A packaging method suitable for steel coils with a width of 30-70mm

A packaging method and roll material technology, which is applied to packaging, binding materials, and parts of binding machinery, etc., can solve problems such as hoisting and sub-roll packaging, radial strapping packaging difficulties, hidden dangers of packaging methods and methods, etc., and achieve packaging safety Reliability, increase productivity, and increase competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] A packing method suitable for steel coils with a width of 30-70mm is characterized in that it includes the following steps:

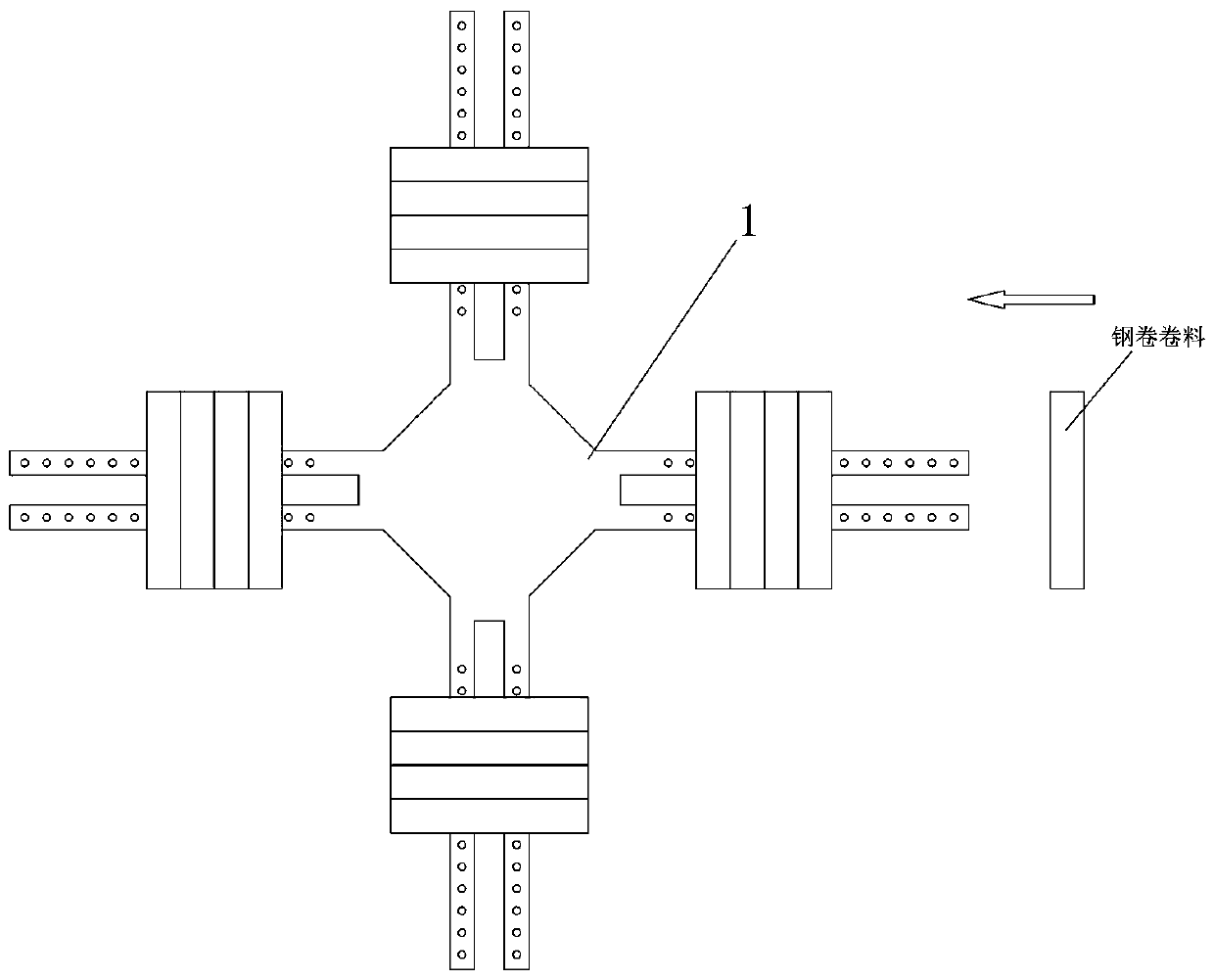

[0023] a) Unload the steel coil material to be packaged from the coiler of the slitting unit to the cross arm 1 of the material rack, and the steel coil coil is as close as possible to the root of the cross arm 1 of the material rack, such as figure 1 shown;

[0024] b) Turn the material to be packaged on the cross arm 1 of the material rack to the east or north direction, so as to facilitate the packaging and lifting of the packaging personnel;

