A kind of reverse fluid steering conveying device

A conveying device and reverse fluid technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of heating, metering pumps without maintenance-free function, and difficult maintenance, so as to ensure corrosion resistance , reliable operation, strong corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

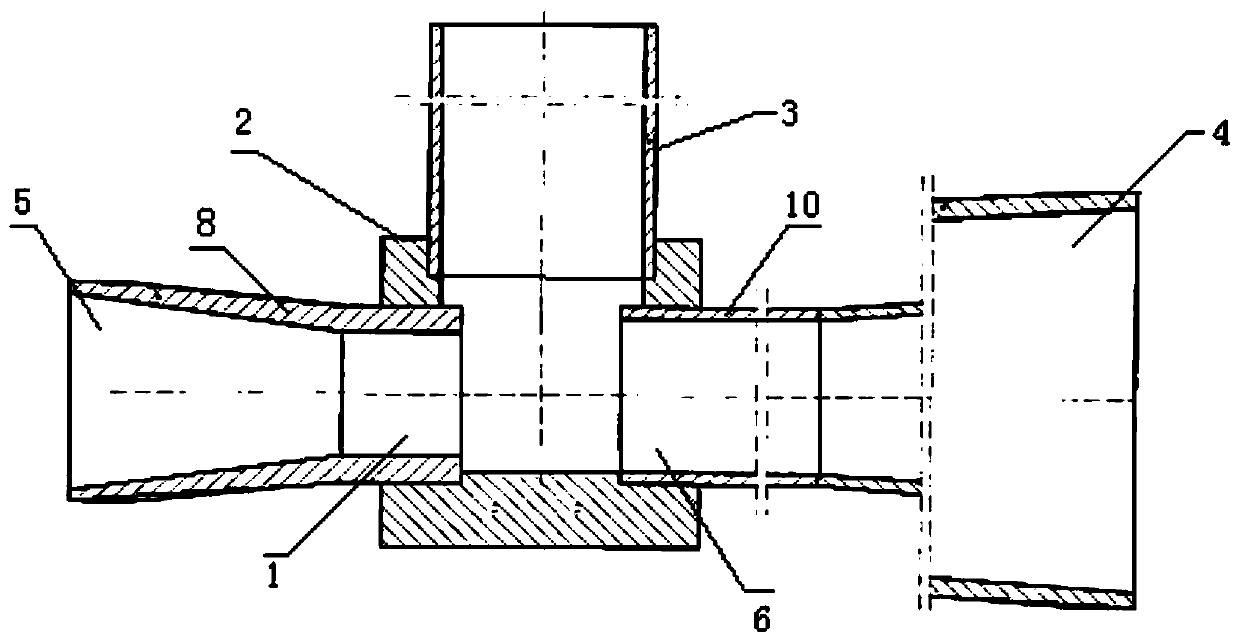

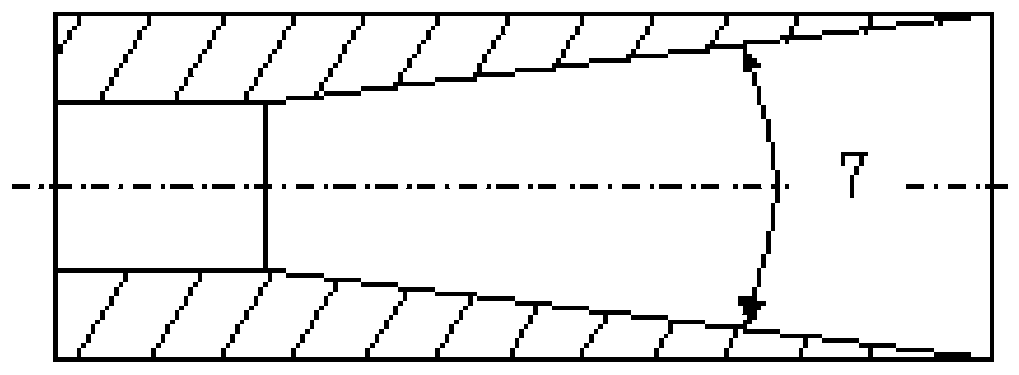

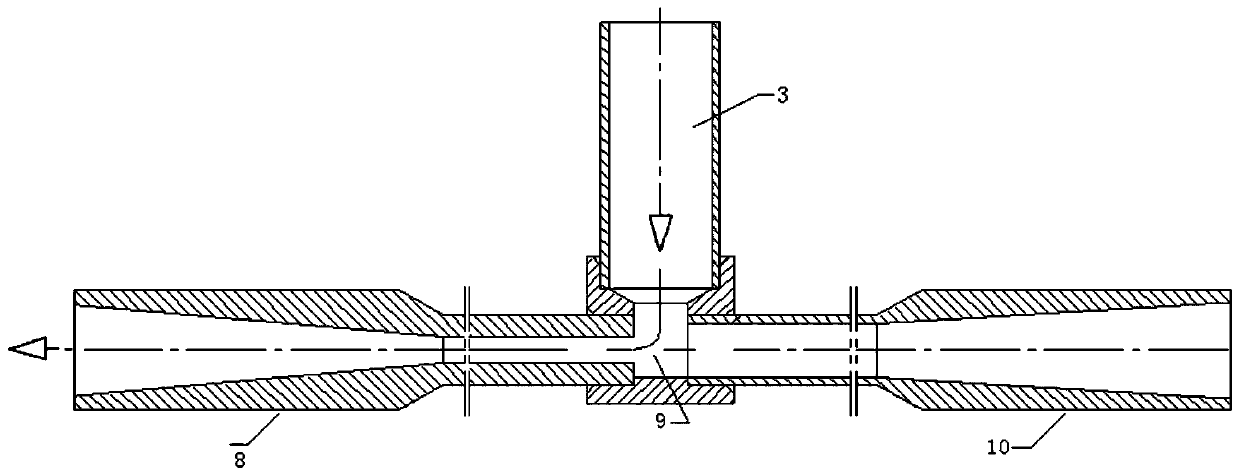

[0045] Taking the diameter of the driving nozzle inlet 1 as an example of 10 mm, the diameter of the diffuser inlet 6 is 12.5 mm, the drainage gap 9 is 12.5 mm, the diameter of the drainage tube 3 and the diameter of the diffuser outlet 4 are both 31 mm, and the diameter of the driving nozzle outlet 5 is 31 mm.

Embodiment 2

[0047] Taking the diameter of the driving nozzle inlet 1 as an example of 25mm, the diameter of the diffuser inlet 6 is 32.0mm, the drainage gap 9 is 32.0mm, the diameter of the drainage tube 3 and the diameter of the diffuser outlet 4 are both 80.0mm, and the diameter of the driving nozzle outlet 5 is 80.0mm .

Embodiment 3

[0049] Taking the diameter of the drive nozzle inlet 1 as an example of 32mm, the diameter of the diffuser inlet 6 is 40.0mm, the drainage gap 9 is 40.0mm, the diameter of the drainage tube 3 and the diameter of the diffuser outlet 4 are both 100.0mm, and the diameter of the drive nozzle outlet 5 is 100.0mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com