Regulable blanking device

A technology of blanking and shaft device, which is applied in packaging and other directions, and can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

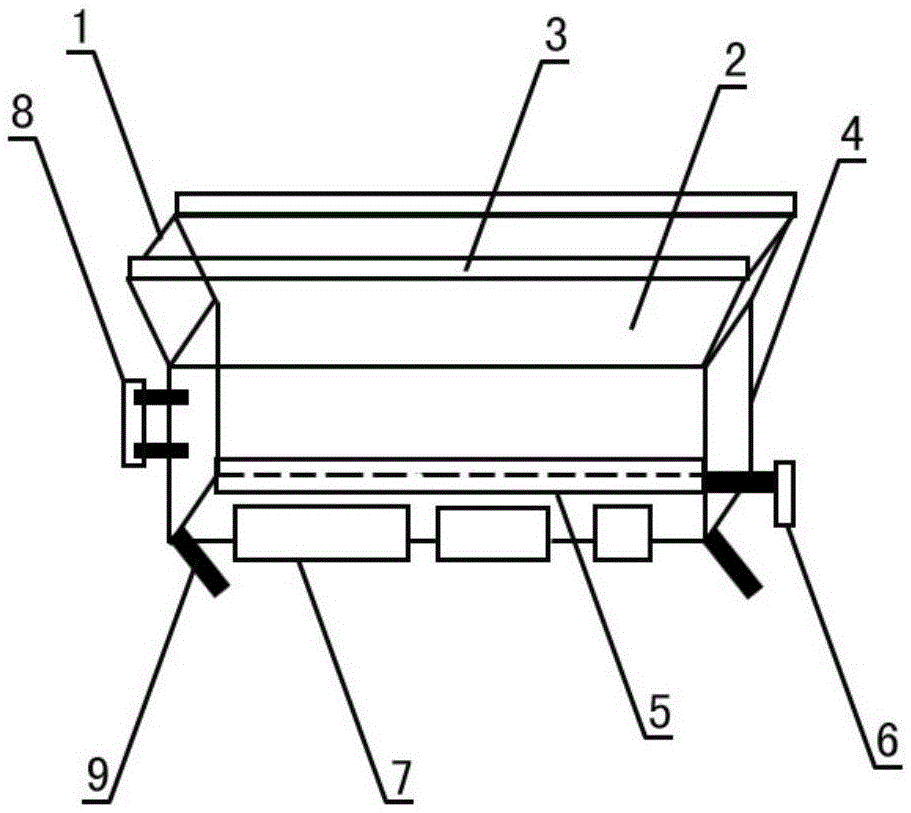

[0012] Embodiment: as shown in the accompanying drawing. An adjustable unloading device, comprising a frame body (1), the frame body (1) is designed as a three-section structure, the upper part is provided with a material introduction trough device (2), a splint structure (3), and the middle part is a hollow cabin device (4) It is connected with the control structure, including the paging shaft device (5) and the manual wheel device (6). The lower part of the shaft body corresponds to the chute device (7) with different sizes of slots. When in use, the bag opening is fixed on the frame. Body (1) top, select different notches according to the amount of material required.

[0013] An adjustable unloading device. An armrest device (8) is provided on the left side of the frame body (1) to facilitate the support of the operator.

[0014] An adjustable unloading device, the bottom of the frame body (1) is provided with a corner module (9), which is designed in a folding structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com