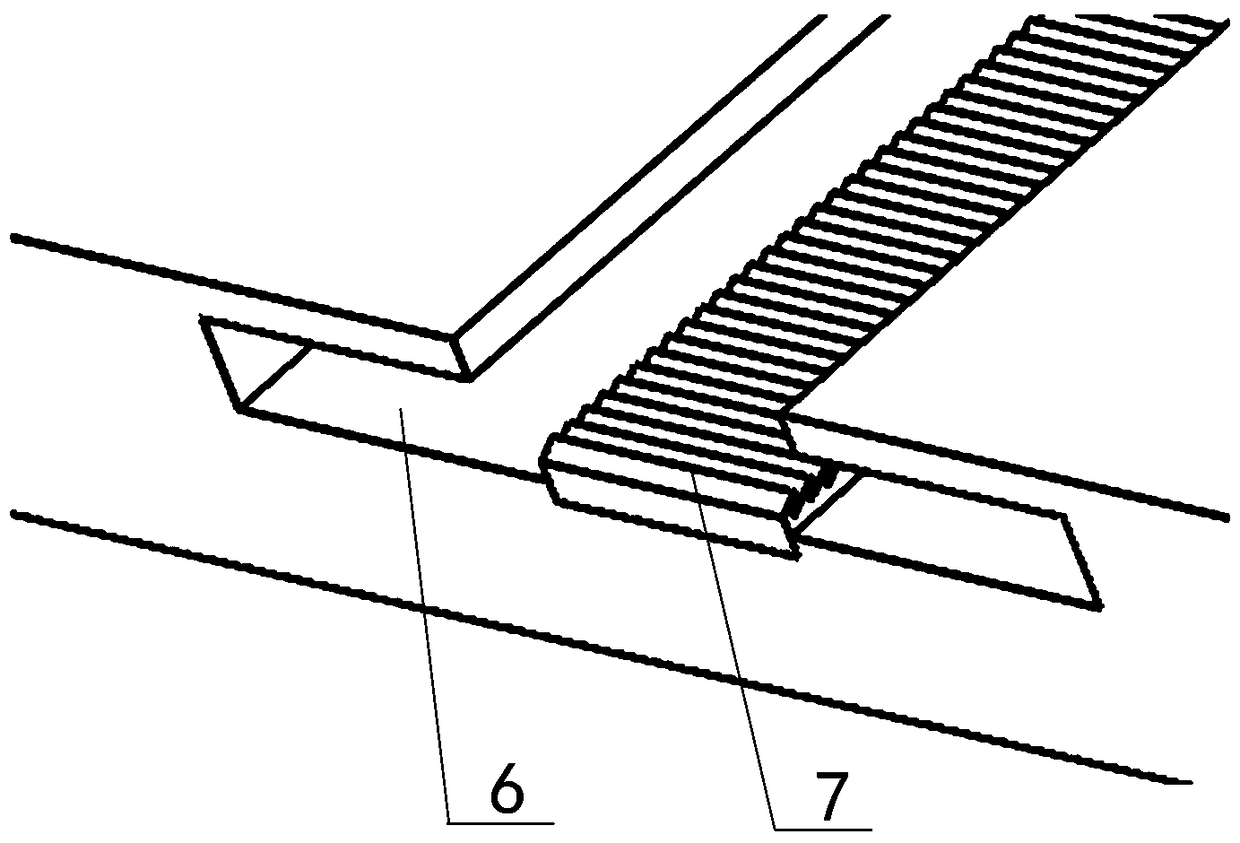

Packing method suitable for steel coil materials with width of 30-70 mm

InactiveCN107972908AEasy to usePackaging safetyBinding material applicationBundling machine detailsClockwiseMaterials science

The invention discloses a packing method suitable for steel coil materials with the width of 30-70 mm. The packing method comprises the following steps that the to-be-packed steel coil materials are unloaded from a coiling machine to a material frame cross arm; two blocking rods are inserted in a screw hole in the tail end of the material frame cross arm before packing; during packing, packing isconducted one by one from the material frame cross arm from outside to inside, a coiling separating device is used to be inserted in the position between the adjacent steel coil materials so as to separate the adjacent steel coil materials; binding bands are used, and the three binding bands are evenly distributed in the radial direction in a binding mode; the remaining coil materials are bound with the binding bands in the radial direction according to the method order, and the packed adjacent steel coil materials are separated by using a wooden frame; the single stack of bound steel coil materials is hung and transported by using a travelling crane to an overturning machine where a material frame is placed well to be overturned, then two binding bands are used to be bound together with the material frame, and labels are pasted to outer rings of the steel coil materials; and the steel coil materials are placed on the material frame, people should pay attention to the facts that burrsface downwards, and band heads are in the clockwise direction. According to the packing method suitable for the steel coil materials with the width of 30-70 mm, using is convenient, and packing is safe and reliable.

