Wooden clothes hanger back polishing mechanism and wooden clothes hanger back polishing device having same

A back-polishing and coat-hanger technology is applied in the direction of grinding machine parts, surface-polished machine tools, manufacturing tools, etc., and can solve the problems of inability to guarantee the consistent shape of wooden hangers, prolonging the working time of a single operator, and increasing production costs, etc. Achieve the effect of ensuring work continuity, reducing labor input and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

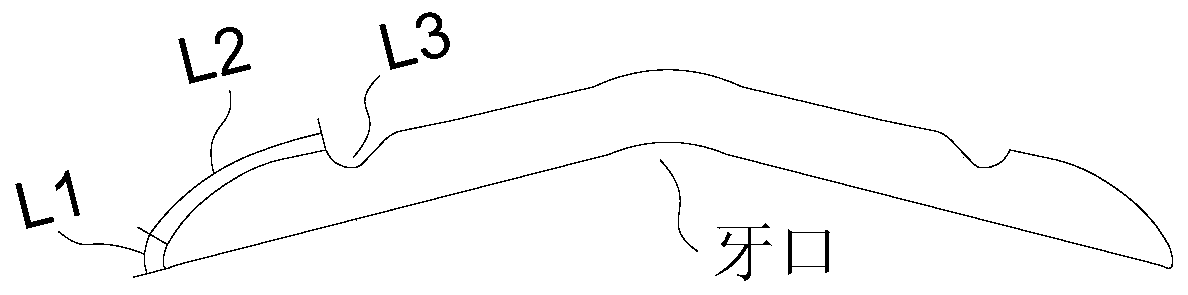

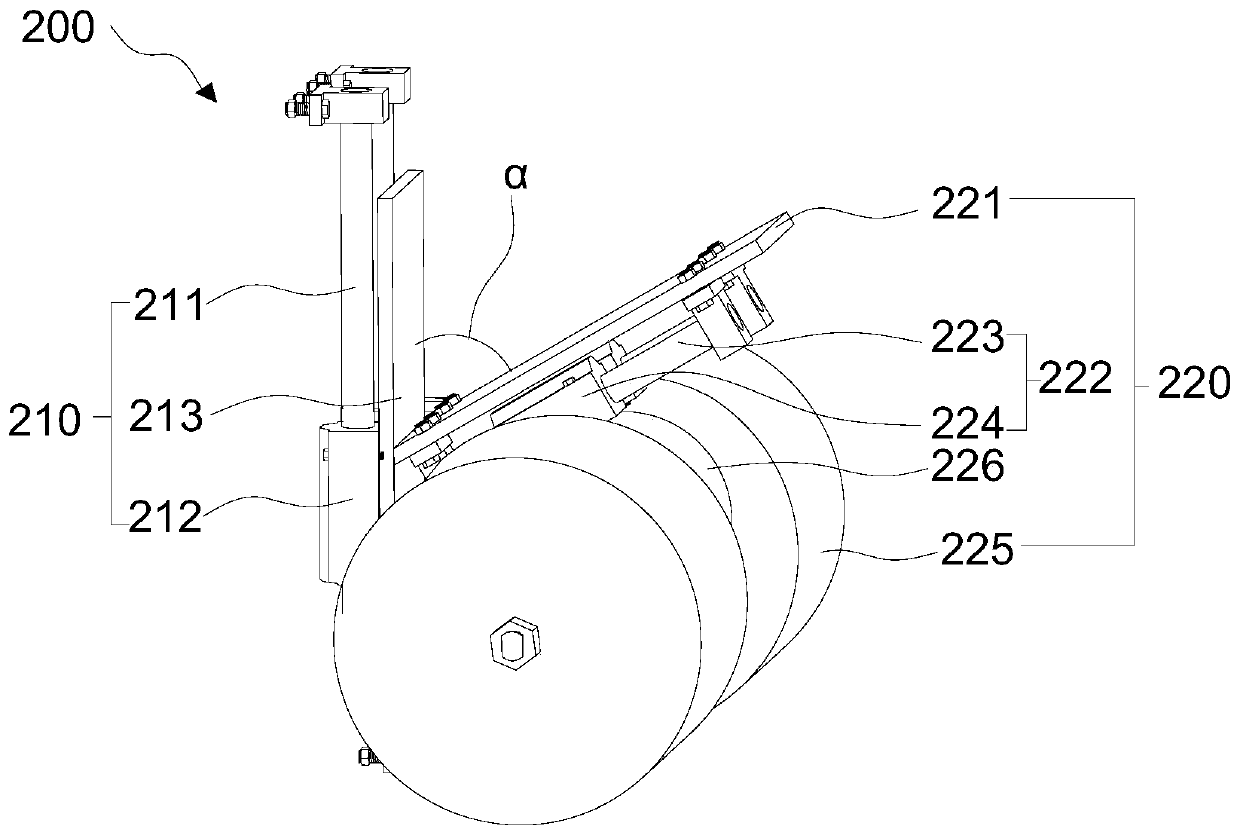

[0034] Such as figure 1 and figure 2 As shown, this embodiment provides a wooden hanger back polishing mechanism 200 for polishing the second arc surface L2 of the back of the wooden hanger. The wooden hanger back polishing mechanism 200 includes a lifting component 210 and a polishing component 220 . The lifting assembly 210 includes a lifting driver and a mounting plate 213 , the lifting driving component is fixedly connected to the mounting plate 213 to drive the mounting plate 213 to lift.

