Low-temperature after finishing method of textiles

A textile and finishing technology, applied in textiles and papermaking, fiber processing, dry cleaning fiber products, etc., can solve the problems of fabric weight loss, non-biodegradation, large water consumption, etc., to reduce energy consumption and pilling. , the effect of weight loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: For knitwear

[0028] 1. Milling

[0029] a) Bath ratio: 1:25 (medium water level);

[0030] b) Temperature: normal temperature (0°C-20°C);

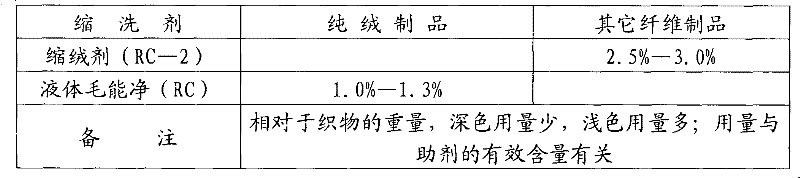

[0031] c) Shrinkage agent

[0032]

[0033] d) Time: In order to pursue a more excellent soft effect, it is recommended to soak for 20 minutes before stirring. There are two ways to choose the stirring time according to the actual situation: use shrinking to make the suede in place in one step, and the turning time depends on the size of the suede. , this situation means that the fabric is soaked in a static state (such as in a pool) when it is soft; the agitation is for the purpose of cleaning, and it takes 3-5 minutes. If the suede is insufficient, it can be made up by agitation when it is soft. This is when the fabric is softened in the washing machine;

[0034] e) Dehydration: high-speed dehydration, strive to minimize the liquid-carrying rate, subject to no foam overflow;

[0035] f) Rinse: rinse with cold ...

Embodiment 2

[0049] Embodiment two: for cloth

[0050] 1. Shrink it

[0051] a) Bath ratio: 1:1 (that is, the weight of water is the same as that of cloth);

[0052] b) Water temperature: normal temperature (0°C-20°C);

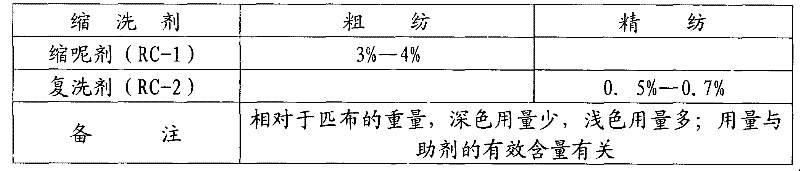

[0053] c) shrinking detergent

[0054]

[0055] d) Time: 30-40 minutes (depending on suede and shrinkage);

[0056] e) Rinsing: 10 minutes;

[0057] f) Dehydration: high-speed dehydration, and strive for the lowest liquid-carrying rate.

[0058] 2. Transfer to drying, ironing and fluffing process

[0059] 6.3 Soft finishing

[0060] a) Bath ratio: about 1:15 (that is, the amount of water should be controlled to just submerge the cloth);

[0061] b) Temperature: normal temperature (0°C-20°C);

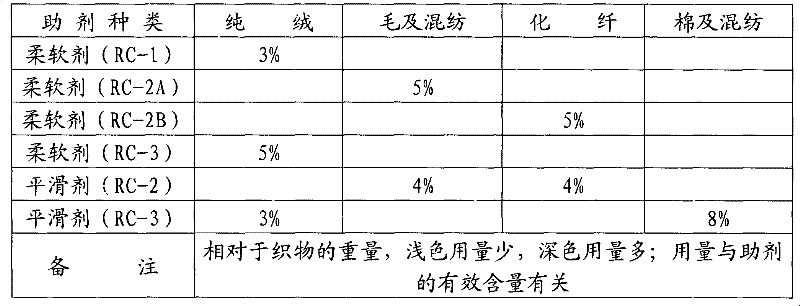

[0062] c) The amount of softener and smoothing agent

[0063]

[0064] d) Time: 30-40 minutes.

[0065] 4. Transfer to the processes of thorn fruit pulling water pattern, dehydration, drying, and debossing.

[0066] 5. Description

[0067]If special functional treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com