A lobe split combination stator

A technology of combining stators and lobes, applied in the shape/pattern/structure of electric components, winding conductors, magnetic circuit shape/pattern/structure, etc. The problem of low utilization rate, etc., can reduce vibration and noise, fix firmly, and reduce the cost of mold input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be described in further detail with reference to the drawings and embodiments:

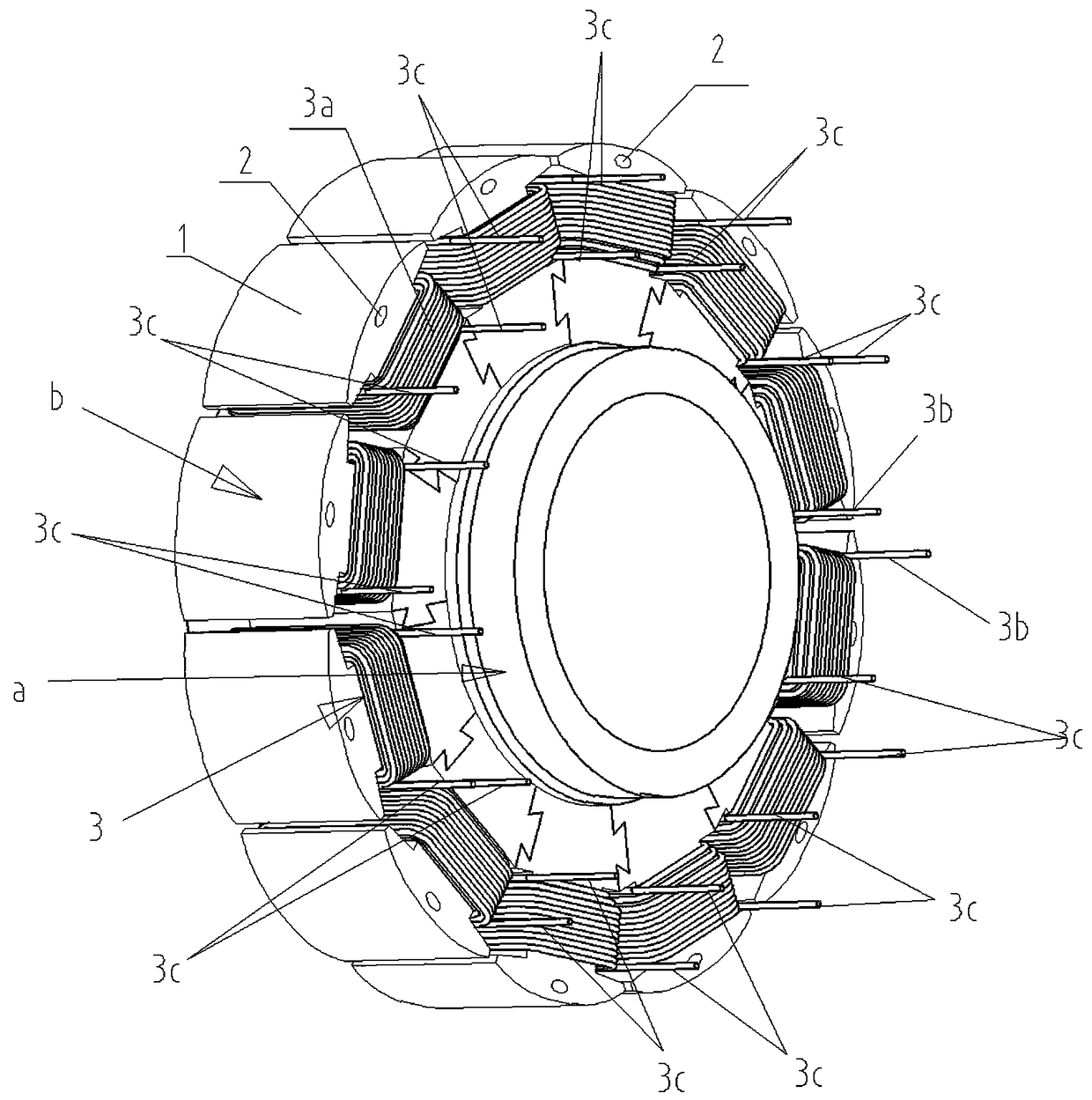