Owner:福州宝井钢材有限公司

A chip packaging system

Owner:浙江麦知网络科技有限公司

Alloy antistatic material for wafer trays, and preparation method thereof

ActiveCN109251507AIncreased permanent antistatic propertiesImprove mechanical propertiesThermoplasticAntioxidant

The invention relates to the technical field of thermoplastic engineering plastics, particularly to an alloy antistatic material for wafer trays, and a preparation method thereof, wherein the alloy antistatic material comprises, by weight, 30-50 parts of polyphenylene ether, 10-40 parts of high-impact-resistant polystyrene, 8-12 parts of electric-conduction carbon black, 3-6 parts of a styrene butadiene styrene block copolymer, 0.3-0.5 part of a silane coupling agent, 1-3 parts of a styrene-maleic anhydride copolymer, 8-12 parts of electric-conduction carbon black, 0.4-1 part of a lubricant, 3-4 parts of triphenyl phosphate, and 0.3-0.6 part of an antioxidant. According to the present invention, the alloy antistatic material has good mechanical property, and additionally achieves the permanent antistatic property of the PPO / HIPS alloy, such that the alloy antistatic material is safe in the packaging, testing and transportation of wafers.

Owner:东莞市国亨塑胶科技有限公司

Efficient and safe automatic durian packaging machine

ActiveCN110481851AImprove packaging efficiencyPackaging safetyWrapping with article rotationPackaging fruits/vegetablesPaperboardIndustrial engineering

The invention provides an efficient and safe automatic durian packaging machine, and belongs to the technical field of agricultural and sideline product packaging. Due to the fact that a durian shellis hard and is inconvenient to package and the durian shell is provided with spikes, the problem that people are prone to being damaged is solved. The packaging machine comprises a working table, a speed reducing motor, a guide machine, four supporting legs are arranged on the lower surface of the working table, a transverse pulling plate is fixedly arranged between the supporting legs, the uppersurface of the transverse pulling plate is provided with the speed reducing motor, a lifting mechanism is arranged on the upper surface of the working table, a third stand column is arranged on the upper surface of the working table, a film roll is placed on the third stand column, a fourth stand column is arranged on the surface of the working table, and a pressing mechanism is arranged on the surface of the fourth stand column. According to the efficient and safe automatic durian packaging machine, the durian is driven to rotate by the speed reducing motor, so that manual output is reduced,and the packaging efficiency of the durian is improved; and the durian is packaged through a paperboard, so that the durian can be protected well, a hard spiked shell on the surface of the durian canbe effectively prevented from stabbing workers, and the durian packaging is safer and more reliable.

Owner:山东卓辰科技服务有限公司

A packaging method suitable for steel coils with a width of 30-70mm

InactiveCN107972908BEasy to usePackaging safetyBinding material applicationBundling machine detailsEngineeringClockwise

Owner:福州宝井钢材有限公司

Pancreatic color doppler transforming agent and preparation method thereof

InactiveCN109620975AReduce misdiagnosisShort detection timeEchographic/ultrasound-imaging preparationsSolution deliveryTapioca starchPancreatic structure

The invention discloses a pancreatic color doppler transforming agent and a preparation method thereof. The pancreatic color doppler transforming agent consists of the following raw materials, by weight, 10%-17% of wheat flour, 28%-32% of rice, 2%-6% of wild rice shoot, 2%-6% of citrus peel, 2%-7% of tapioca, 17%-25% of soybean, 5%-12% of Chinese yam, 5%-12% of mung bean and 1%-5% of stevioside, and the total content of the above raw materials is 100%. The pancreatic color doppler transforming agent can well stay in the stomach to be matched with the color doppler for ultrasonic penetration, so that an imaging interface similar to the liver tissues can be formed after the stomach and the duodenum, pancreatic organs can be observed clearly to reduce misdiagnosis caused by unclear imaging ofthe pancreas due to the interference of the stomach and the duodenum, and the agent has the advantages of short detection time, high imaging efficiency and stable effect.

