Light, waterproof and abrasion-resistant EVA material

A lightweight, wear-resistant phase technology, applied in the field of EVA materials, can solve the problems of reduced shear resistance, increased product process time and process costs, loss of softness and elasticity of vinyl acetate copolymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

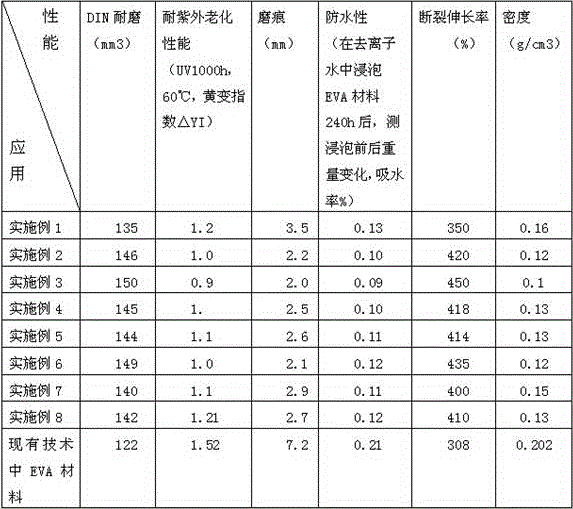

Examples

Embodiment 1

[0026] A light wear-resistant and waterproof EVA material, comprising the following materials in parts by weight, 30 parts of EVA, 10 parts of natural rubber, 1 part of polyvinylpyrrolidone, 10 parts of wear-resistant agent, and 3 parts of foaming agent;

[0027] The VA weight percentage contained in the EVA is 40%.

[0028] The EVA material in the present embodiment adopts the following steps to prepare:

[0029] a. Heat EVA and natural rubber to molten state respectively to obtain EVA melt and natural rubber melt. The EVA and natural rubber in the melt state can flow and can penetrate each other when mixed together. Because EVA and natural rubber contain Unsaturated bonds, part of the EVA and natural rubber in the melt state will also undergo polymerization reactions to increase the degree of cross-linking between EVA and natural rubber;

[0030] B, under constant temperature, EVA melt, natural rubber melt, blowing agent, wear-resisting agent and polyvinylpyrrolidone are mi...

Embodiment 2

[0033] A light wear-resistant and waterproof EVA material, comprising the following materials in parts by weight, 45 parts of EVA, 15 parts of natural rubber, 5 parts of polyvinylpyrrolidone, 15 parts of white carbon black, and 15 parts of hydrogen;

[0034] The EVA containing VA weight percentage is 70%.

[0035]The above-mentioned EVA material is prepared by the following steps: d, heating EVA and natural rubber to a molten state respectively to obtain an EVA melt and a natural rubber melt; Grinding phase is mixed evenly with polyvinylpyrrolidone to obtain a preliminary mixture; f, the preliminary mixture is put into a vacuum airtight container at a constant temperature, and then hydrogen gas is passed into the mixture until the pressure of the airtight container reaches 1.5 atmospheres, keeping 5h; wherein the constant temperature in step e is the same as the constant temperature in step f, which is 160°C, and the constant temperature is a temperature that can make both the...

Embodiment 3

[0038] A light wear-resistant and waterproof EVA material comprises the following materials in parts by weight: 45 parts of EVA, 15 parts of natural rubber, 5 parts of polyvinylpyrrolidone, 30 parts of white carbon black, and 15 parts of hydrogen.

[0039] The EVA containing VA weight percentage is preferably 70%

[0040] The above-mentioned EVA material is prepared by the following steps: d, heating EVA and natural rubber to a molten state respectively to obtain an EVA melt and a natural rubber melt; Grinding phase is mixed evenly with polyvinylpyrrolidone to obtain a preliminary mixture; f, the preliminary mixture is put into a vacuum airtight container at a constant temperature, and then hydrogen gas is passed into the mixture until the pressure of the airtight container reaches 1.5 atmospheres, keeping 5h; wherein the constant temperature in step e is the same as the constant temperature in step f, which is 150°C, and the constant temperature is a temperature that can make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com