Winding device of armature and method

A technology of a winding device and a winding method, applied in the directions of electromechanical devices, electrical components, electric components, etc., can solve the problem of difficulty in improving the full rate of the slot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

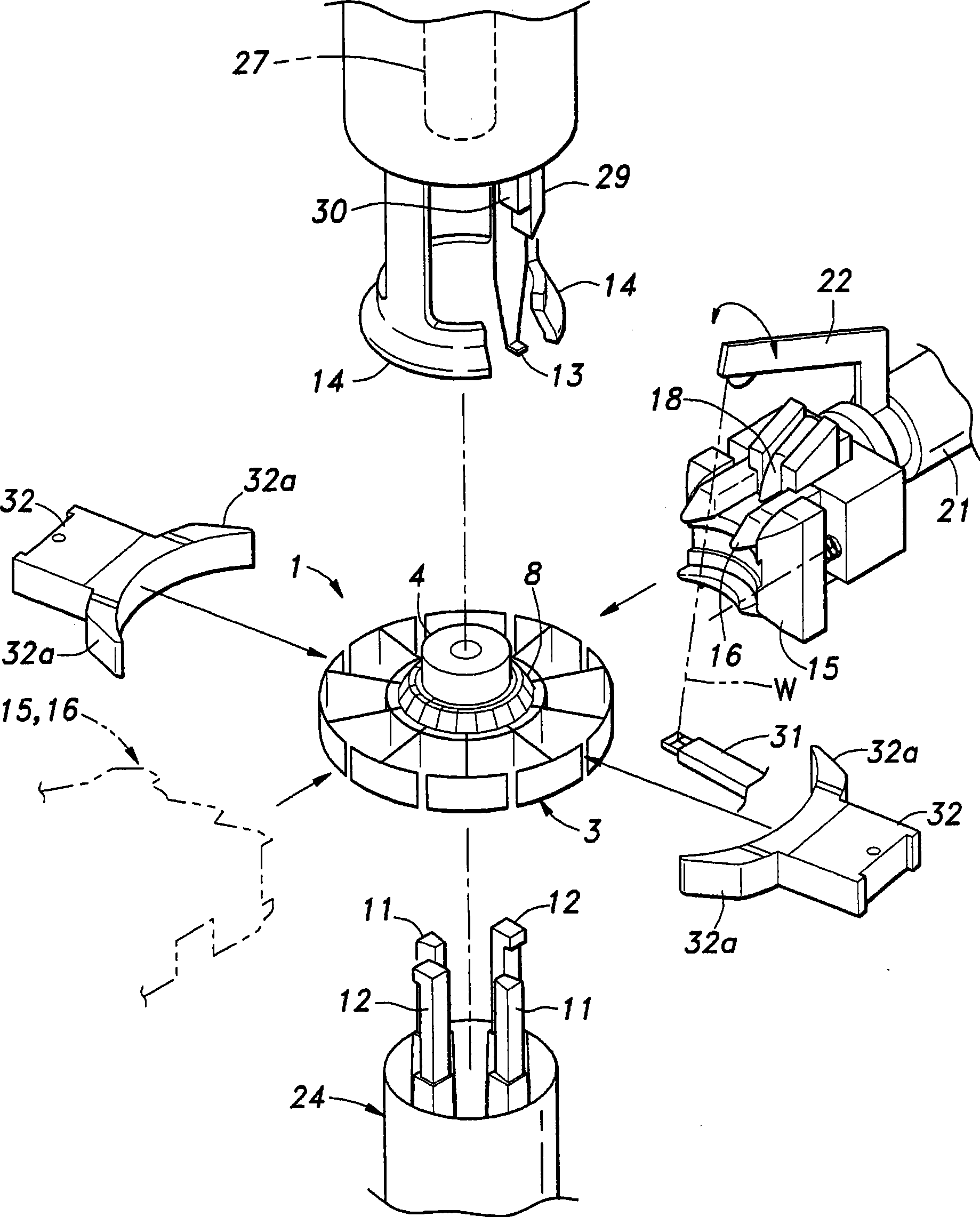

