Novel unequal-area transposition flat wire winding permanent magnet motor

A technology of flat wire winding and permanent magnet motor, which is applied to the shape/style/structure of winding, winding insulation, shape/style/structure of winding conductor, etc. Larger, lower motor efficiency and other issues, to achieve the effect of reducing eddy current loss, reducing motor temperature rise, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

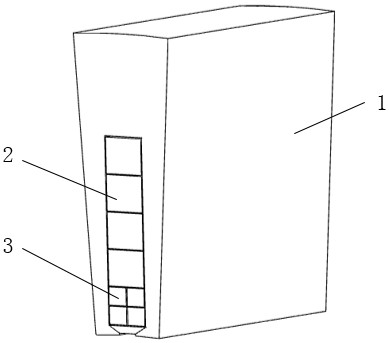

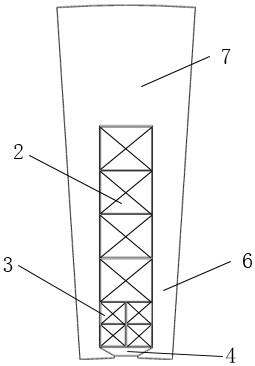

[0025] see figure 1 , in the embodiment of the present invention, a new permanent magnet motor with unequal area transposition flat wire winding, including stator core (1), insulation, slot wedge (4) and flat wire winding, wherein the stator core, insulation, slot The wedge and the flat wire winding together constitute the stator part of the permanent magnet motor. The stator core includes the stator core tooth part (6) and the stator core yoke part (7), and the stator core tooth part and the stator core yoke part The gap constitutes the stator core slot (8), which is characterized in that the stator winding includes 4 sets of large-area flat wire windings and two sets of strand flat wire windings arranged inside the stator core slot of the stator core, and the strand flat wire The thickness of the winding 3 is smaller than that of the large-area flat wire winding 2, and the insulation is divided into slot insulation arranged inside the stator core slot and winding insulation ...

Embodiment 2

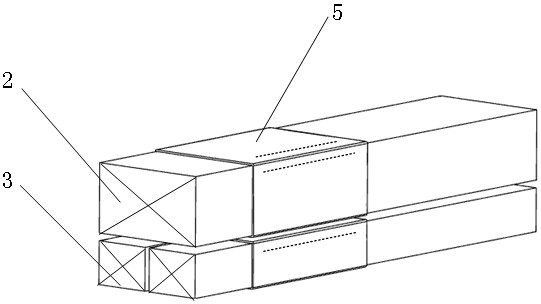

[0030] Further improvements have been made on the basis of Embodiment 1, please refer to Figure 5 and Image 6 , with a transposition structure of unequal-area subdivided flat wire windings, there are 6 layers of flat wire windings along the radial direction of the motor in the slot, and the 2 layers of flat wire windings near the slot are divided into 2 strands The 4-layer large-area flat wire winding in the middle of the slot and at the bottom of the slot is a whole piece of flat wire winding. Because the windings of the split flat wires are connected in parallel, a circulating current will be generated between the windings of the strands, and the circulating current is reduced by means of end twisting and transposition. The specific transposition connection method is as follows: the original split flat wire winding is divided into two flat wire windings in the circumferential direction, which are numbered sequentially. The first layer is numbered 1-1, 1-2, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com