Antiseptic composition waterborne preparation and method for preparing same

A bactericide composition, water-based technology, applied in the microemulsion of tristrobin and tebuconazole composition microemulsion, suspoemulsion and its manufacture, bactericide composition water-based preparation, water emulsion field, can solve the problem of not yet seen water-based Dosage reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

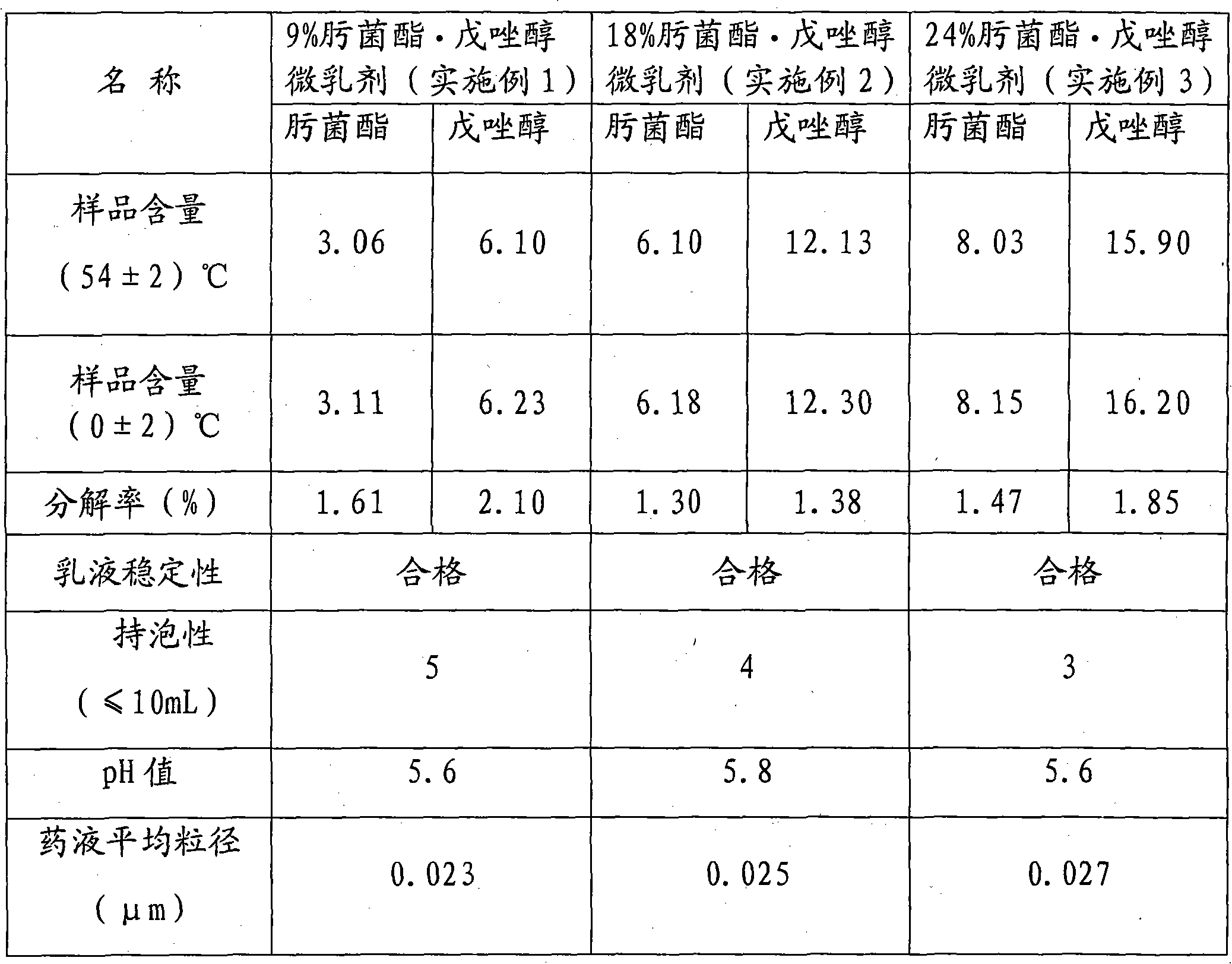

[0069] Example 1 9% trifloxystrobin tebuconazole microemulsion

[0070] The mass percentages of each raw material are as follows: 32 kilograms of trifloxystrobin (95%), 64 kilograms of tebuconazole (95%), 100 kilograms of turpentine, 50 kilograms of ethanol, 15 kilograms of penetrant T15, 35 kilograms of Nongru No. 601, Tween 8030 kg, calcium dodecylbenzenesulfonate 40 kg, water 634 kg; during production, trifloxystrobin, tebuconazole, turpentine, ethanol, penetrant T, Nongru No. 601, Tween 80, ten Add calcium dialkylbenzenesulfonate into the reaction kettle, stir at 1000 rpm for 20 minutes, fully dissolve to form an oil phase, slowly add water, stir for 15 minutes, and become a uniform and transparent liquid, that is, 9% trifloxystrobin Tebuconazole microemulsion.

Embodiment 2

[0071] Example 2 18% trifloxystrobin tebuconazole microemulsion

[0072] Each raw material mass percentage is as follows: 64 kilograms of trifloxystrobin former medicine (95%), 127 kilograms of tebuconazole former medicine (95%), 80 kilograms of turpentine, 40 kilograms of methyl salicylate, 50 kilograms of isopropanol, N- Methylpyrrolidone 30kg, water-soluble azone 15kg, Nongru No. 701 30kg, OP-15 80 50kg, calcium dodecylbenzenesulfonate 40kg, sodium dodecylbenzenesulfonate 20, water 454 kg; during production, trifloxystrobin, tebuconazole, turpentine, methyl salicylate, isopropanol, N-methylpyrrolidone, water-soluble azone, Nongru No. 701, OP-15, dodecyl Add calcium benzenesulfonate and sodium dodecylbenzenesulfonate into the reaction kettle, stir at 2000 rpm for 20 minutes, fully dissolve to form an oil phase, slowly add water, stir for 15 minutes, and become a uniform transparent liquid, namely 18% trifloxystrobin·tebuconazole microemulsion was obtained.

Embodiment 3

[0073] Example 3 24% trifloxystrobin tebuconazole microemulsion

[0074] The mass percentages of each raw material are as follows: 85 kilograms of trifloxystrobin (95%), 169 kilograms of tebuconazole (95%), 110 kilograms of turpentine, 40 kilograms of methyl salicylate, 50 kilograms of acetone, and 30 kilograms of undecyl alcohol. Kilogram, water-soluble azone 15kg, JFC 10, EL-60 40kg, Nongru No. 403 20kg, Nongru No. 34 50kg, calcium dodecylbenzenesulfonate 40kg, sodium lauryl sulfate 30kg , 454 kg of water. During production, trifloxystrobin, tebuconazole, turpentine, methyl salicylate, acetone, undecyl alcohol, water-soluble azone, JFC, EL-60, Nongru No. 403, Nongru No. 34, dodecane Calcium benzenesulfonate and sodium dodecylbenzenesulfonate were added to the reaction kettle, stirred at 2000 rpm for 25 minutes, fully dissolved to form an oil phase, water was slowly added, and stirred for 25 minutes to become a uniform transparent liquid. That is, 24% trifloxystrobin·tebuco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com