Owner:贾皓然

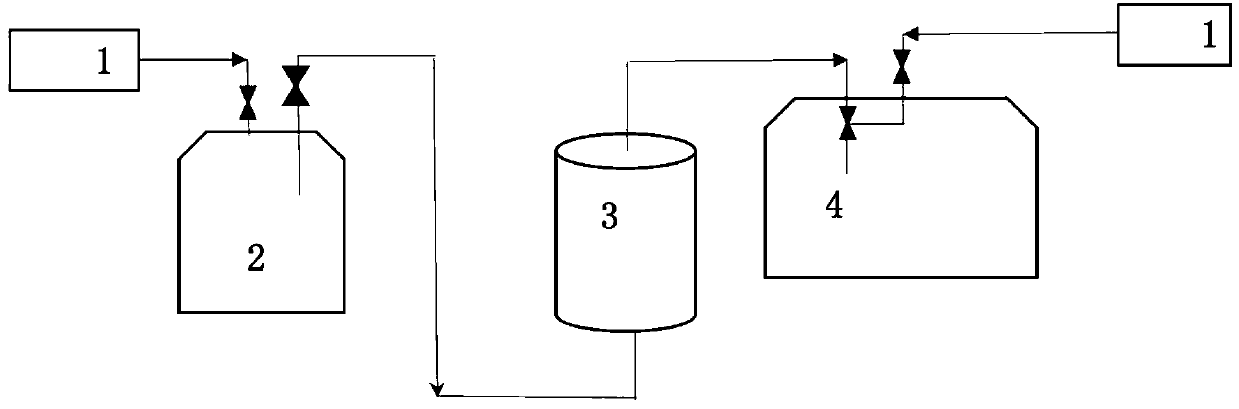

Method for split packaging of n-butyllithium solution

InactiveCN109835856APackaging safetyAvoid product qualityThreaded caps applicationFilling using counterpressureN-ButyllithiumGas phase

The invention relates to a method for split packaging of the packing specification of 1 L or below of a n-butyllithium solution. The method is used for split packaging of the n-butyllithium solution in small packages, the split packaging process is carried out in an all-inert gas environment and is safe and controllable, and split-packaged products are clear and free of impurities. The method comprises the following two steps that 1, split packaging is carried out on the n-butyllithium solution, specifically, 1-1, inert gas is introduced in a suppressed mode from a gas phase (gas phase valve)of a 100 L steel cylinder containing the n-butyllithium solution, liquid flows out through the liquid phase valve, is filtered and then is connected to a glove box, split packaging is carried out in the glove box filled with the inert gas, the n-butyllithium solution is transferred into reagent bottles by virtue of pipeline transfer, and 1-2, after split packaging is completed, the reagent bottlescan be safely taken out from the glove box; and 2, n-butyllithium in a pipeline is treated, specifically, after split packaging is completed, the gas phase valve of the steel cylinder is opened for pressure relief, a split packaging valve which makes contact with the reagent bottles in the glove box are closed, argon is introduced from the right side, and the residual n-butyllithium solution in the pipeline is blown into the steel cylinder.

