Environment-friendly deep nano drainage agent for tight gas well and preparation method of environment-friendly deep nano drainage agent

An environmentally friendly, tight gas technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large particle size variation, short drainage validity period, reservoir damage, etc., and it is easy to achieve process conditions. , The effect of reducing water lock damage and low surface interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An environment-friendly deep nano-drainage agent for dense gas wells according to the present invention includes oil phase, emulsifier, co-emulsion agent, electrolyte and water; the components are as follows in terms of mass percentage: oil phase 15-30%, emulsifier 6-12% %, 3-7% of low-molecular-weight alcohols for emulsion aids, 0.3-1.2% for low-molecular-weight organic acids for emulsion aids, 4-12% for electrolytes, and the rest is water.

[0041] Further, the oil phase is amino polyether modified silicone oil which is a milky white solid with an ammonia value of 0.318-0.596 mmol / g.

[0042]Further, the polyether-modified silicone oil is amino-terminated polyether-modified amino silicone oil, side-chain polyether-modified amino silicone oil, end-side polyether-modified amino silicone oil or a mixture of both.

[0043] Further, the emulsifier is a nonionic surfactant selected from octylphenol polyoxyethylene ether (OP-15), fatty alcohol polyoxyethylene ether (AEO-15),...

Embodiment 2

[0064] At room temperature, put 20g of amino polyether modified silicone oil into a 500mL beaker, and add 8g of octylphenol polyoxyethylene ether (OP-15) and 6g of glycerol into the beaker, and stir at a low speed (500r / min) for 25min ; Then add 10g of distilled water in the total amount of water, continue to stir at 500r / min for 10min; add 0.6g of acetic acid emulsifier, continue to stir at 500r / min for 25min; finally add 6gNaCl and 70g of distilled water, continue to stir at 500r / min for 25min, room temperature Stand still for 60 minutes to get the environment-friendly nanoemulsion drainage agent.