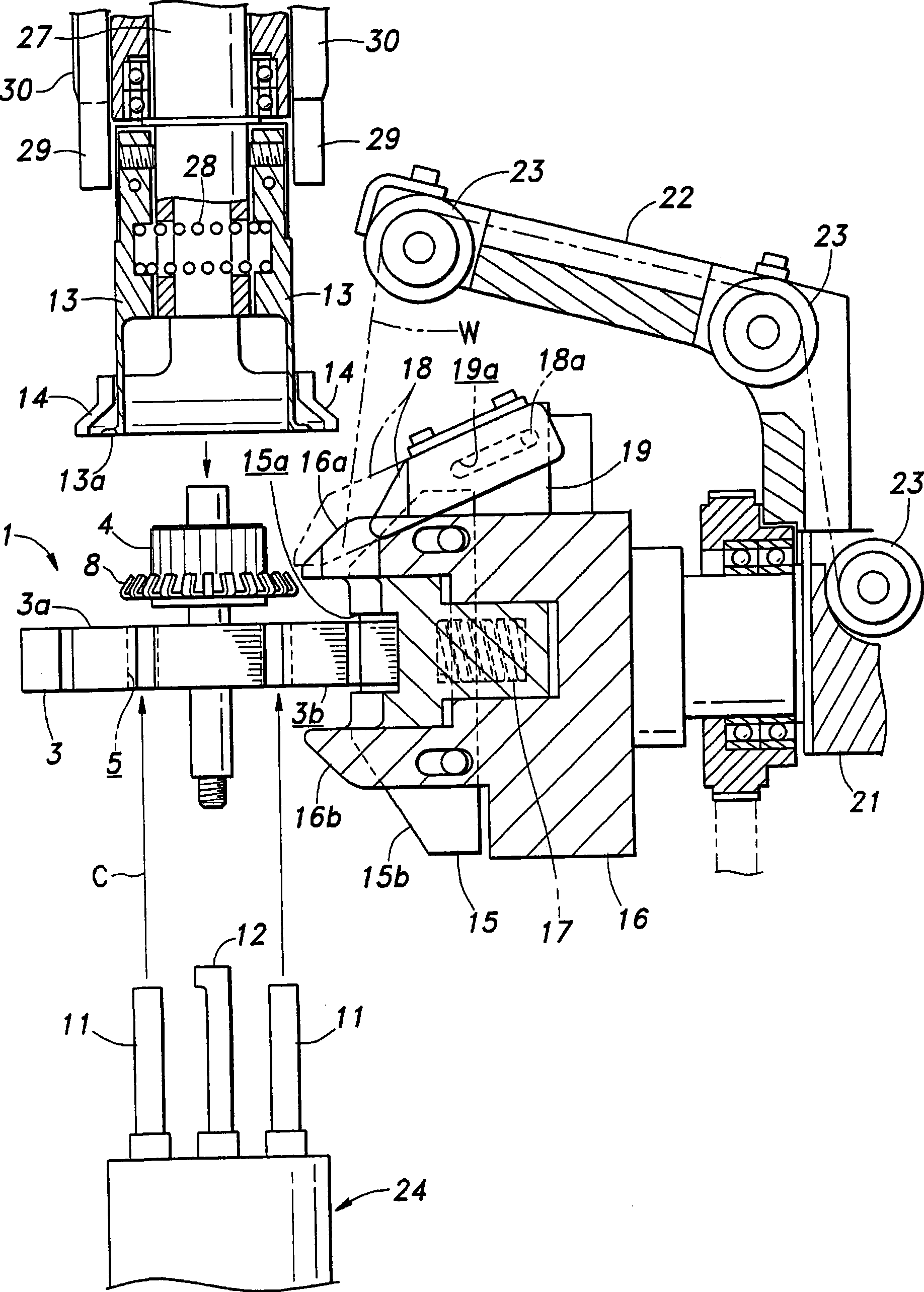

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a figure which schematically and schematically shows the whole of the winding device to which this invention was applied. The armature 1 to be wound by this device is a flat type as shown in the figure, and is used in a flat motor whose axial direction is shorter than the outer diameter.

