Multi-drawing-wire conductor wire-stranding method

A multi-head wire drawing and stranded wire technology, used in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as low production efficiency, inconsistent tension, broken wires, etc., to save production sites, improve production efficiency, and save raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The method for stranding a multi-head wire drawing conductor in the present invention includes a wire drawing process and a wire stranding process.

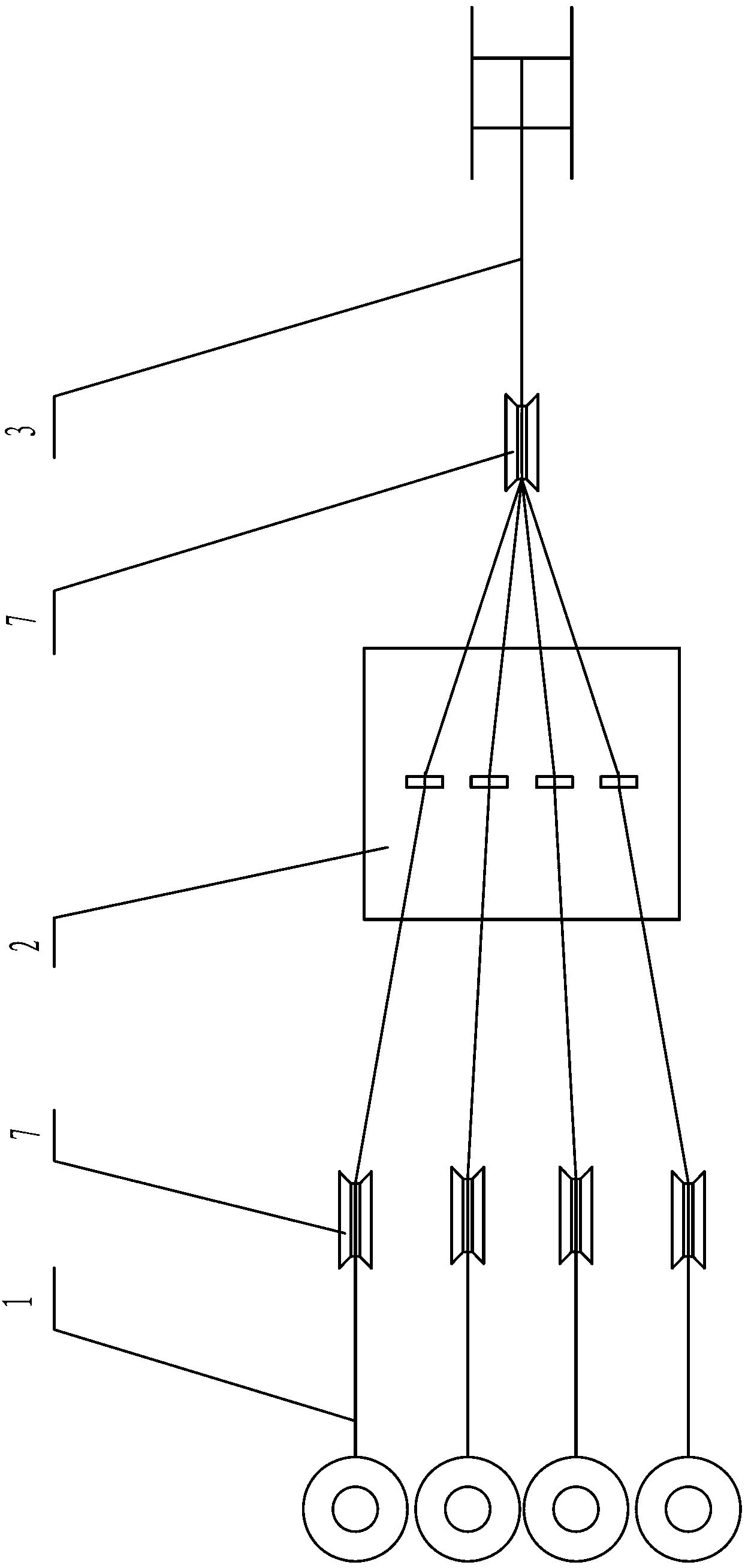

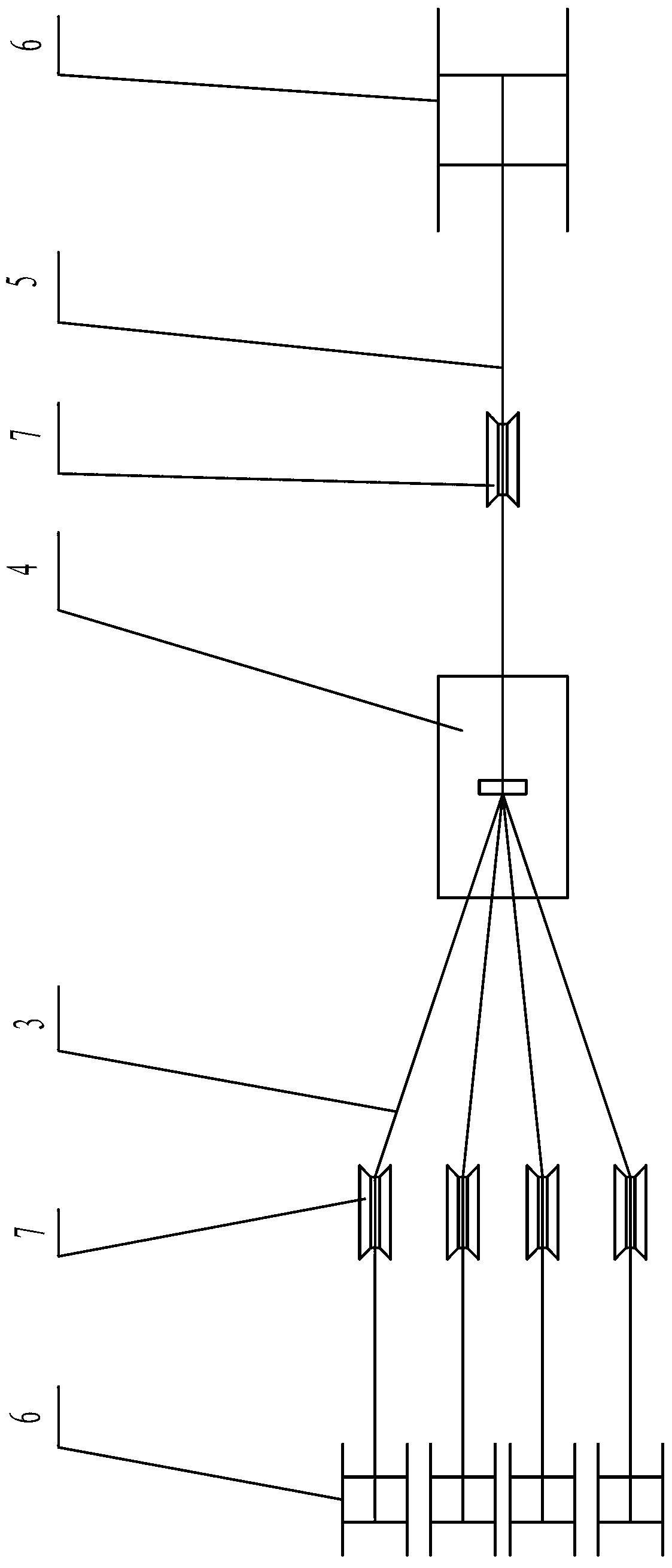

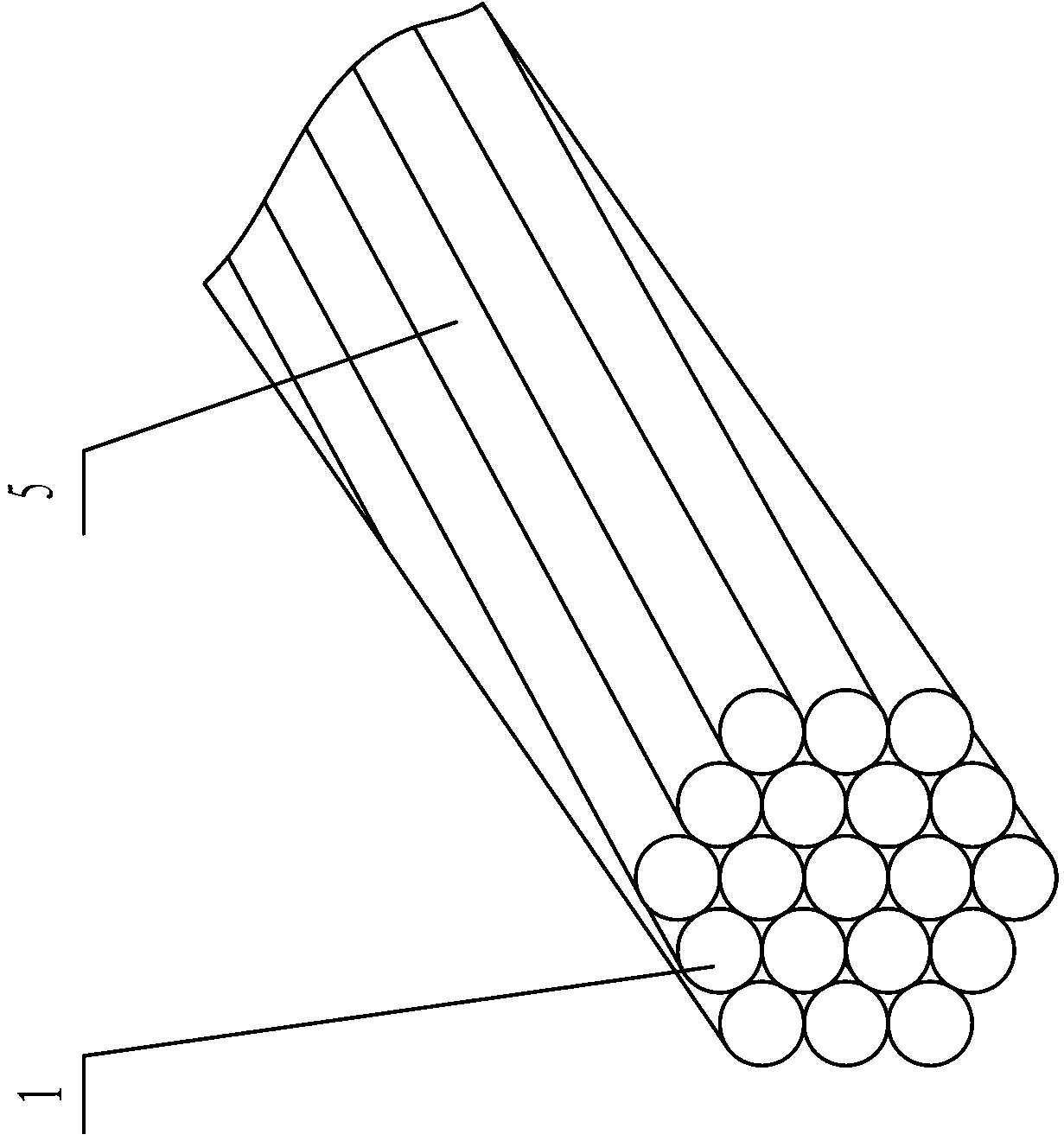

[0024] 1. The wire drawing process is that a plurality of metal wires 1 are respectively drawn and formed on a multi-head wire drawing machine 2 at one time, and the formed plurality of metal wires 1 are synthesized into a strand of metal wire 3 and wound up with a spool 6 .

[0025] Such as figure 1 As shown, after the four rolls of metal wire 1 are unrolled, they are guided by the corresponding guide wheels 7 respectively, and then enter the corresponding wire drawing dies on the multi-head wire drawing machine 2 for drawing and forming (the wire diameter is the same), and the four coils after drawing and forming The metal wire 1 is uniformly guided by a guide wheel 7, and is finally wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com