125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material

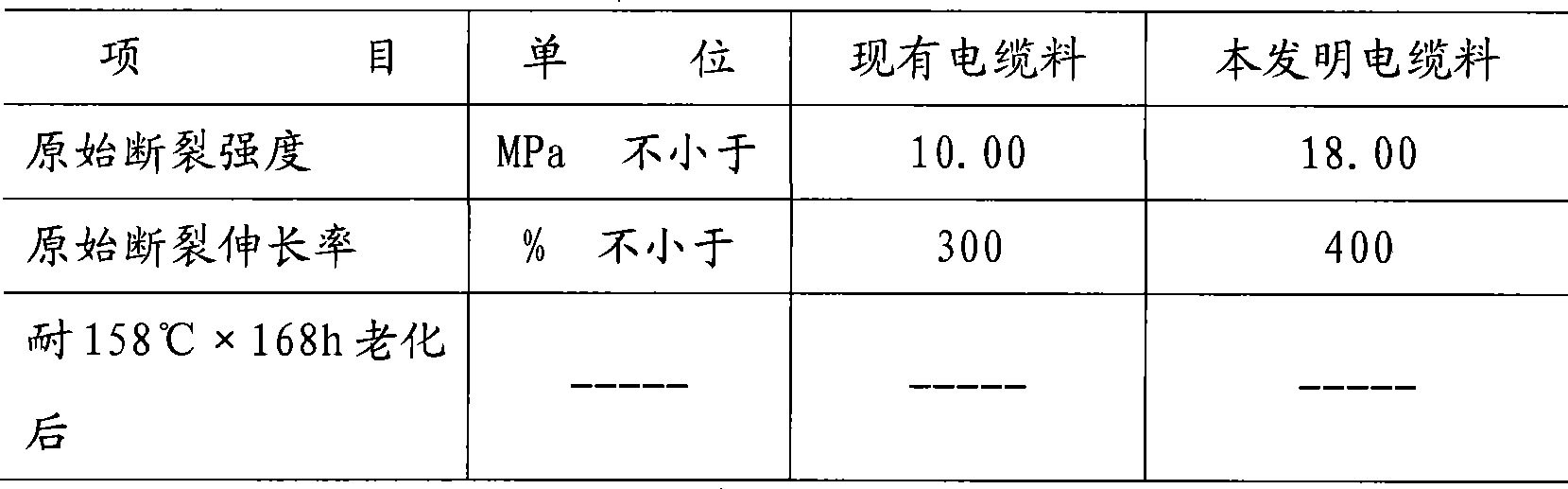

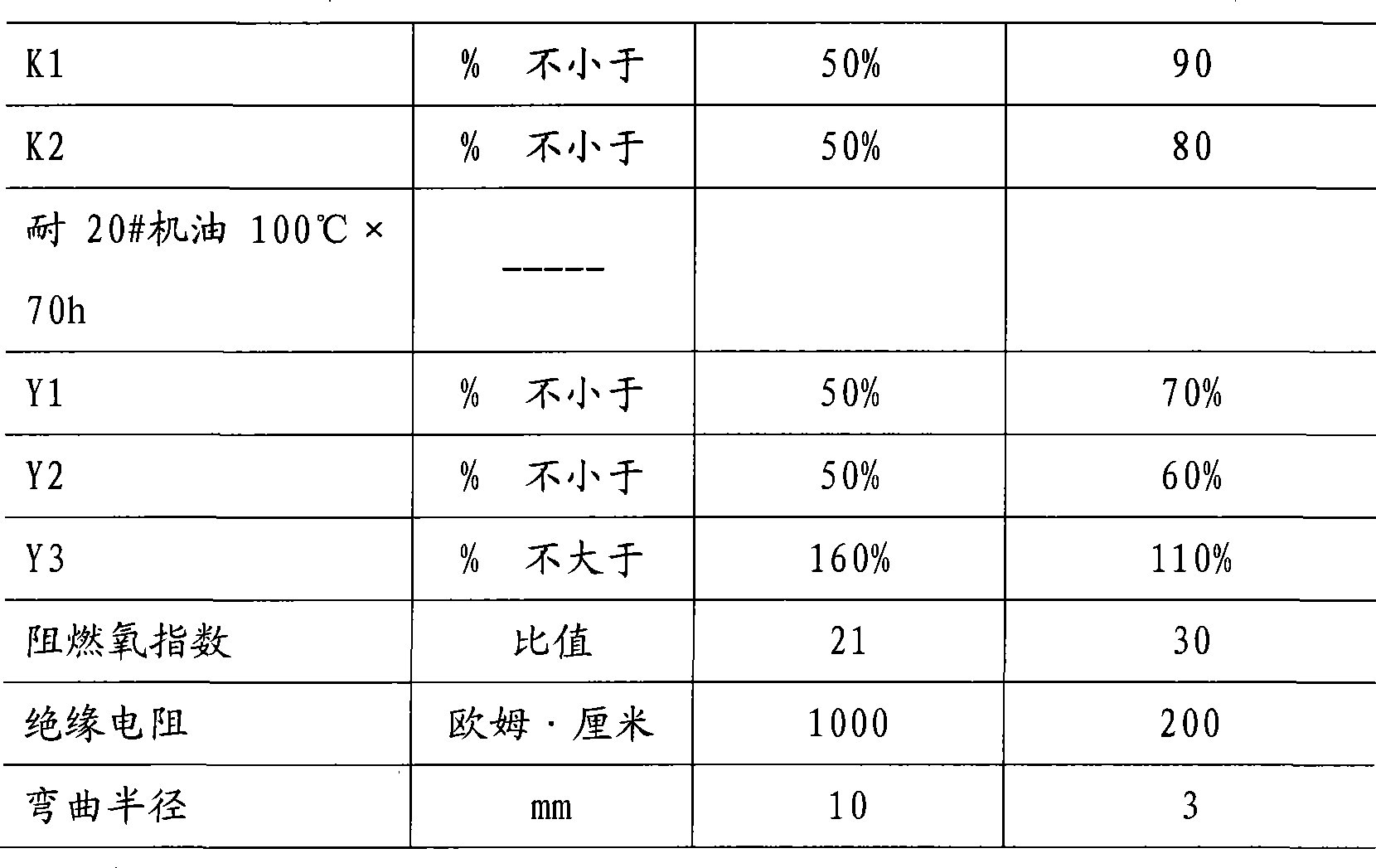

A rubber cable and shielding material technology, which is applied in the field of conductors and insulation shielding cable materials, can solve the problems of softness, shielding performance, high temperature resistance, oil resistance and flame retardancy, etc., and achieve ultra-flexibility, low smoke and halogen-free Effects of environmental protection, superior electrical conductivity, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