[0025] c) Check whether the edges of the steel coils to be packed are neat, whether the inner and outer coils of the steel coils are tightened tightly, and if there is any abnormality, it should be reported to the operator on duty immediately;

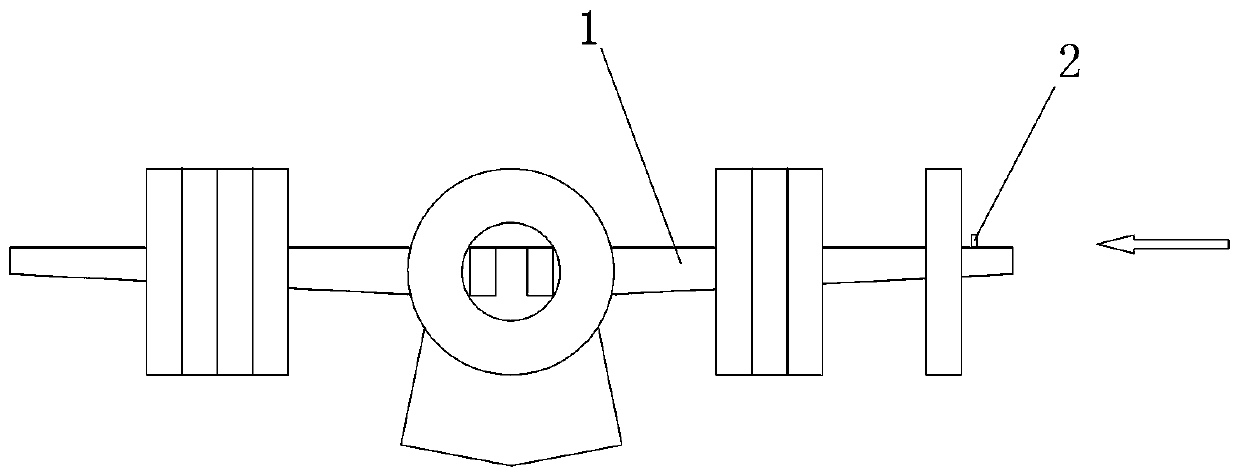

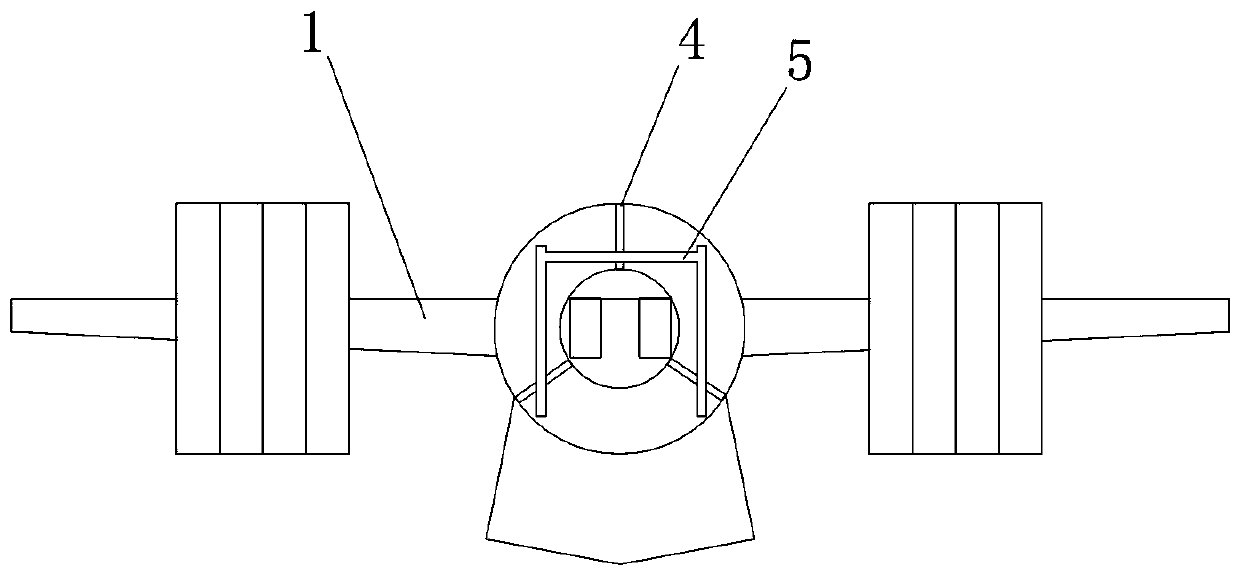

[0026] d) Before packaging, insert two retaining rods 2 into the screw holes at the end of the cross arm 1 of the material rack to prevent the steel coil from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com