Owner:盘锦研峰科技有限公司

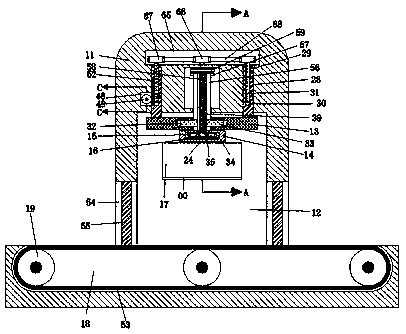

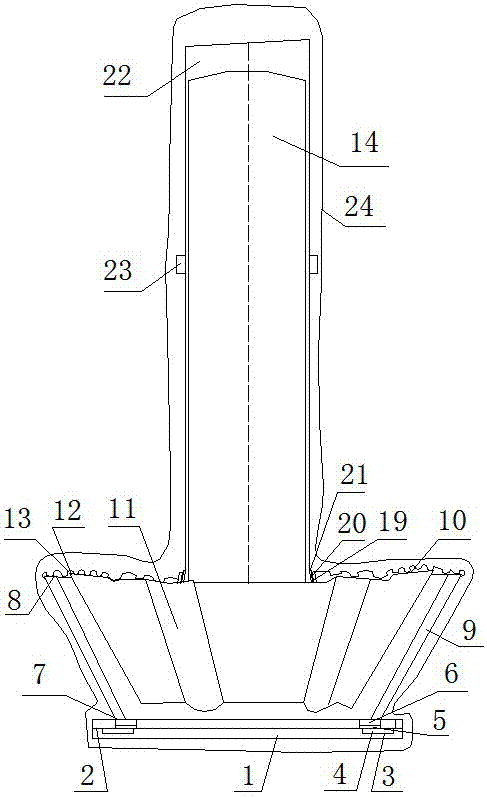

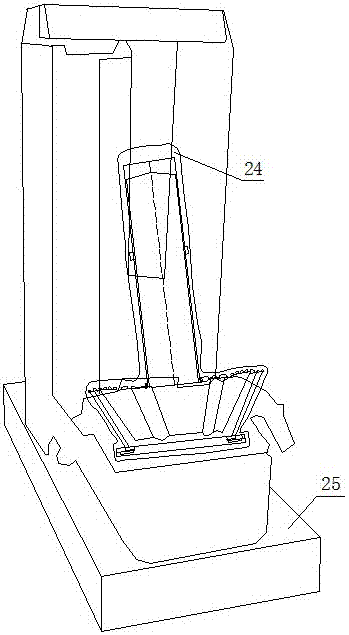

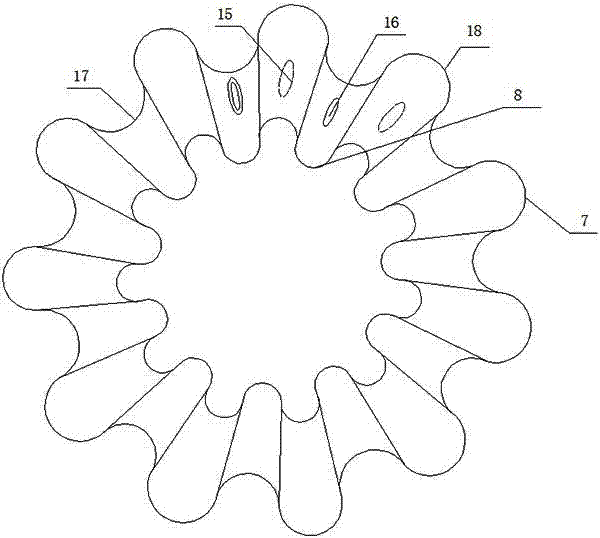

Vacuum locking device for umbrella-shaped drill bit

PendingCN107954081AImprove protectionPackaging safetyClosuresPackaging under vacuum/special atmosphereEngineeringDrill bit

The invention discloses a vacuum locking device for an umbrella-shaped drill bit. The vacuum locking device consists of a bottom plate, wherein a circular ring slot is formed in a position, around theperiphery, of the bottom plate; the cross section of the circular ring slot is L-shaped; a group of circular hole slots is formed in positions, around the periphery, of the flat bottom surface of thecircular ring slot; the circular hole slots are adhered with magnetic sheets which attract magnetic rings; the magnetic rings are adhered on the bottoms of circular ring bottom plates; the circular ring bottom plates are fixedly connected with an umbrella-shaped fixed cover; the bottom of the umbrella-shaped fixed cover is in the shape of a lower circle; the top of the umbrella-shaped fixed coveris in the shape of an upper circle; the diameter of the upper circle is greater than that of the lower circle; the wall of the umbrella-shaped fixed cover is provided with wrinkles; the top of the umbrella-shaped fixed cover is covered with an open wrinkled circular ring; the umbrella-shaped drill bit is arranged in the umbrella-shaped fixed cover; the pointed end on the top of the umbrella-shaped drill bit is inserted into a raised edge of the open wrinkled circular ring; and the umbrella-shaped drill bit is fixedly connected with a drill rod. The vacuum locking device is used for vacuum locking of the umbrella-shaped drill bit.

Owner:TIANJIN TIANMEN JINBAO TECH CO LTD

High-grade fragile goods packaging and transportation integrated device

InactiveCN107226261BMeet actual needsAchieve reuseContainers to prevent mechanical damageRigid containersEngineeringSelf locking

The invention belongs to the technical field of packaging devices and provides a high-grade fragile product packaging and transporting integrated device in order to solve the technical problem that high-grade fragile products are likely to get broken in the transportation process. The high-grade fragile product packaging and transporting integrated device comprises a transport pallet, a plurality of inner packaging boxes placed on the transport pallet and a plurality of packaging boxes arranged in the inner packaging boxes. The transport pallet comprises a pallet body and a plurality of clamping devices arranged on the pallet body and used for clamping the inner packaging boxes. The pallet body is of a cuboid structure. A plurality of parallel slideways are arranged on the upper surface of the pallet body at intervals. Slide rails are arranged in the slideways and sleeved with the clamping devices. The upper surfaces of the slide rails are provided with racks. Each clamping device comprises a self-locking control plate and a clamping plate mounted on the upper portion of the self-locking control plate. The clamping devices are arranged on the slide rails through bases of the self-locking control plates in a sleeving mode and mounted on the pallet body. The packaging device can meet the requirements of different sizes of fragile products in regular shapes and irregular shapes, can be utilized repeatedly and is easy and convenient to operate and high in safety performance.

