Non-oxidiser percarbonate particles

A technology of sodium percarbonate and particles, which is applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, non-metallic elements, etc. It can solve the problems affecting the washing performance of preparations, etc. To achieve the effect of safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

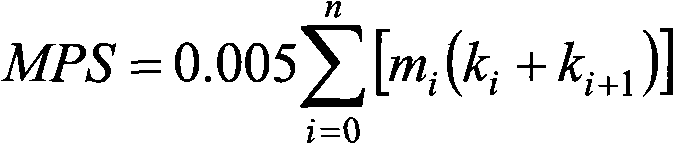

Method used

Image

Examples

Embodiment Construction

[0069] In a Glatt laboratory spray dryer with approximately 40% Na 2 CO 3 1600 g of uncoated sodium percarbonate (PCS) having an average particle size of about 700 μm was coated.

[0070] Raw material: 1600g PCS

[0071] Coating agent: Na 2 CO 3

[0072] Coating degree: 40%

[0073] Coating weight: 915g Na 2 CO 3

[0074] Concentration of coating solution: 25%

[0075] Air pressure: 2.5 bar

[0076] Spray pressure: 1.8 bar

[0077] Temperature under the bed: 100°C-110°C

[0078] Temperature above the bed: 50°C-55°C

[0079] Coating time: about 90 minutes

[0080] Drying time: 9 minutes

[0081] Drying temperature: 70°C

[0082] The coated PCS had an AvOx of 7.53% and a water content of 6.4% measured with the Karl Fischer method (using Aqua 40 from Jena-Analytik at a constant value of 70°C).

[0083] Other samples were post-dried to lower moisture contents.

[0084] Prepare four samples:

[0085] Sample 1:

[0086] Avox is 7.53%, water content: 6.4%

[0087]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com