Making method of single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric

A super-hydrophobic, single-sided technology, applied in the fields of plant fibers, textiles and papermaking, ultrasonic/sonic fiber processing, etc., can solve the problems of poor control of the amount of liquid carried, easy infiltration, complicated processes, etc., and achieves simple and feasible technology. The effect of good operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

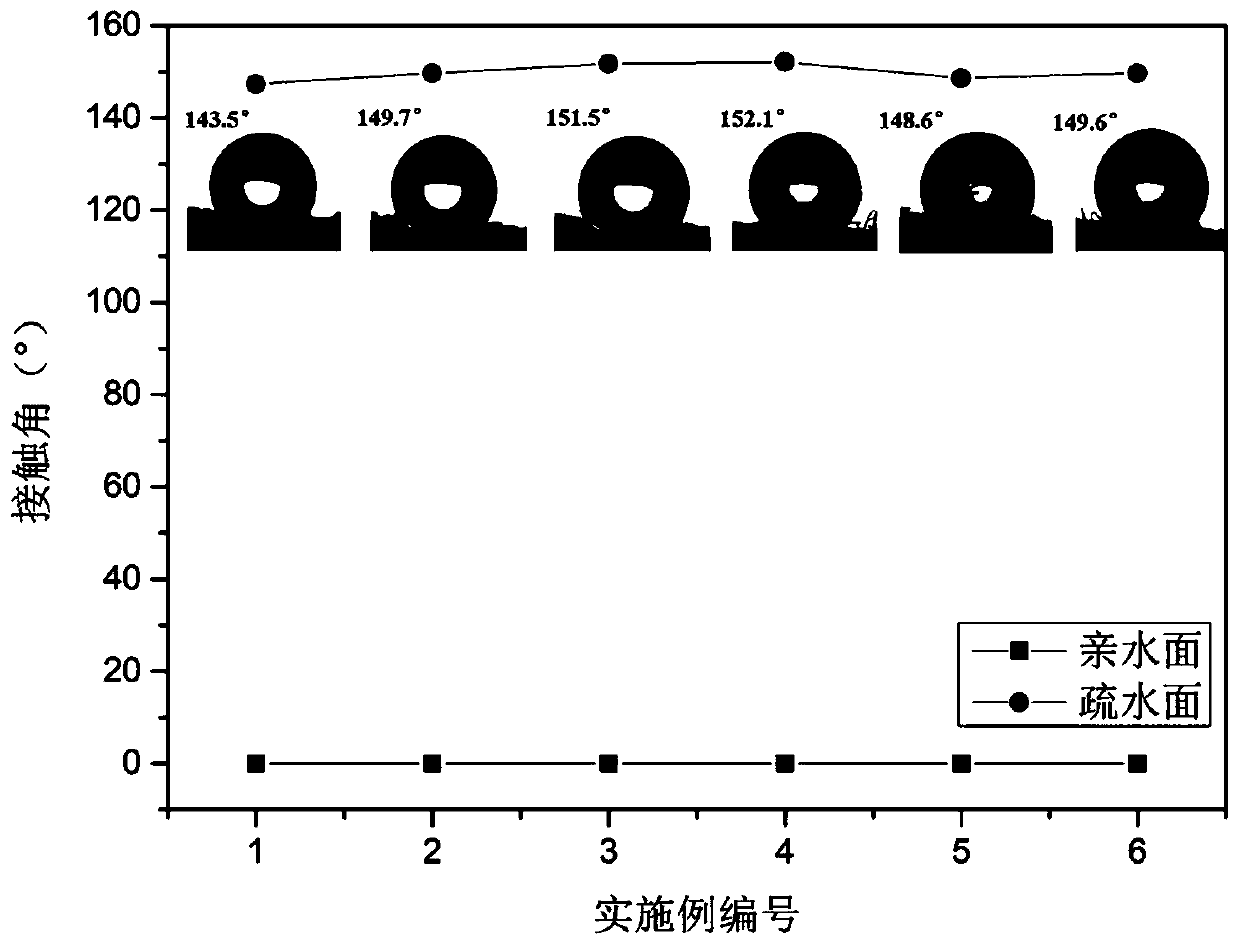

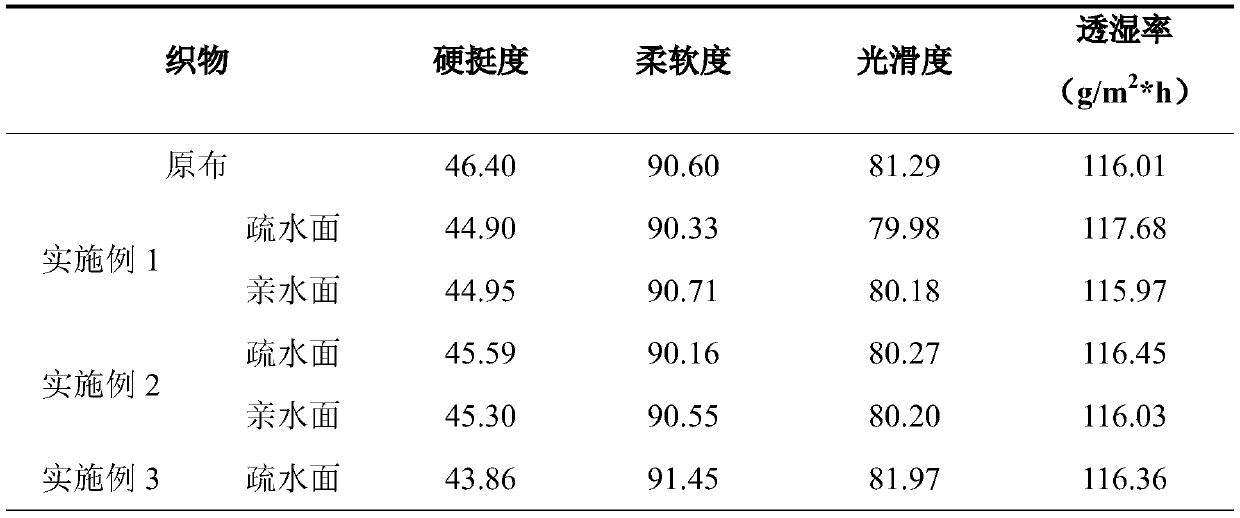

Embodiment 1

[0035] A kind of preparation method of single-sided super-hydrophobic single-sided hydrophilic Janus type fabric, concrete steps are as follows:

[0036] (1) Take a 20cm×20cm white knitted cotton fabric, wash it with 2g / L 209 detergent at 40°C for 5min, wash it with cold water, and dry it at 80°C;

