Permanent magnet motor stator structure

A technology of stator structure and permanent magnet motor, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of motor efficiency, mechanical overall strength, unsatisfactory performance, low mechanical performance, poor mechanical strength, etc. , to achieve the effect of ingenious design, simple structure and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

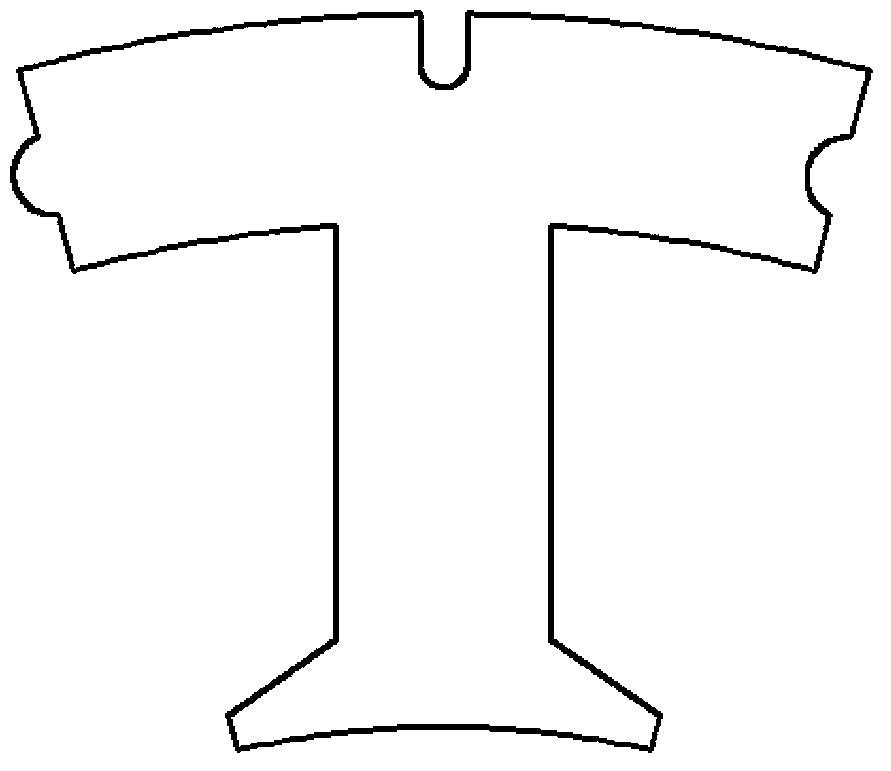

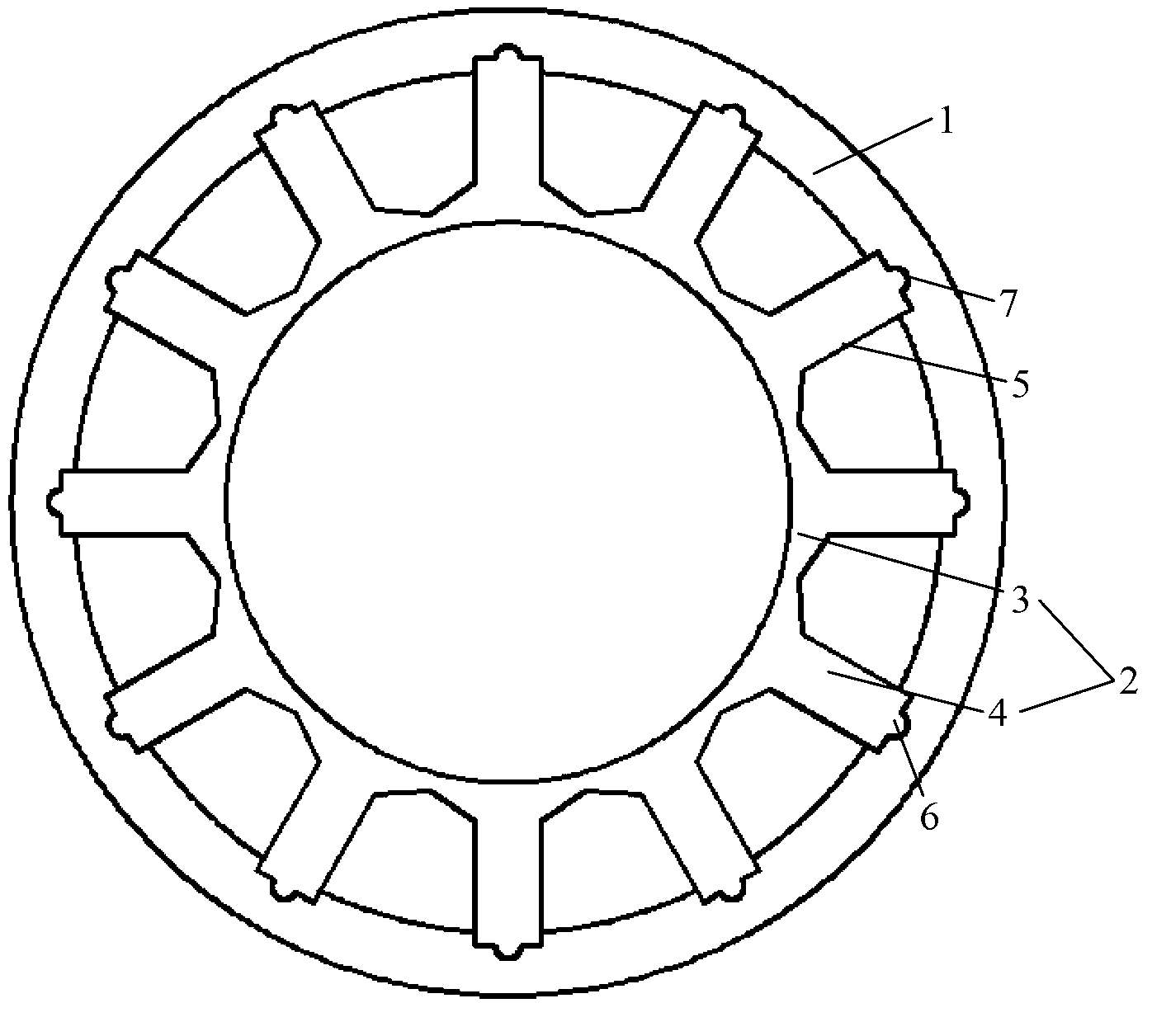

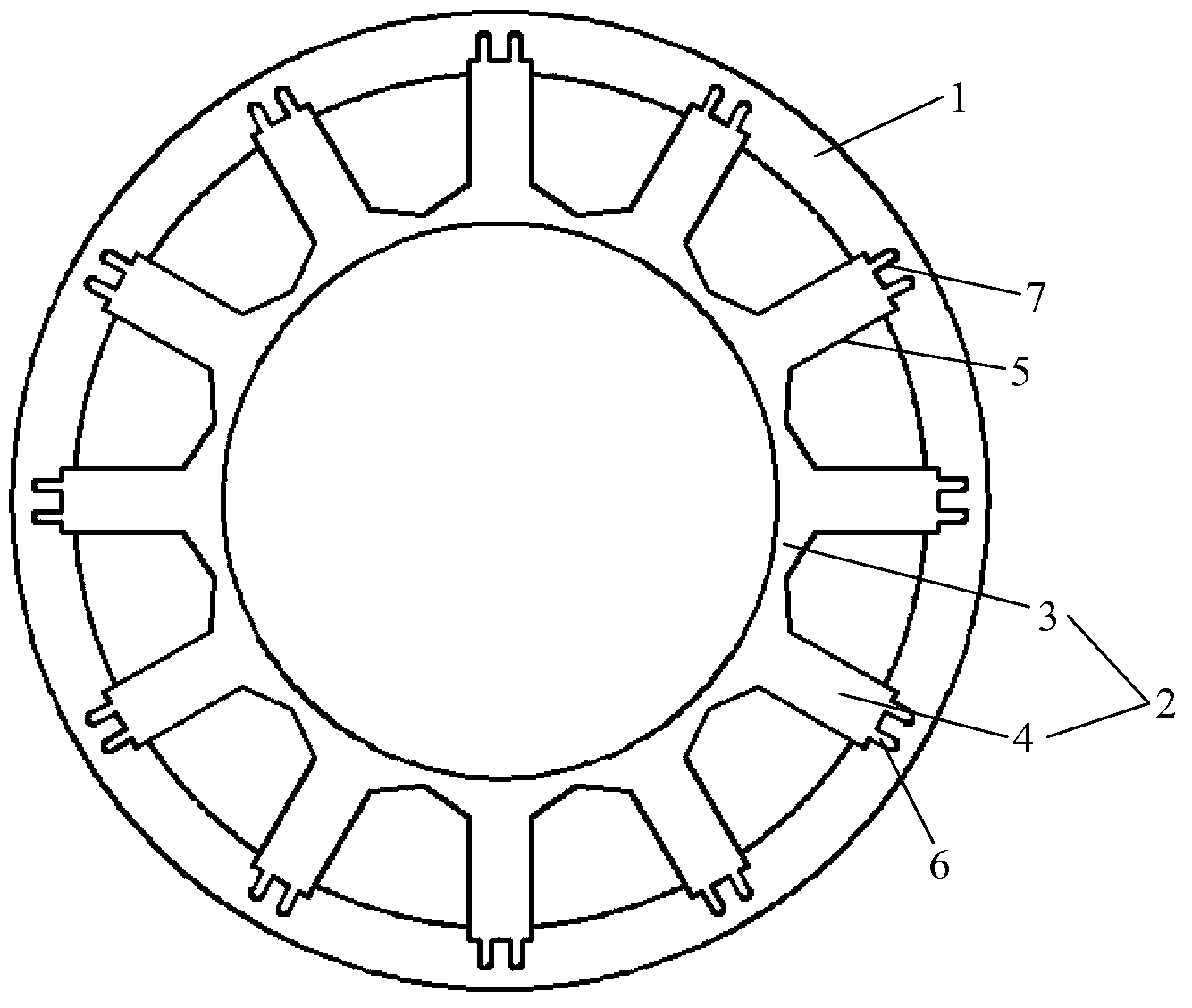

[0025] See Figure 2-Figure 4 As shown, the permanent magnet motor stator structure of the present invention includes a stator yoke 1 and a stator ring 2, and the stator ring 2 includes a ring base 3 and several stator teeth extending radially outward from the ring base 3 4. The stator yoke 1 is sleeved outside the stator gear ring 2, and the inner surface of the stator yoke 1 is provided with fixing grooves 5 having the same number as the stator teeth 4 and matching in shape. The stator teeth 4 are inserted in the fixing slots 5 and are in close contact with each other.

[0026] To further increase the contact area and reduce the effect on permanent magnet flux linkage, see Figure 2-Figure 4 As shown, in the first to third specific embodiments of the present invention, the top of the stator tooth 4 has a convex portion 6, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com