Method for split packaging of n-butyllithium solution

A n-butyllithium solution technology, applied in liquid bottling, packaging, liquid filling, etc., can solve the problems of danger, easy hydrolysis, concentration reduction, etc., and achieve the effect of safe packaging process and no reduction in product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

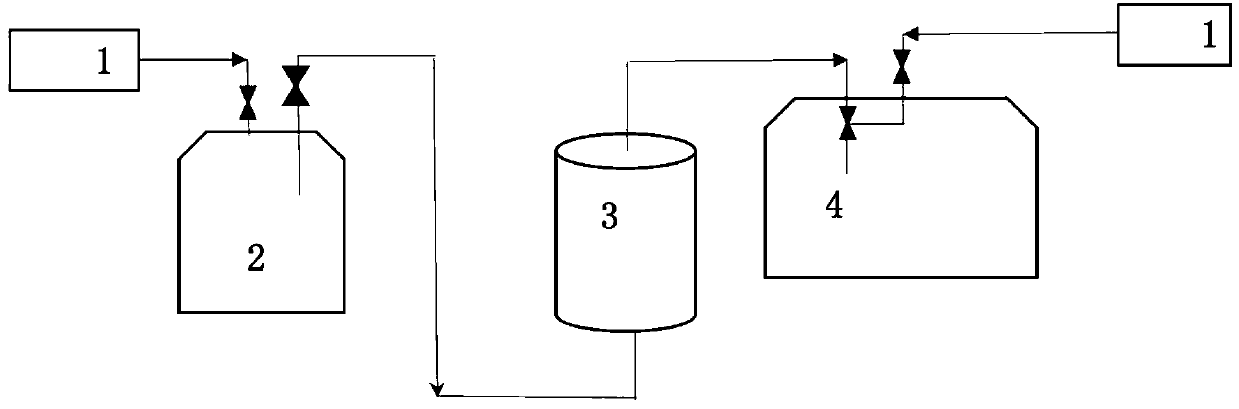

[0019] Such as figure 1 As shown, the present invention adopts the following technical solutions, including two steps.

[0020] Step 1, subpackage of n-butyllithium solution.

[0021] Step 1-1. Pressurize the inert gas from the gas phase (gas phase valve) of the 100L steel cylinder containing n-butyllithium solution. The liquid flows out through the liquid phase valve and is filtered through a stainless steel filter. After filtering, it is connected to the glove box. The gas is distributed in the glove box, and the n-butyl solution is transferred to the reagent bottle through pipeline transfer.

[0022] Step 1-2. Buckle the diaphragm pad in the inner bottle cap (reagent bottle), manually buckle the inner bottle cap on the mouth of the reagent bottle, tighten it until it cannot be twisted, and use a torque wrench to reinforce it until it cannot be turned, and then use it Screw the outer cover onto the inner cover by hand until it cannot be twisted; after dispensing, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com