Automatic wire winding device of motor stator

A technology of automatic winding and motor stator, applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve the problems of low full rate of stator slots, high labor intensity, low efficiency, etc., and achieve high full rate of finished stator slots. , The effect of low labor intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

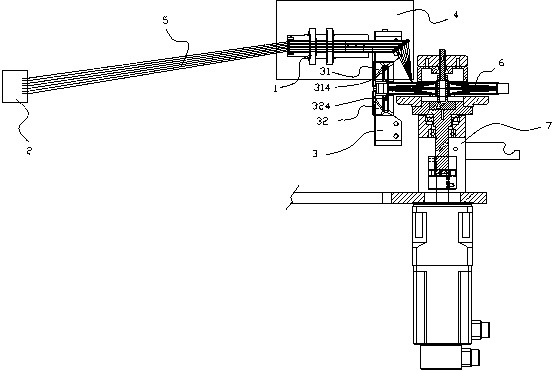

[0023] Such as figure 1 As shown, an automatic winding device for a motor stator includes a wire winding mechanism and a stator positioning mechanism.

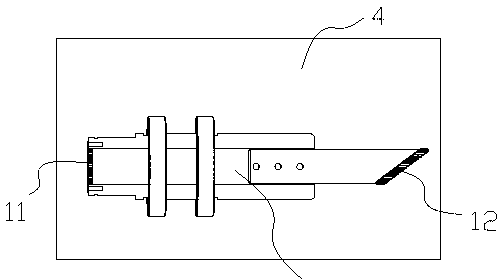

[0024] The wire winding mechanism is composed of a moving nozzle 1 , a wire compactor 2 and a wire guide 3 . The moving nozzle 1 can rotate relative to itself and is arranged on a two-axis moving device 4 that can make it move in a plane relative to a vertical plane. The interior of the whole moving wire nozzle 1 is hollow, and the two ends are respectively provided with a single-row wire inlet hole 11 and a single outlet wire hole 12 for a single row of wires 5, and its structure is as follows image 3 shown.

[0025] A spring buffer device is arranged inside the wire compactor 2 , and the entire wire compactor 2 is arranged at a certain distance relative to the moving nozzle 1 .

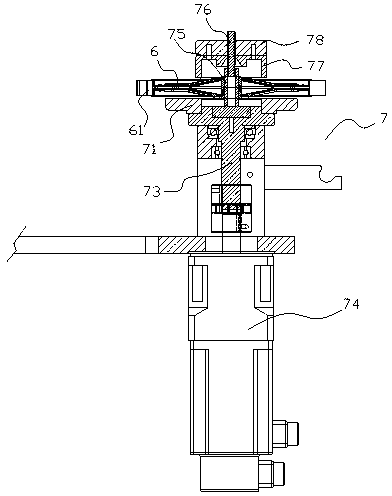

[0026] Such as Figure 4 As shown, the thread-laying guide 3 is divided into an upper guide 31 and a lower guide 32, and the upper and lower g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com