Owner:ZHONGBEI UNIV

Pancreas color doppler converting agent and preparation method thereof

InactiveCN109675066AReduce misdiagnosisShort detection timeEchographic/ultrasound-imaging preparationsColor dopplerLiver tissue

The invention discloses a pancreas color doppler converting agent and a preparation method thereof. The pancreas color doppler converting agent is prepared from the following raw materials in percentage by weight: 10 to 17 percent of wheat powder, 28 to 32 percent of rice, 1 to 5 percent of zizania aquatica, 2 to 6 percent of madarin orange peel, 8 to 12 percent of tapioca flour, 26 to 32 percentof soybean, 3 to 7 percent of brown rice and 1 to 5 percent of stevioside. The total percentage of the raw materials is 100 percent. The pancreas color doppler converting agent provided by the invention can be well remained in the stomach to match a color doppler for ultrasonic penetration, so that a liver tissue type imaging interface is realized after the passing through the stomach and duodenum; therefore the pancreas organ can be clearly observed; the misdiagnosis due to unclear pancreas imaging due to the interference by the stomach and duodenum can be reduced. The pancreas color dopplerconverting agent has the characteristics of short detection time, high image development efficiency and stable effects.

Owner:贾皓然

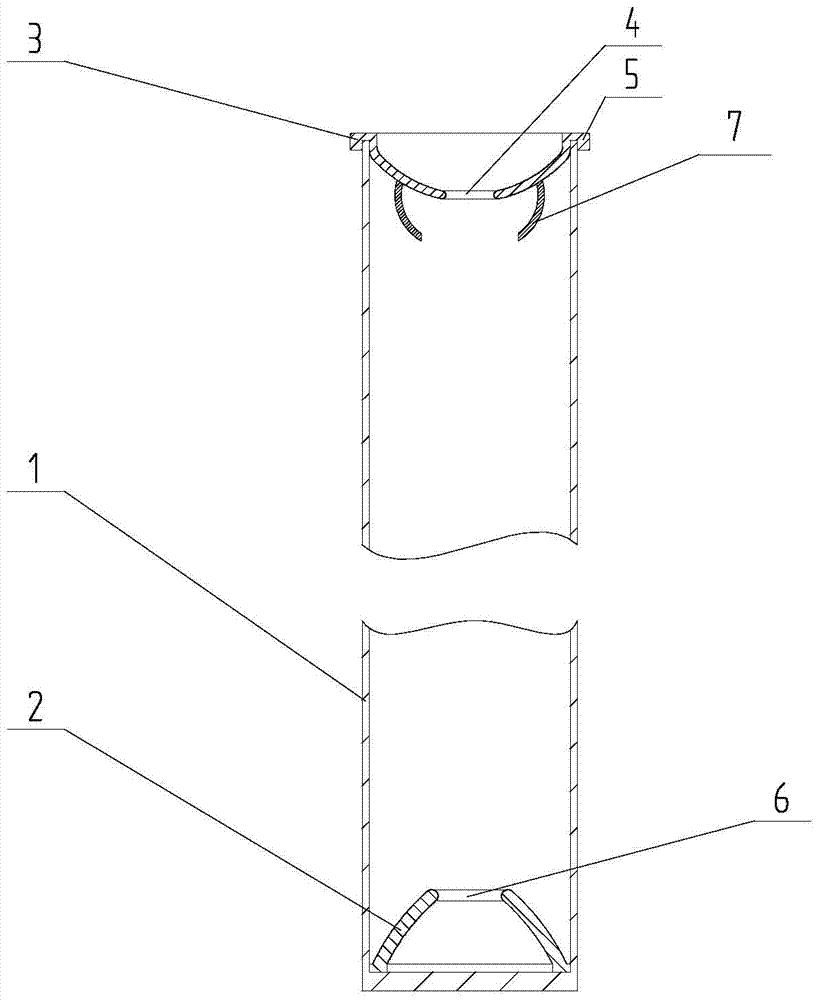

Cylindrical packaging device for modulator tube

InactiveCN104709609ASimple structureImprove buffering effectDamagable goods packagingInternal fittingsEngineeringPackaging Case

Owner:WUXI ZHONGHUAN PACKAGING

Alloy antistatic material for wafer tray and preparation method thereof

ActiveCN109251507BIncreased permanent antistatic propertiesImprove mechanical propertiesThermoplasticPolymer science

The invention relates to the technical field of thermoplastic engineering plastics, particularly to an alloy antistatic material for wafer trays, and a preparation method thereof, wherein the alloy antistatic material comprises, by weight, 30-50 parts of polyphenylene ether, 10-40 parts of high-impact-resistant polystyrene, 8-12 parts of electric-conduction carbon black, 3-6 parts of a styrene butadiene styrene block copolymer, 0.3-0.5 part of a silane coupling agent, 1-3 parts of a styrene-maleic anhydride copolymer, 8-12 parts of electric-conduction carbon black, 0.4-1 part of a lubricant, 3-4 parts of triphenyl phosphate, and 0.3-0.6 part of an antioxidant. According to the present invention, the alloy antistatic material has good mechanical property, and additionally achieves the permanent antistatic property of the PPO / HIPS alloy, such that the alloy antistatic material is safe in the packaging, testing and transportation of wafers.