[0035] The polishing assembly 220 includes a guide plate 221 , a reciprocating displacement member 222 and a polishing member. One end of the guide plate 221 is fixedly connected to the installation plate 213, and the other end of the guide plate 221 extends away from the installation plate 213. The guide plate 221 is inclined relative to the installation plate 213, and the angle between the guide plate 221 and the installation plate 213 is α , in this embodiment, the angle of α is...

Embodiment 2

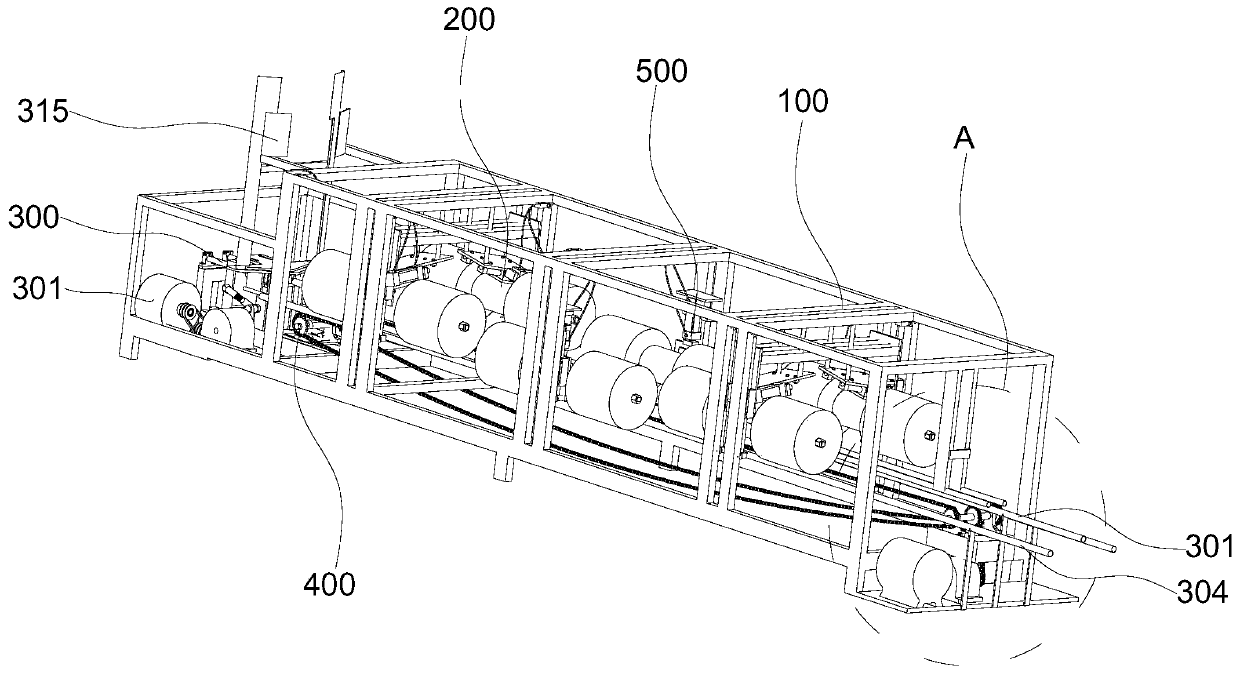

[0043] Such as Figure 1 to Figure 8 As shown, this embodiment provides a wooden clothes hanger back polishing device, including a rack body 100 , a transmission mechanism 300 , a wooden clothes hanger back polishing mechanism 200 , a vertical polishing mechanism 500 and a feeding mechanism 310 .

[0044] The transmission mechanism 300 is installed on the frame body 100 for transmitting wooden clothes hangers; the wooden clothes hanger back polishing mechanism 200 and the vertical polishing mechanism 500 are installed on the frame body 100 at intervals, wherein the wooden clothes hanger back polishing mechanism 200 is used for To polish the second arc surface L2 of the wooden hanger on the transmission mechanism 300, the vertical polishing mechanism 500 is used to polish the first arc surface L1 of the wooden hanger on the transmission mechanism 300; the feeding mechanism 310 is installed on the transmission mechanism 300 One end, to feed on the conveying mechanism 300.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com