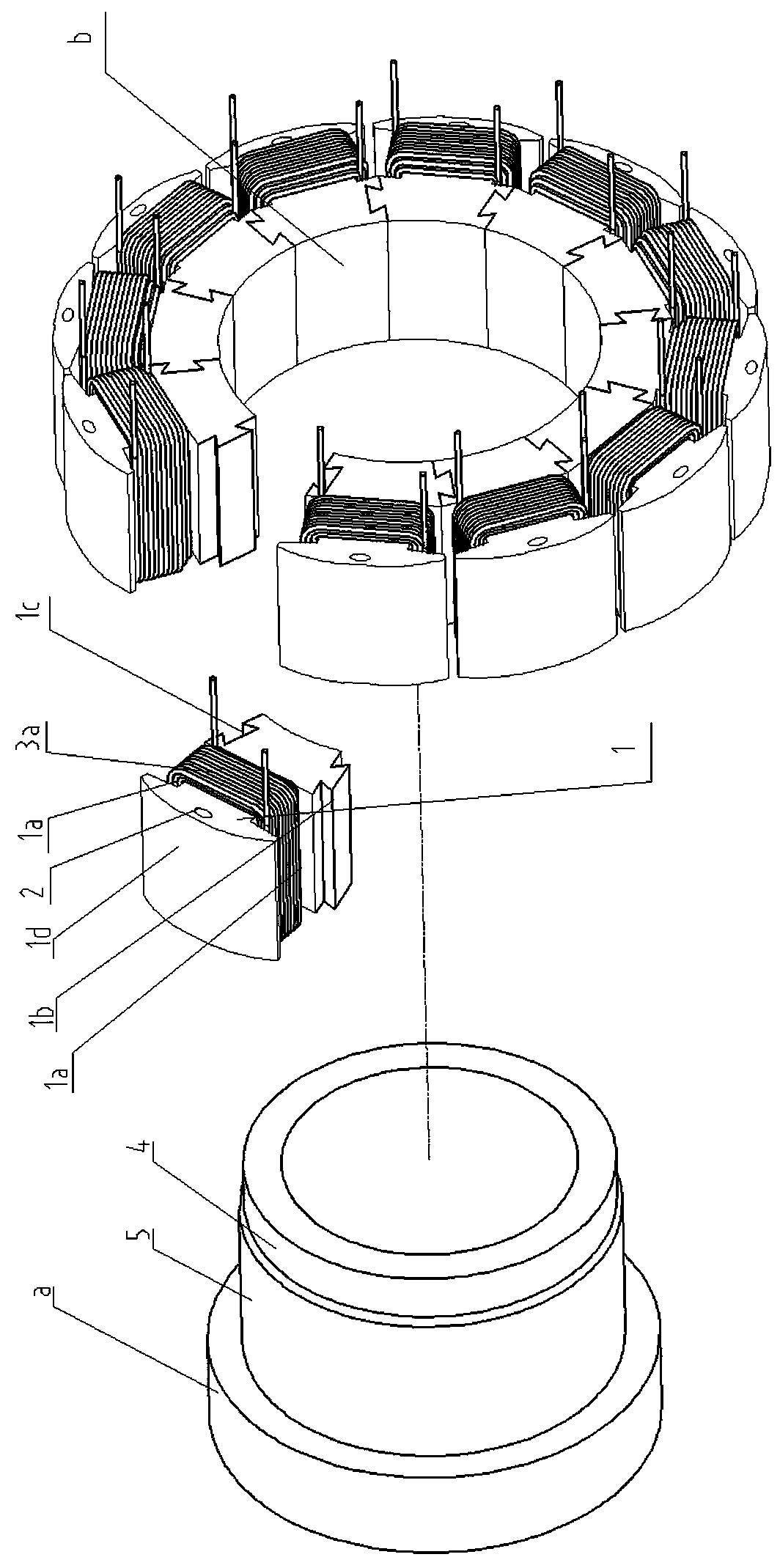

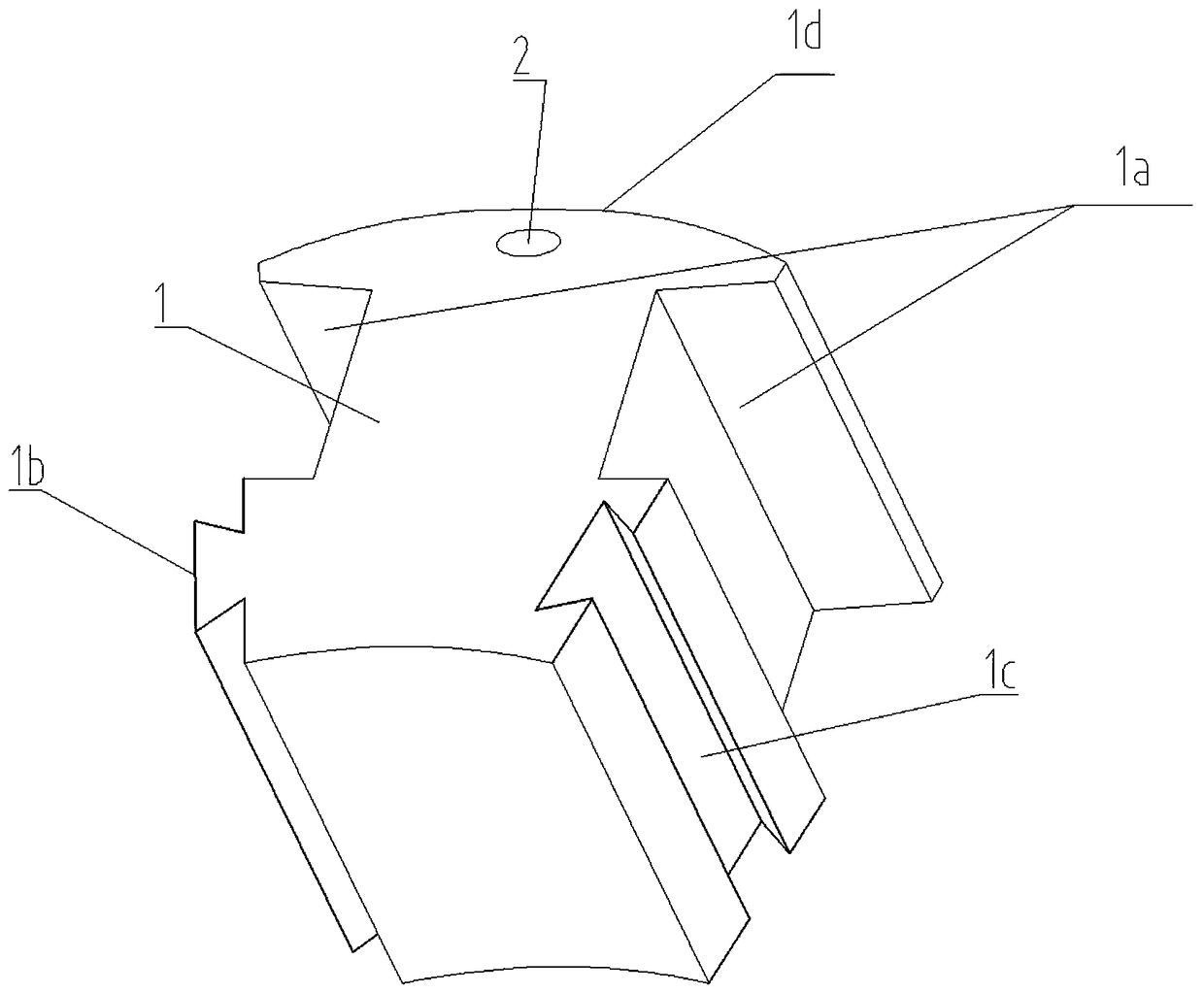

[0022] Such as figure 1 As shown in —3, the present invention includes a ring-shaped expansion sleeve a, a ring-shaped stator core b formed by connecting several fan-shaped iron core units 1 in series with each other. The fan-shaped iron core unit 1 is composed of several punched sheets laminated together The two sides of the fan-shaped core unit 1 are provided with grooves 1a in the middle, and the grooves 1a are used to wind the stator coil 3. The two sides of the lower part of the fan-shaped core unit 1 are respectively provided with tenons 1b and grooves 1c. The iron core unit 1 is inlaid with each other through the tenon 1b and the tenon groove 1c. A certain number of fan-shaped split fan-shaped iron core units 1 are combined to form an annular stator iron core b, and the groove 1a of the fan-shaped iron core unit 1 is wound There are stator coil windings 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com