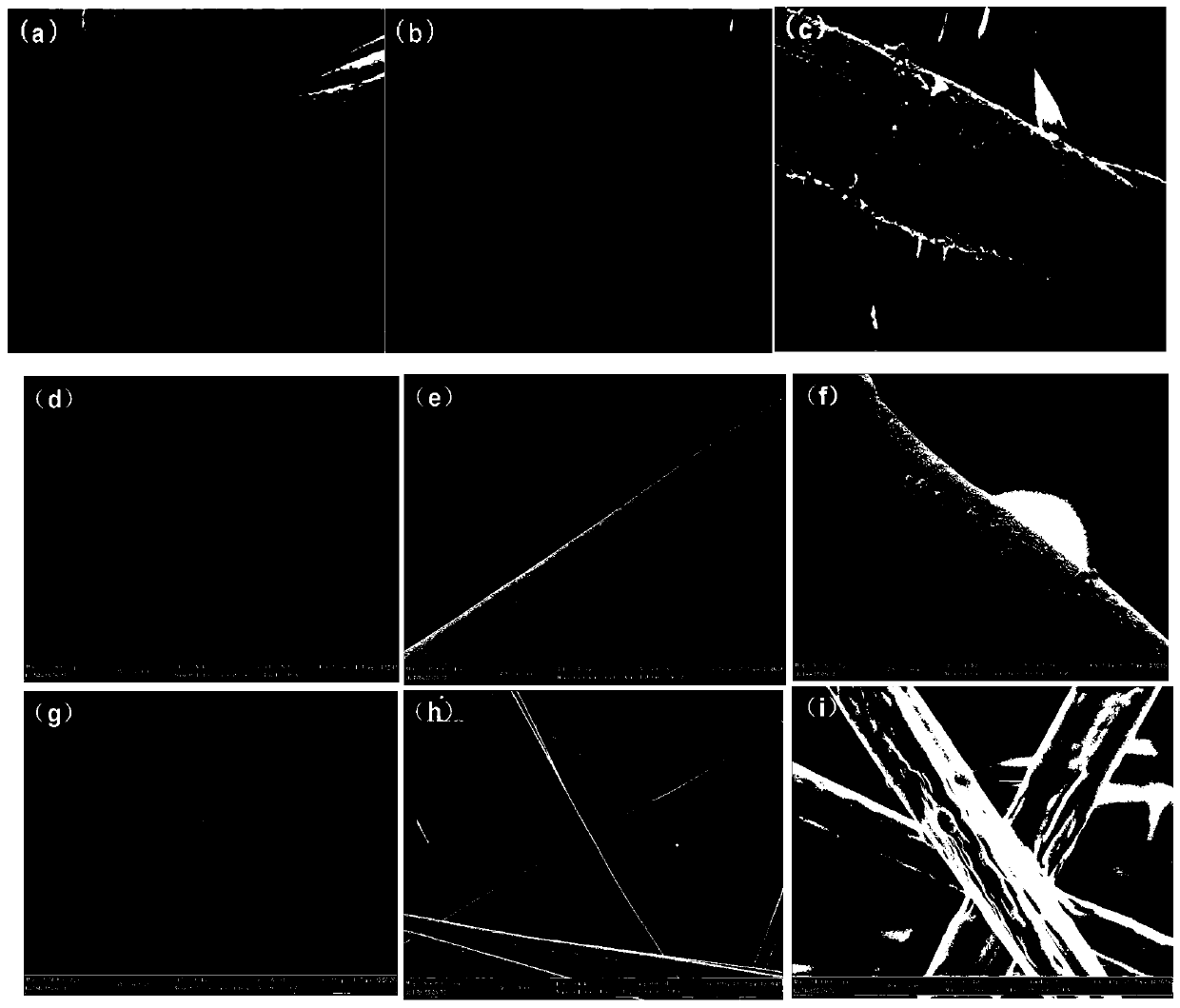

[0037] (2) Attach the cotton fabric to a 22cm×22cm flat thin plastic plate, expose one side of it to the reaction chamber, take 100ml of D4 monomer and add it to the Erlenmeyer flask connected to the cold plasma, and heat it in a water bath at 85°C;

[0038] (3) Hang the cotton fabric protected on one side on the glass rod with plastic clips, put it in the cold plasma reaction chamber, vacuumize, and pass O when the pressure drops below 5Pa 2 , after two gas cycles, adjust the valve, keep the pressure at a stable value of 20Pa, and then turn on the cold plasma radio frequency button to treat the cotton fabric, the time is 2min, and the power is 60W;

[0039] (4) After the discharg...

Embodiment 2

[0042] A kind of preparation method of single-sided super-hydrophobic single-sided hydrophilic Janus type fabric, concrete steps are as follows:

[0043] (1) Take a 20cm×20cm white knitted cotton fabric, wash it with 2g / L 209 detergent at 40°C for 5min, wash it with cold water, and dry it at 80°C;

[0044] (2) Attach the cotton fabric to a 22cm×22cm flat thin plastic plate, expose one side of it in the reaction chamber, take 100ml of D4 monomer and add it to the Erlenmeyer flask connected to the cold plasma, and heat it in a water bath at 90°C;

[0045] (3) Hang the cotton fabric protected on one side on the glass rod with plastic clips, put it into the cold plasma reaction chamber, vacuumize, and pass O when the pressure drops below 5Pa2 , after two gas cycles, adjust the valve, keep the pressure at a stable value of 20Pa, and then turn on the cold plasma radio frequency button to treat the cotton fabric, the time is 2min, and the power is 60W;

[0046] (4) After the discharg...

Embodiment 3

[0049] A kind of preparation method of single-sided super-hydrophobic single-sided hydrophilic Janus type fabric, concrete steps are as follows:

[0050] (1) Take a 20cm×20cm white knitted cotton fabric, wash it with 2g / L 209 detergent at 40°C for 5min, wash it with cold water, and dry it at 80°C;

[0051] (2) Attach the cotton fabric to a 22cm×22cm flat thin plastic plate, expose one side of it to the reaction chamber, take 100ml of D4 monomer and add it to the Erlenmeyer flask connected to the cold plasma, and heat it in a water bath at 85°C;

[0052] (3) Hang the cotton fabric protected on one side on the glass rod with plastic clips, put it into the cold plasma reaction chamber, vacuumize, and pass O when the pressure drops below 5Pa 2 , after two gas cycles, adjust the valve, keep the pressure at a stable value of 20Pa, and then turn on the cold plasma radio frequency button to treat the cotton fabric, the time is 2min, and the power is 80W;

[0053] (4) After the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com