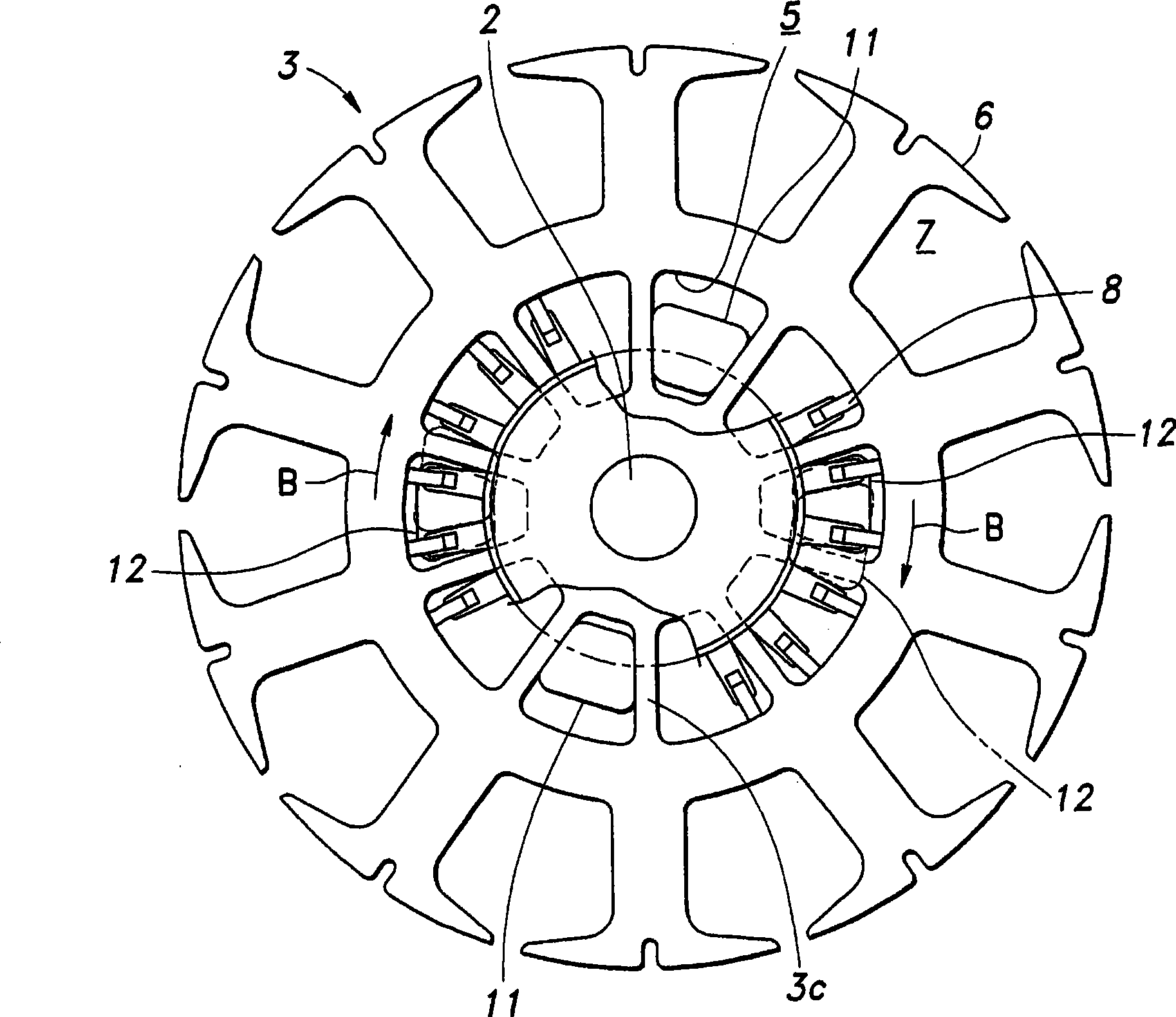

[0029] such as with figure 2 with image 3 As shown together, the armature 1 has a thin, large-diameter iron core 3 and a small-diameter commutator 4 , which are arranged coaxially and fixed on the shaft 2 . The iron core 3 of the illustrated example is an iron core formed by laminating steel sheets. The iron core 3 has an annular wall on a circumference passing through a substantially midpoint in the radial direction. A plurality of axial through holes 5 penetrating the axial direction of the iron core 3 are provided at equal intervals in the direction, and a predete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com