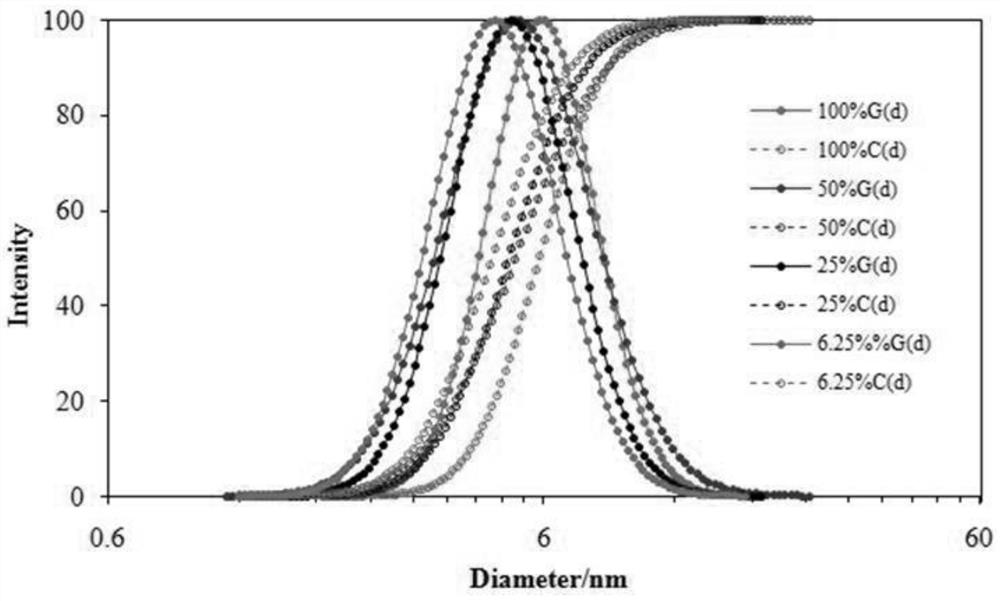

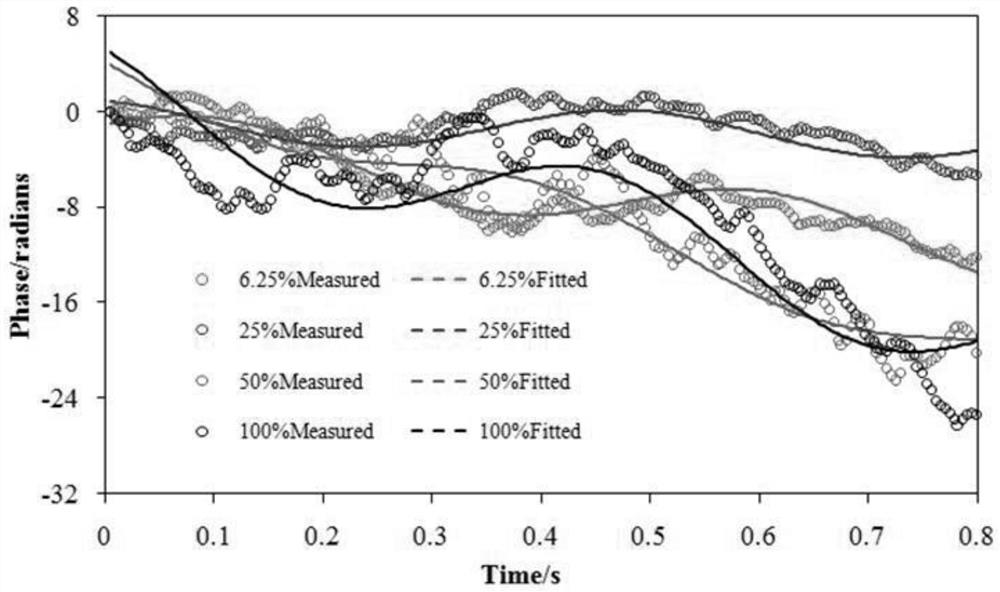

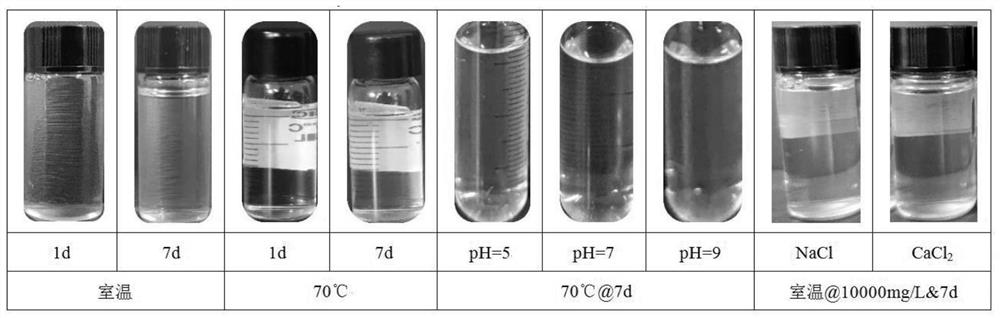

[0065] For the particle size and Zeta potential of the environment-friendly nanoemulsion drainage agent, see figure 1 and figure 2 , the appearance of the environment-friendly nanoemulsion prepared under different conditions after draining and standing for 1d and 7d can be seen image 3 , biotoxicity test see Figure 4 , see Table 1 for biodegradability evaluation, see Figure...

Embodiment 3

[0073] At room temperature, put 20g of amino polyether modified silicone oil into a 500mL beaker, and add 10g of fatty alcohol polyoxyethylene ether (AEO-15) and 5g of ethylene glycol into the beaker, and stir at a low speed (500r / min) for 25min; Then add 10g of distilled water in total and continue to stir at 500r / min for 10min; add 0.7g of propionic acid emulsifier and continue to stir at 500r / min for 25min; finally add 4g of KCl and 70g of distilled water and continue to stir at 500r / min for 25min at room temperature Stand still for 60 minutes to get the environment-friendly nanoemulsion drainage agent.

[0074] The particle size distribution of the environment-friendly nanoemulsion drainage agent is shown in Figure 10, and the performance parameters are shown in Table 3.

[0075] Table 3 Statistical table of performance parameters of environment-friendly nanoemulsion drainage agent

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com