Owner:东莞市国亨塑胶科技有限公司

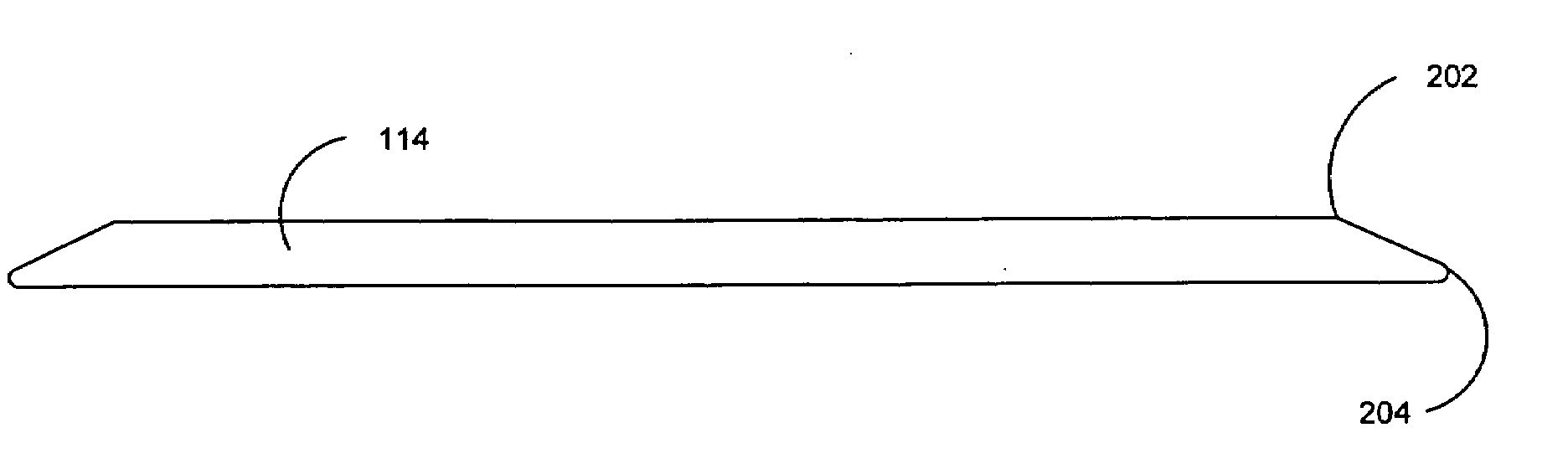

Tempered Glass Chair Mat and Method of Packaging

ActiveUS20090155531A1Increase mobilityEasily disposeWrappers shrinkageTreadsCommon carrierEngineering

A glass chair mat and method of packaging comprising a sheet of tempered glass with rounded corners and rounded beveled edges. The tempered glass chair mat may be finished to enhance its appearance or left translucent to showcase the flooring underneath. The method of packaging allows a minimal amount of employees to safely package the glass chair mat for delivery to residence and businesses alike. Furthermore, the packaging provides additional protection against damage during transit and assures common carriers are aware of the fragile nature of the package.

