Stator winding of cylinder submersible linear electric machine with oil and its winding method

A linear motor and stator winding technology, which is applied in the direction of electric components, manufacturing of motor generators, shape/style/structure of winding conductors, etc., can solve the problems of inability to achieve high-power lift, affecting the cross-sectional area of wires, and occupying volume, etc. Achieve the effect of increasing power, unique winding structure and increasing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

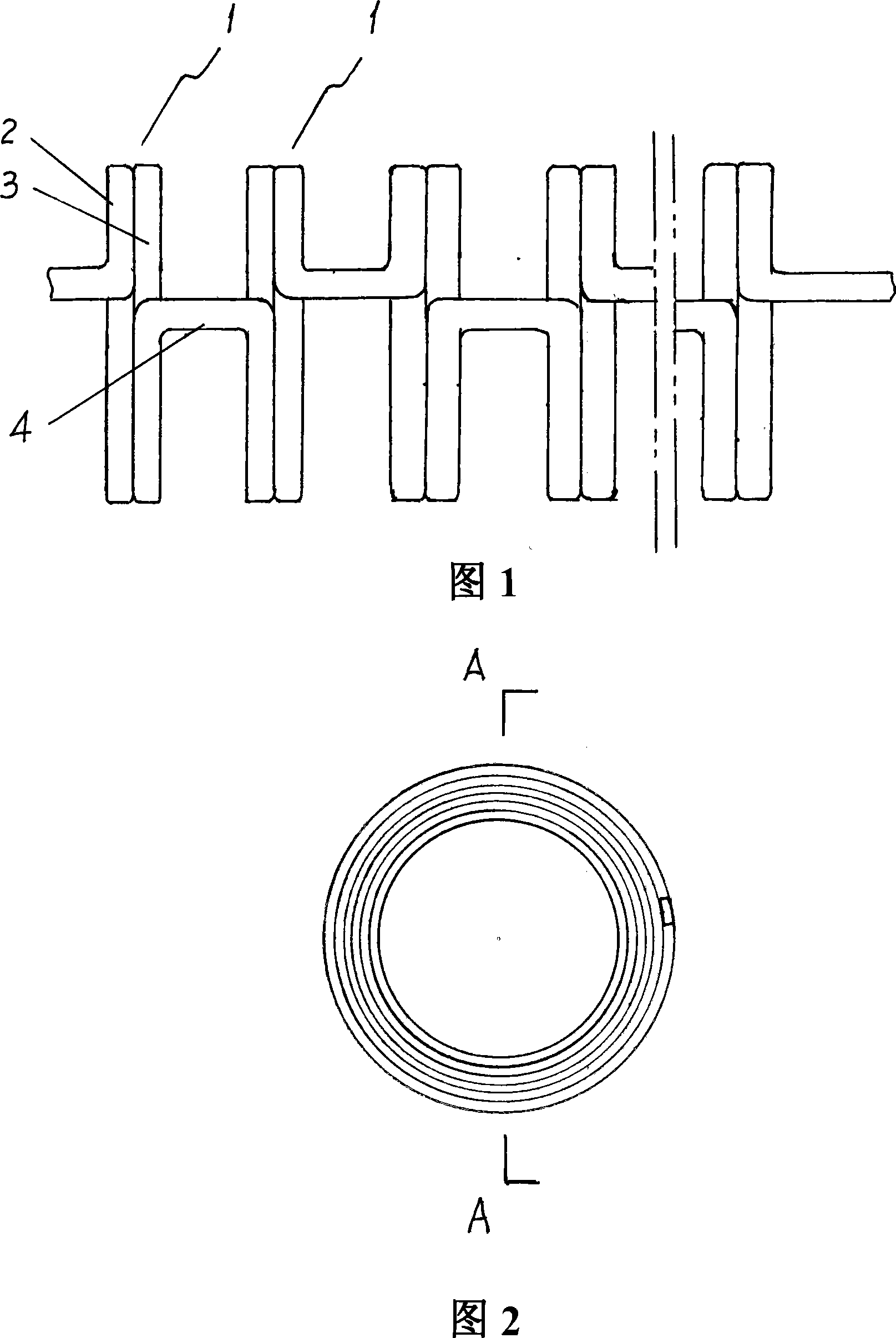

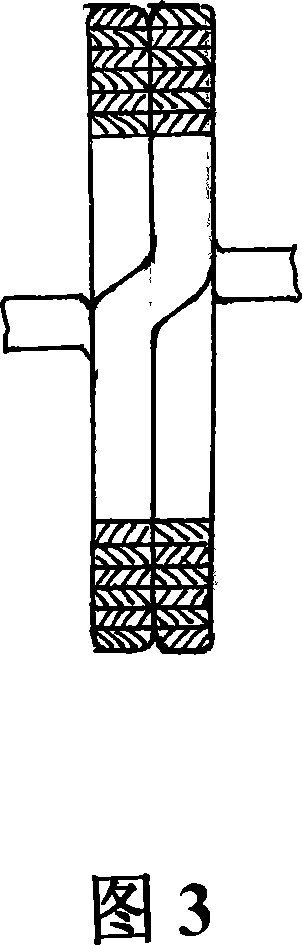

[0012] See Fig. 1, 2, the concrete structure of the stator winding provided by the present invention is as follows (this example is wherein a phase winding in the three-phase winding): the magnet wire that the stator coil winding adopts is a flat magnet wire. The entire coil winding is provided with a plurality of single-cake coils 1, and the lead-out lines at both ends of each single-cake coil 1 are arranged outside the circle, and the lead-out lines of each single-cake coil 1 are connected in series (that is, the connecting wires between the single-cake coils 4). Each single-cake coil 1 has a double-layer structure, one layer of coil 2 is a clockwise winding structure, and the other layer of coil 3 is a counterclockwise winding structure. The clockwise winding direction of one layer of coil 2 is converted to the counterclockwise winding direction of another layer of coil 3. An S-bend is set at the starting point of the innermost circle, and its structure is shown in FIG. 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com