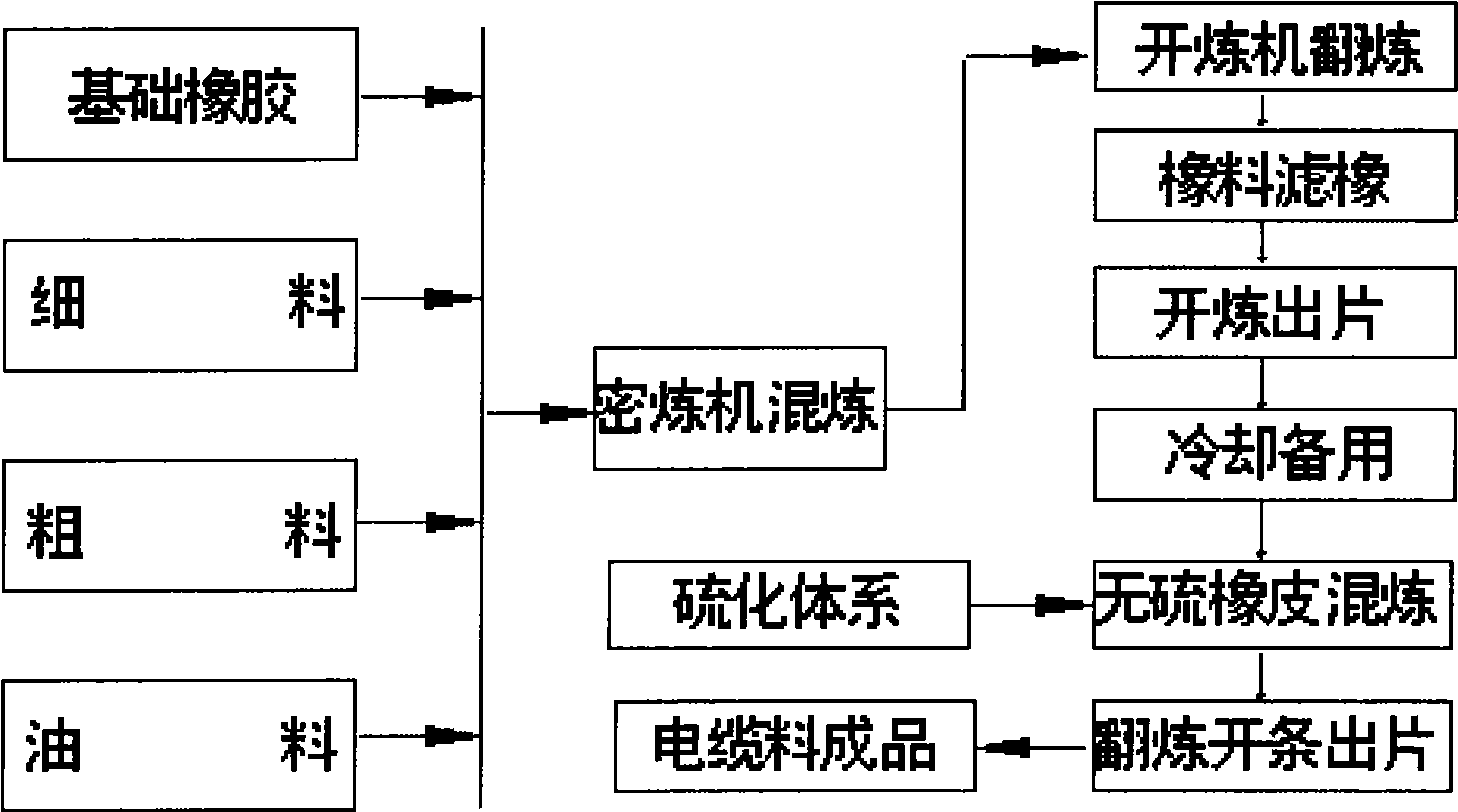

Method used

Image

Examples

Embodiment 1

[0056]First take 300 grams of basic rubber, knead it on a small open mill, add fine materials, stabilizers, anti-aging agents, some conductive carbon black agents and plasticizers, etc. after fully covering the rolls, add the remaining conductive carbon black and plasticizer after basic molding Plasticizer, after adding vulcanizing agent and vulcanizing aids to form, the pitch of the rollers in the small machine is reduced, the rubber is made into thin sheets, and the rubber is made into triangle bags for at least 5 times, and then the sheets are cooled for later use.

Embodiment 2

[0058] Put 27 kg of masticated basic rubber into the internal mixer for 30 seconds to 1 minute, then add anti-aging agent, stabilizer, half of plasticizer, filler, and half of conductive carbon black for about 2 to 3 minutes, then add the rest After 1 to 2 minutes of plasticizer and conductive carbon black, after forming, put the material on the open mill for mixing for about 3 minutes, press the tablet, open the strip and filter the rubber, cool the tablet for later use, the thickness of the tablet is about 2mm, park it for at least After 4 hours, weigh 87.00 kg of unvulcanized rubber and put it into the internal mixer for mixing for about 3 minutes, then add 3.00 kg of vulcanizing agent and vulcanizing aid for 30 seconds to 1 minute. Afterwards, the strips are turned and rolled out for cooling and standby. The thickness of the strips is 2.00mm and the width is 180-250mm.

[0059] Embodiment formula table 2

[0060]

[0061] Remove a certain amount of rubber material, vul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com