Owner:KBJ ENTERPRISES

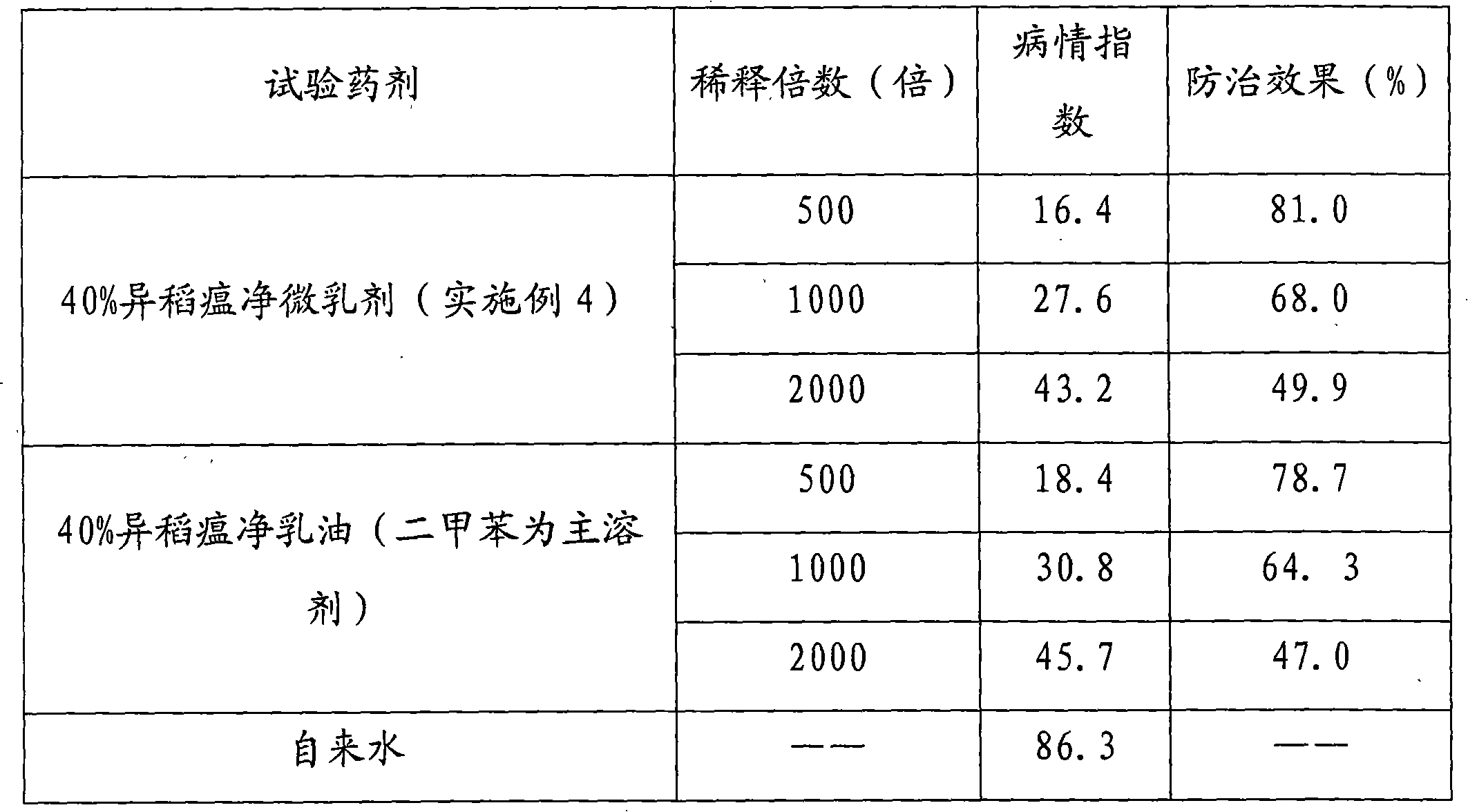

Iprobenfos microemulsion and manufacturing method thereof

InactiveCN101647467AAvoid pollutionLow toxicityBiocideFungicidesOrganic solventSurface-active agents

The invention discloses an iprobenfos microemulsion and a manufacturing method thereof. The iprobenfos microemulsion is prepared from 5-40 percent of iprobenfos, 0-5 percent of cosolvent, 0.5-5 percent of stabilizer, 8-20 percent of surface active agent and water up to 100%. In the iprobenfos microemulsion, aromatic organic solvent in missible oil is replaced by water, thereby preventing the environment from being polluted by triphenyl organic solvent and ensuring safer production, package, transportation and use, and simple and easy production technique. The iprobenfos microemulsion has thinner liquor particles than the missible oil after being diluted, which is favorable for the absorption of crops, thereby improving the use ratio of medicaments and enhancing the prevention and treatmenteffect of medicaments.

Owner:SHENZHEN NOPOSION AGROCHEM

Rosemary extract preparation process

InactiveCN112322296ASolving physical and chemical properties is not good enoughSolve the problem of poor solubilization effectOrganic chemistryEssential-oils/perfumesProcess engineeringOrganic chemistry

The invention discloses a rosemary extract preparation process, relates to the technical field of rosemary extract preparation methods, and aims to solve the problems of poor physicochemical properties and poor solubilizing effect of an extraction product during preparation of an existing rosemary extract preparation process. The method comprises the following steps: step 1, crushing; step 2, adding water and mixing; step 3, heating and extracting; step 4, carrying out gas-liquid separation; step 5, carrying out peculiar smell adsorption; step 6, carrying out disinfection and sterilization; and step 7, packaging and storing.

Owner:禹州战营迷迭香生物科技有限公司

Steel ball racking machine

ActiveCN102910301BRealize automatic packagingReduce labor intensitySolid materialControl systemSteel ball

The invention discloses a steel ball racking machine comprising a rack, a funnel arranged on the rack, an upper valve sealing mechanism, a lower valve sealing mechanism, a racking cylinder, an upper chute, a discharge cylinder, a lower chute, a discharge pipe and a control system, wherein the upper valve sealing mechanism comprises a first supporting plate arranged on the rack, a first driving mechanism is arranged on the first supporting plate, a first transmission mechanism is connected to the first driving mechanism, a first propelling mechanism is connected to the first transmission mechanism, and an upper valve is connected to the first propelling mechanism; the discharge cylinder is arranged on the bottom surface of a second supporting plate, a discharge hole is arranged in the discharge cylinder, a material storage cavity is communicated with the discharge hole, and a lower valve can simultaneously seal the outlet of the material storage cavity and the inlet of the discharge hole; the lower chute is arranged on the discharge cylinder, the lower valve is located in the lower chute, and the inlet of the discharge hole is located in the bottom surface of the lower chute; the discharge pipe is connected with the discharge cylinder; and the control system is electrically connected with the first driving mechanism and a second driving mechanism.

Owner:中山市乾润精密钢球制造有限公司

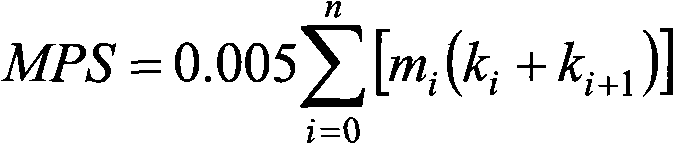

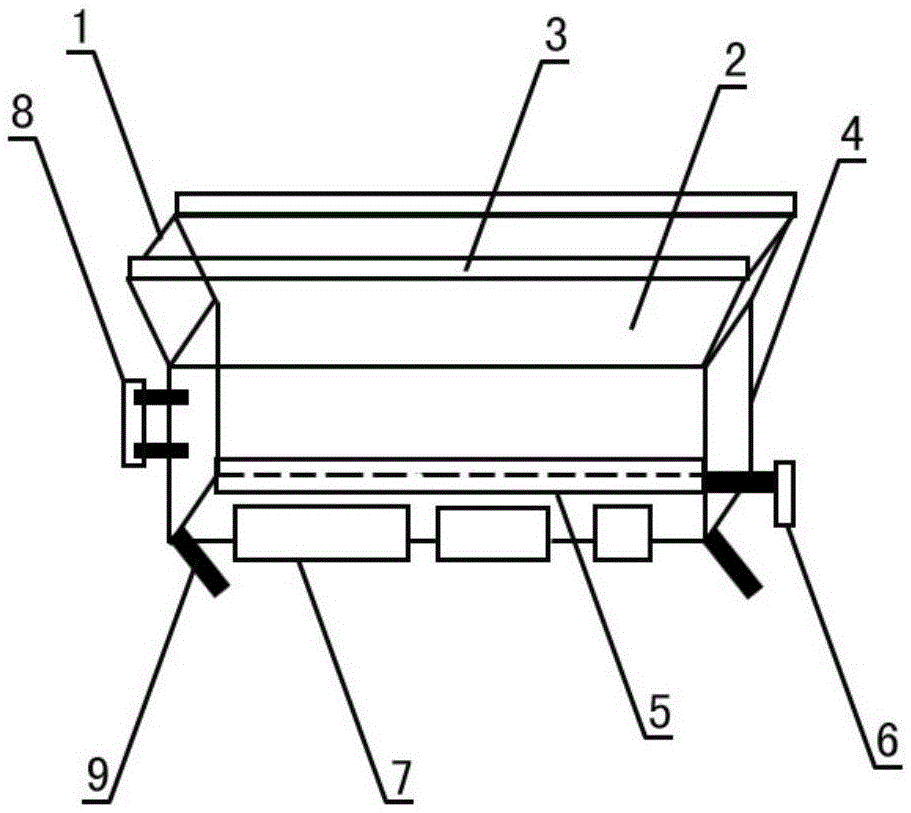

Regulable blanking device

The invention relates to a regulable blanking device, comprising a rack body (1); the whole rack body (1) is designed into a three-section structure, the upper part of the rack body is provided with a material guide groove device (2) and a clamp plate structure (3), the middle of the rack body is a hollow cabin device (4) which is connected with a regulation structure and comprises a paging shaft device (5) and a hand wheel device (6), and the lower part of a shaft body respectively corresponds to blanking groove devices (7) having different sizes of rabbets; when the regulable blanking device is used, a bag mouth is fixed at the upper part of the rack body (1); the different rabbets can be selected according to the needed amount of material; a handrail device (8) arranged at the left side of the rack body (1) can be held by an operator; the bottom of the rack body (1) is provided with corner support modules (9); the regulable blanking device is designed into a folded structure, thus being convenient and fast to take and use; the regulable blanking device is simple in appearance structure and design, and is capable of effectively enabling particle material to be safe in split charging and avoiding the waste phenomenon caused by leakage at the bag mouth; furthermore, the regulable blanking device is high in stability and safe in assembly and disassembly, and has stronger practicability.

Owner:ANHUI BAOYU ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com